NOx reduction control system for boilers

a technology of nox reduction and control system, which is applied in the direction of furnaces, flue gas purification components, separation processes, etc., can solve the problems of known as “ammonia slip” and achieve the effect of accurate nox reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

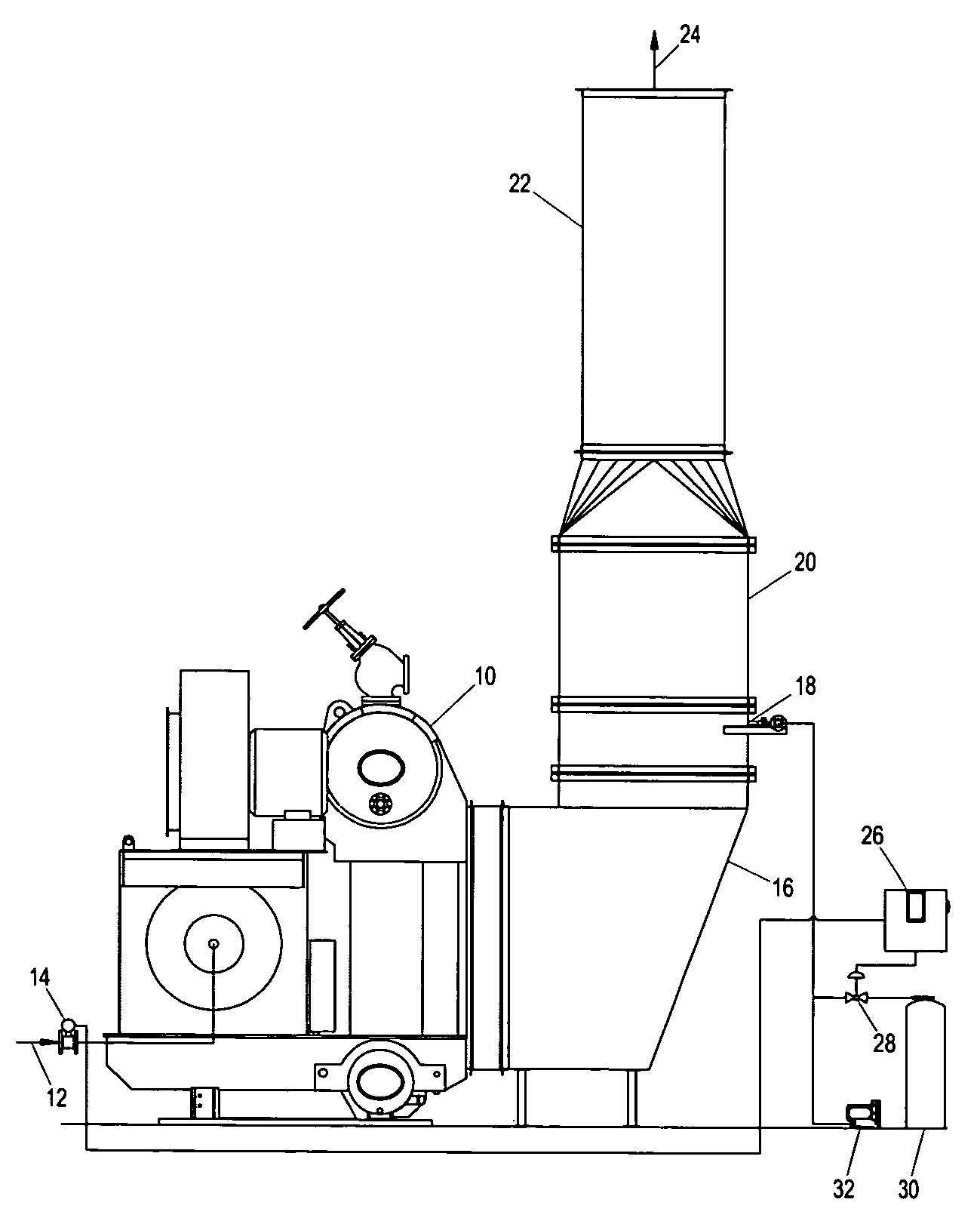

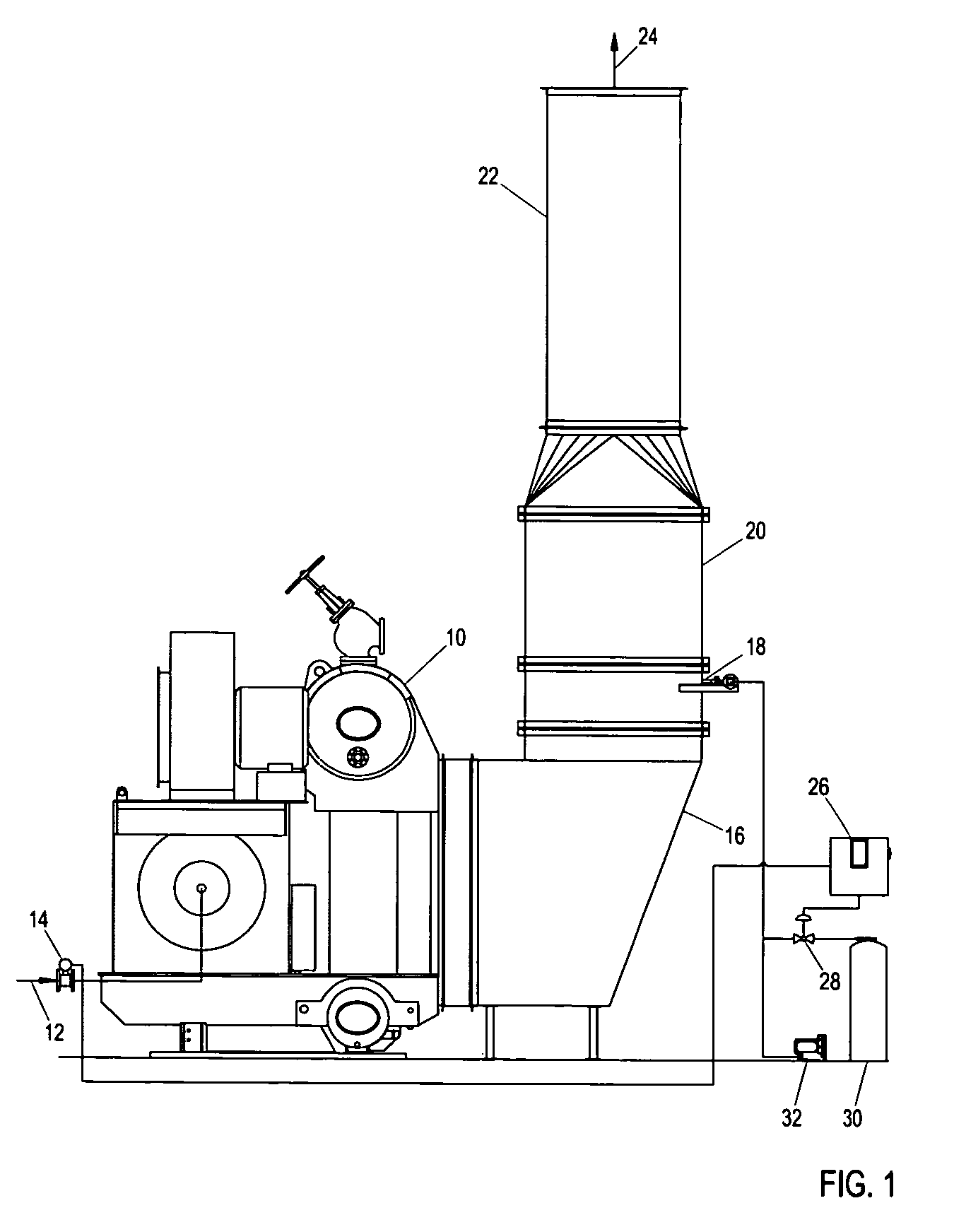

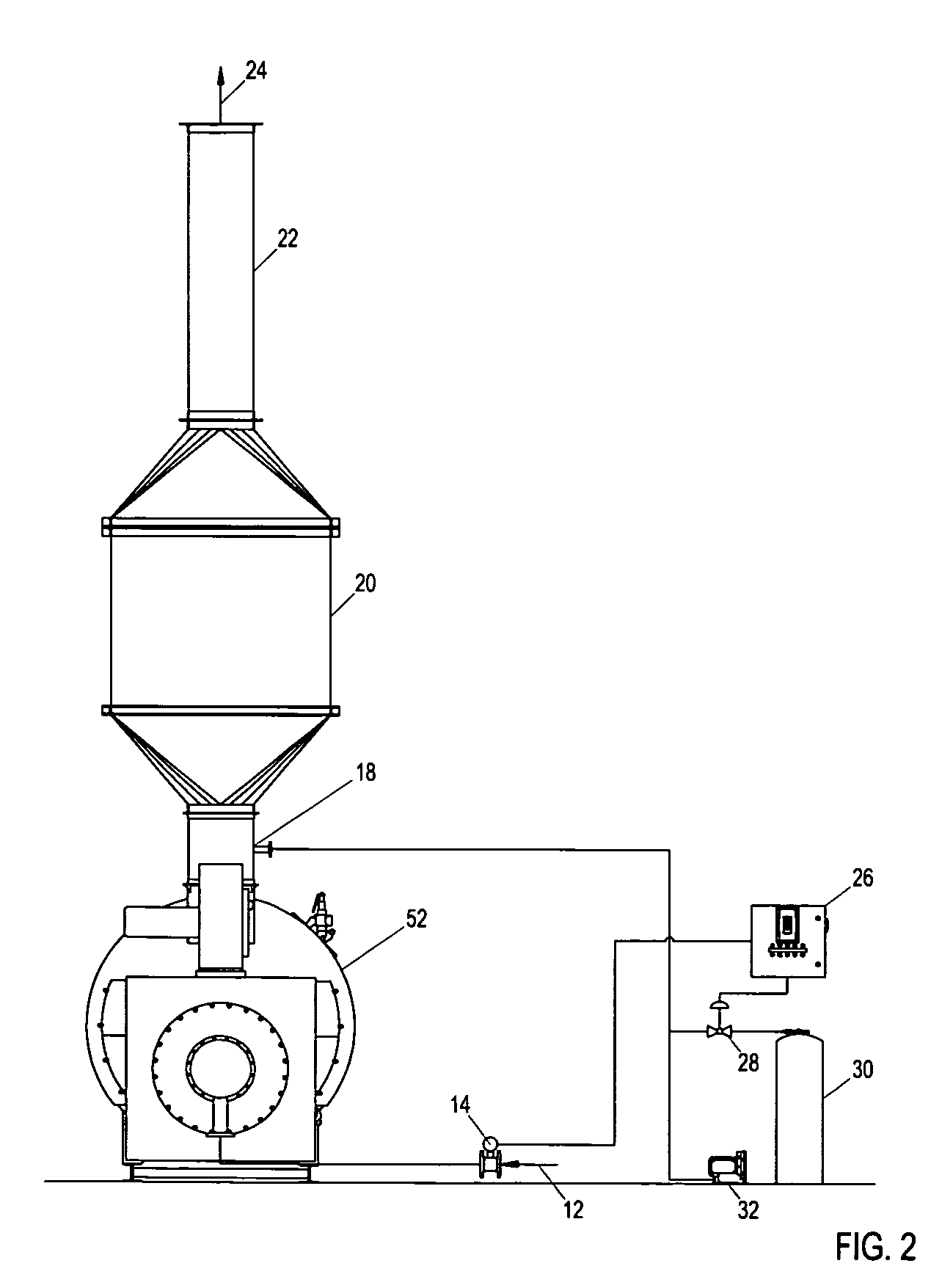

[0021]The invention uses an analog signal directly from a fuel flow device (or similar fuel flow measuring device) to control ammonia for NOx reduction. The control system can also use an alternate analog load signal from the boiler master control, plant master or plant digital control system (better known as a plant or boiler DCS). With the boiler in either manual or automatic operation, the control system receives a signal directly from the fuel flow device indicating the amount of fuel burning and corresponding NOx emissions. The signal is processed using an algorithm with a multi-loop, configurable controller and a mass flow control valve designed with temperature and pressure correction to determine the accurate amount of ammonia to be injected into the flue gas to achieve the desired performance. Air transports the ammonia to an injection grid and subsequently, a mixture of ammonia and flue gas is passed over a catalyst bed, which performs a chemical reaction and reduces NOx e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com