Application of conformal sub boundary layer vortex generators to a foil or aero/ hydrodynamic surface

a sub-border layer and generator technology, applied in the field of aero/hydrodynamic surfaces, can solve the problems of adverse effects of the resultant flow, achieve the effects of reducing the onset of the tip vortex rollup, and improving the lift and drag ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

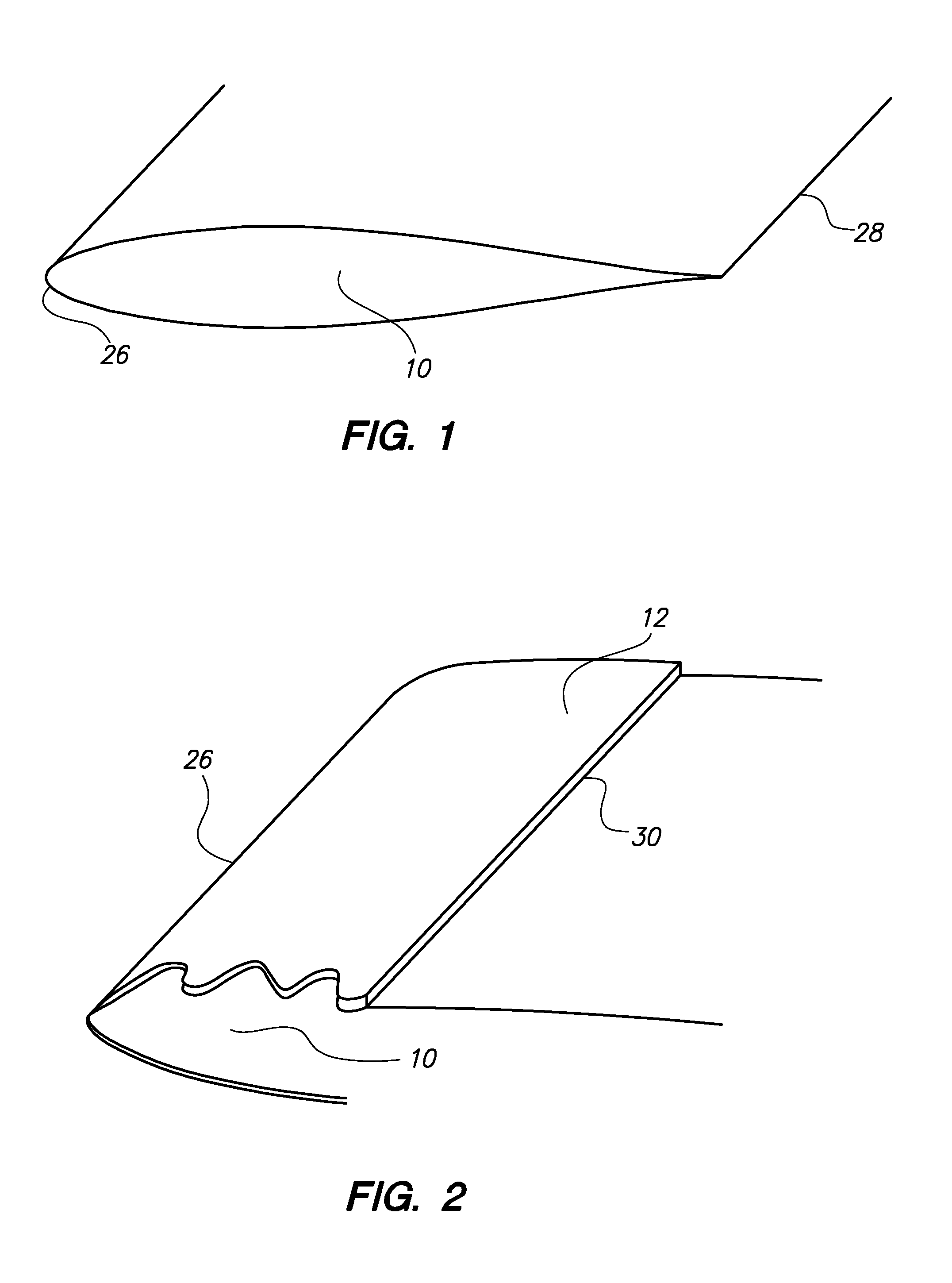

[0055]FIG. 1 is a top perspective view of a generic foil. This drawing shows the foil leading edge 26, foil or aero / hydrodynamic surface 10, and foil trailing edge 28.

