Full balanced energy saver for beam-pumping unit

A technology of beam pumping unit and energy-saving device, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of no negative torque, load rate and low work efficiency and energy consumption, so as to avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

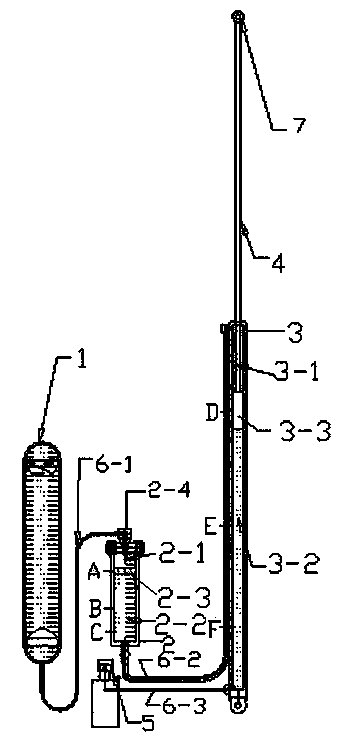

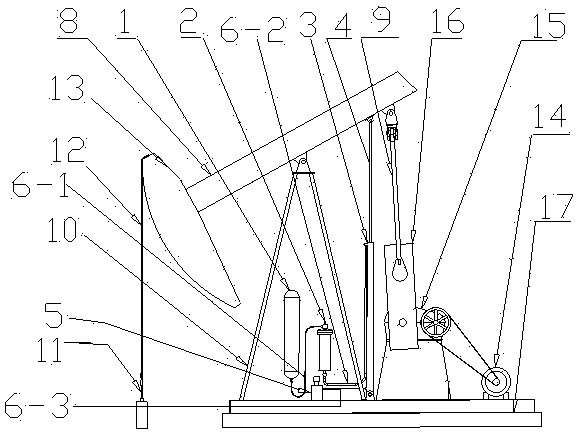

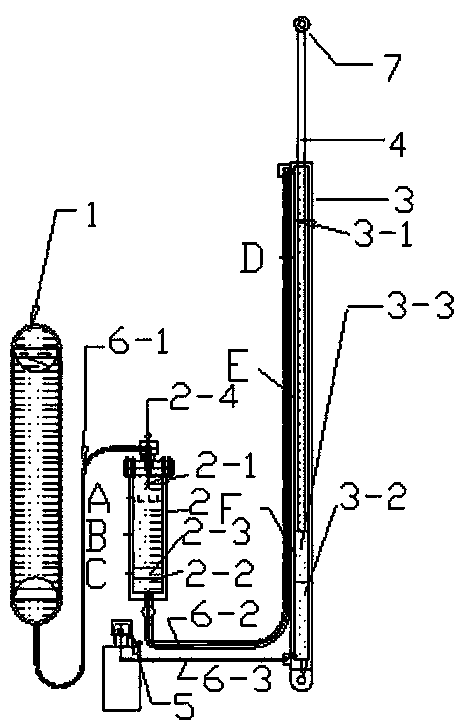

[0013] Combine below figure 1 , image 3 Explain that the device, the full balance energy-saving device of the beam pumping unit, is mainly composed of an air storage tank 1, a balance cabin 2, a hydraulic cylinder 3, a piston rod 4, a filter 5 and pipelines. The balance cabin 2 is equipped with The balance cabin piston 2-3 divides the balance cabin into an upper cabin 2-1 and a lower cabin 2-2. A pressure gauge 2-4 is provided on the top of the balance cabin to facilitate the control of the gas storage tank 1 and the upper cabin 2-2 of the balance cabin. 1 The pressure of the added inert gas and

[0014] The amount of gas added, the inert gas can be nitrogen or argon. The gas storage tank 1 communicates with the upper cabin 2-1 of the balance cabin through the first pipeline 6-1 at the lower end, and its space is filled with inert high-pressure gas, so that the gas storage tank 1 and the upper cabin 2-1 of the balance cabin 2 Keep the pressure the same. The lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com