Self-cleaning protective coatings for use with photovoltaic cells

a photovoltaic cell and self-cleaning technology, applied in the direction of pv power plants, solid-state devices, transportation and packaging, etc., can solve the problems of reducing the efficiency of larger planar photovoltaic cells, difficult to make semiconductor films, and crystalline silicon-based cells, so as to reduce the laborious time-consuming cleaning and repainting efforts, maintain the efficiency of photovoltaic cells, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention provides systems and materials to improve photovoltaic cell performance by implementing a self-cleaning function on photovoltaic cells and / or on albedo surfaces in the vicinity of photovoltaic cell assemblies. One aspect of the invention provides materials for protecting albedo surfaces that surround photovoltaic cell assemblies, thereby maximizing energy input into the photovoltaic cell assemblies. Another aspect of the invention provides materials for self-cleaning photovoltaic cell panels, thereby maintaining their efficiency. A third aspect of the present invention provides designs for portable albedo collecting devices that are associated with photovoltaic cell assemblies to optimize energy efficiency.

5.1 General Architecture

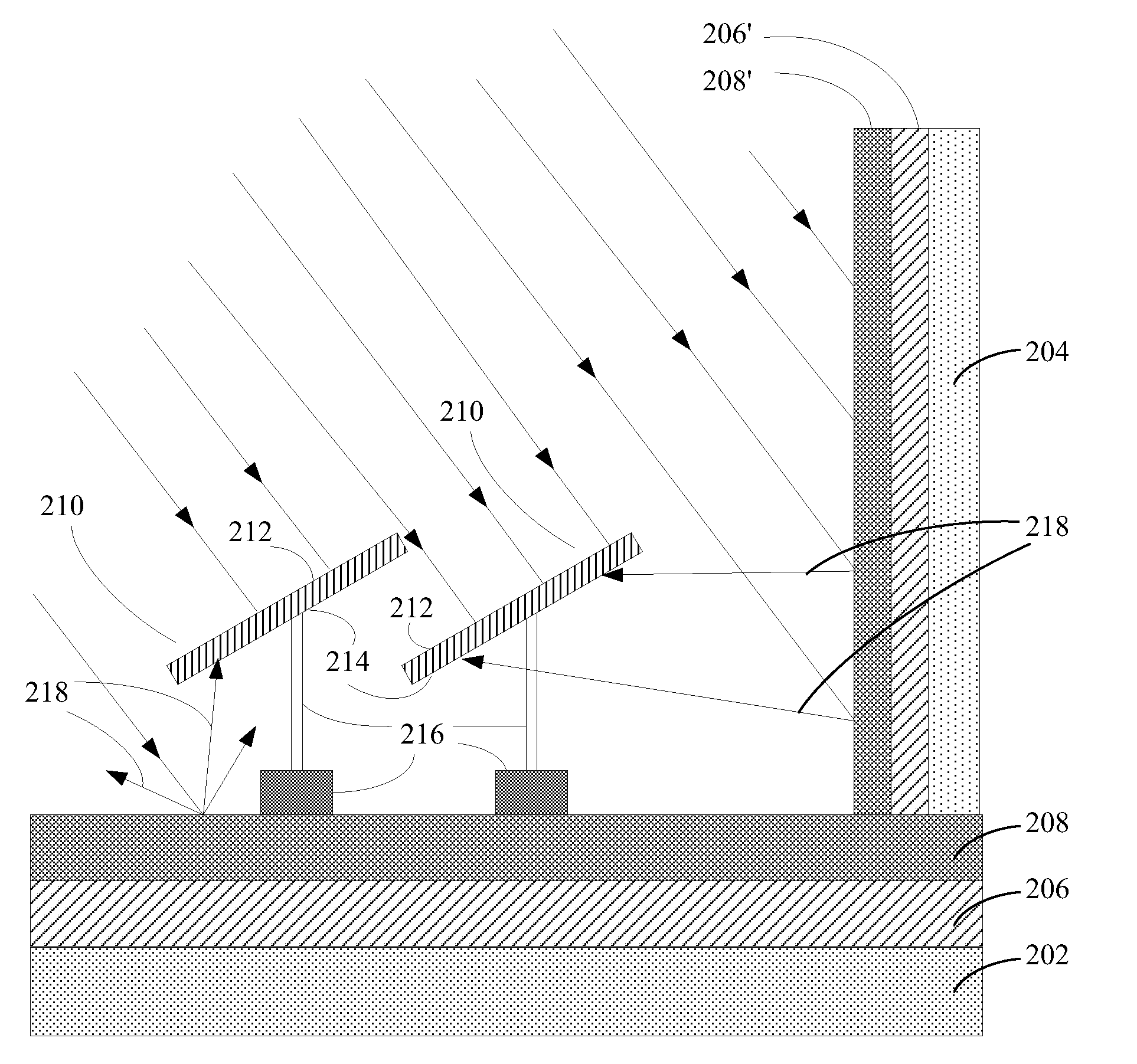

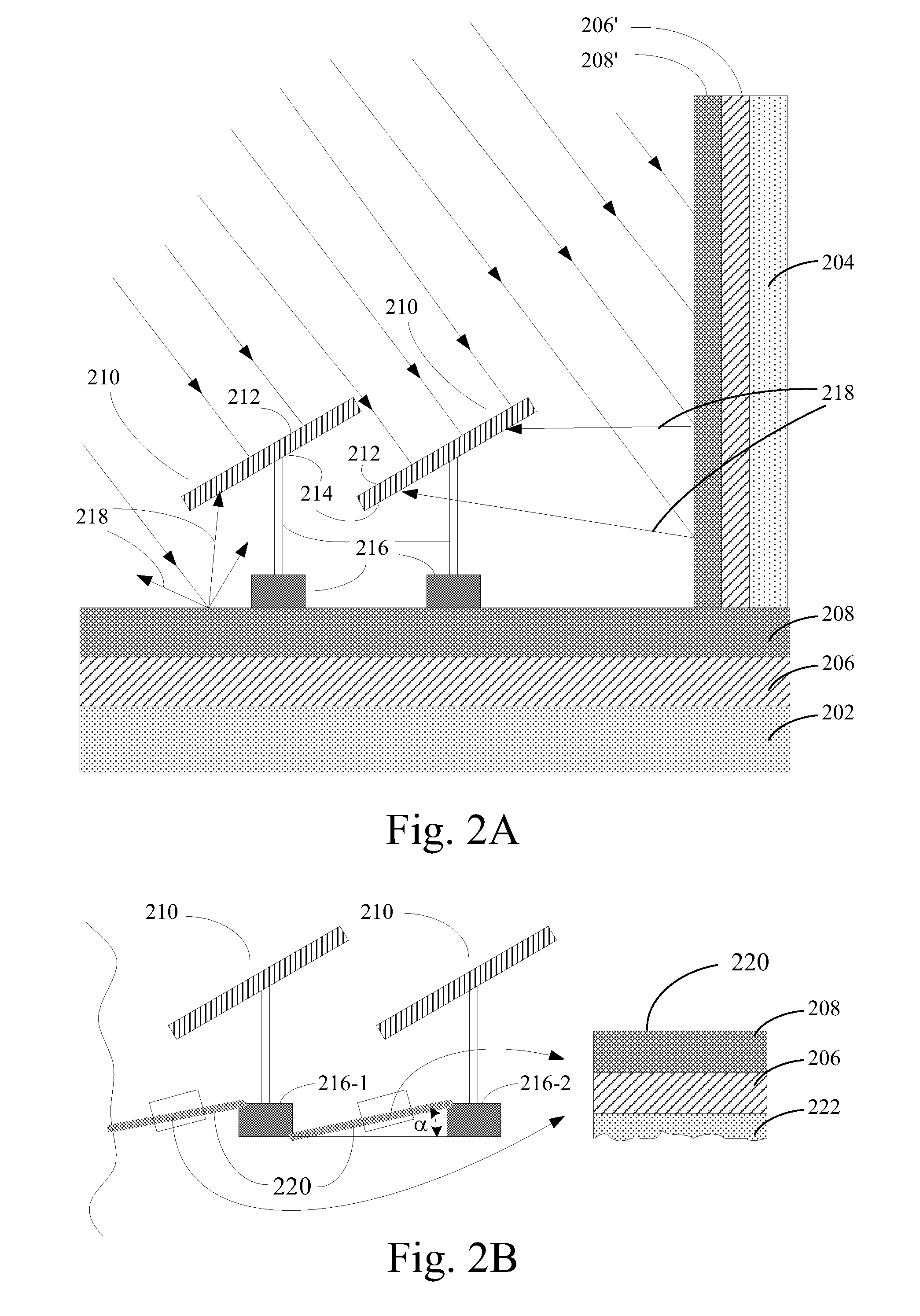

[0039]The present invention discloses systems and methods for improving existing photovoltaic cell assemblies that utilize albedo effects thereby improving their performance. As depicted in FIG. 2A, an albedo collector system in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com