[0056]FIG. 2 is a top perspective view of a foil with a current art erosion protection layer 12 or tape applied, to a foil or aero / hydrodynamic surface 10. It can be seen that the process of placing a tape around a foil leading edge 26 results in two aft facing edge 30 elements being produced, on the upper and lower faces of the foil or aero / hydrodynamic surface 10.

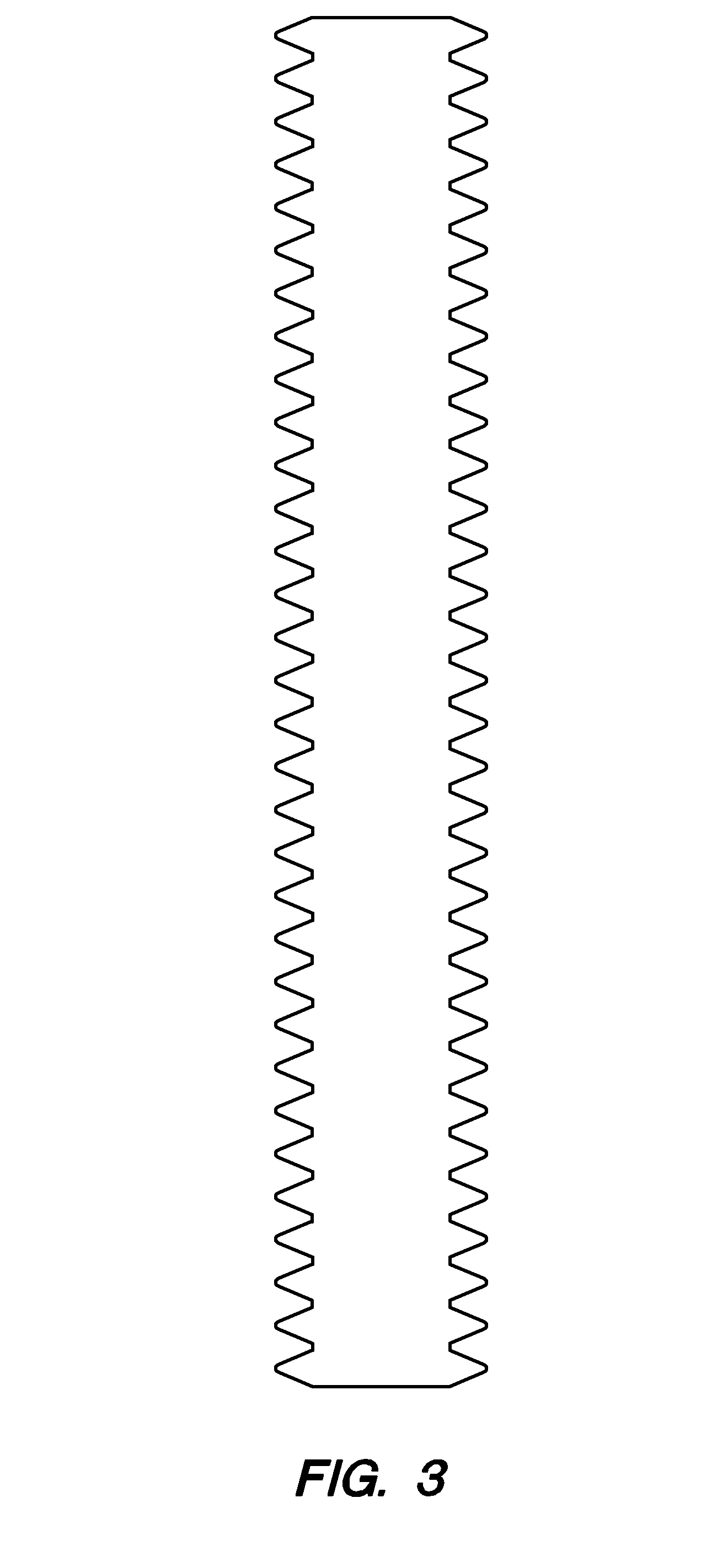

[0057]FIG. 3 is a top plan view of an elastomeric erosion protection layer 12 tape or application medium 14 tape element incorporating sub boundary vortex generators.

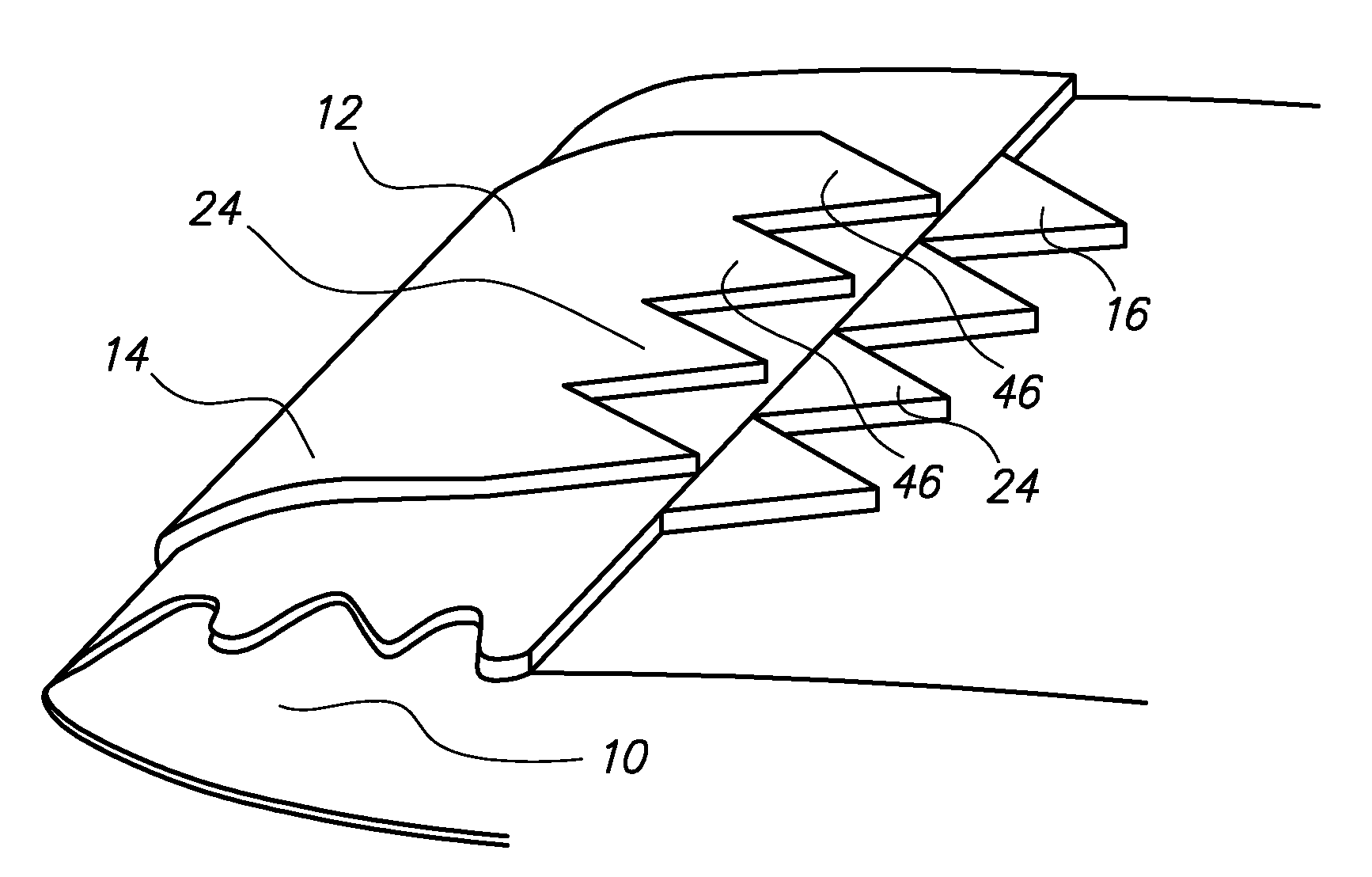

[0058]FIG. 4 is a top perspective view of a current art erosion protection tape with v form sub boundary layer vortex generators 16 applied at the aft facing edge 30. sub boundary layer vortex generators 24 are applied abutted in this case to the aft facing step or lapjoint 48 of the structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com