Method for manufacturing light emitting apparatus, light emitting apparatus, and mounting base thereof

a technology of light emitting apparatus and mounting base, which is applied in the direction of manufacturing tools, lighting and heating apparatus, lighting support devices, etc., can solve the problems of generating cuttings, failure to illuminate, and problem occurrence, so as to avoid the application of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

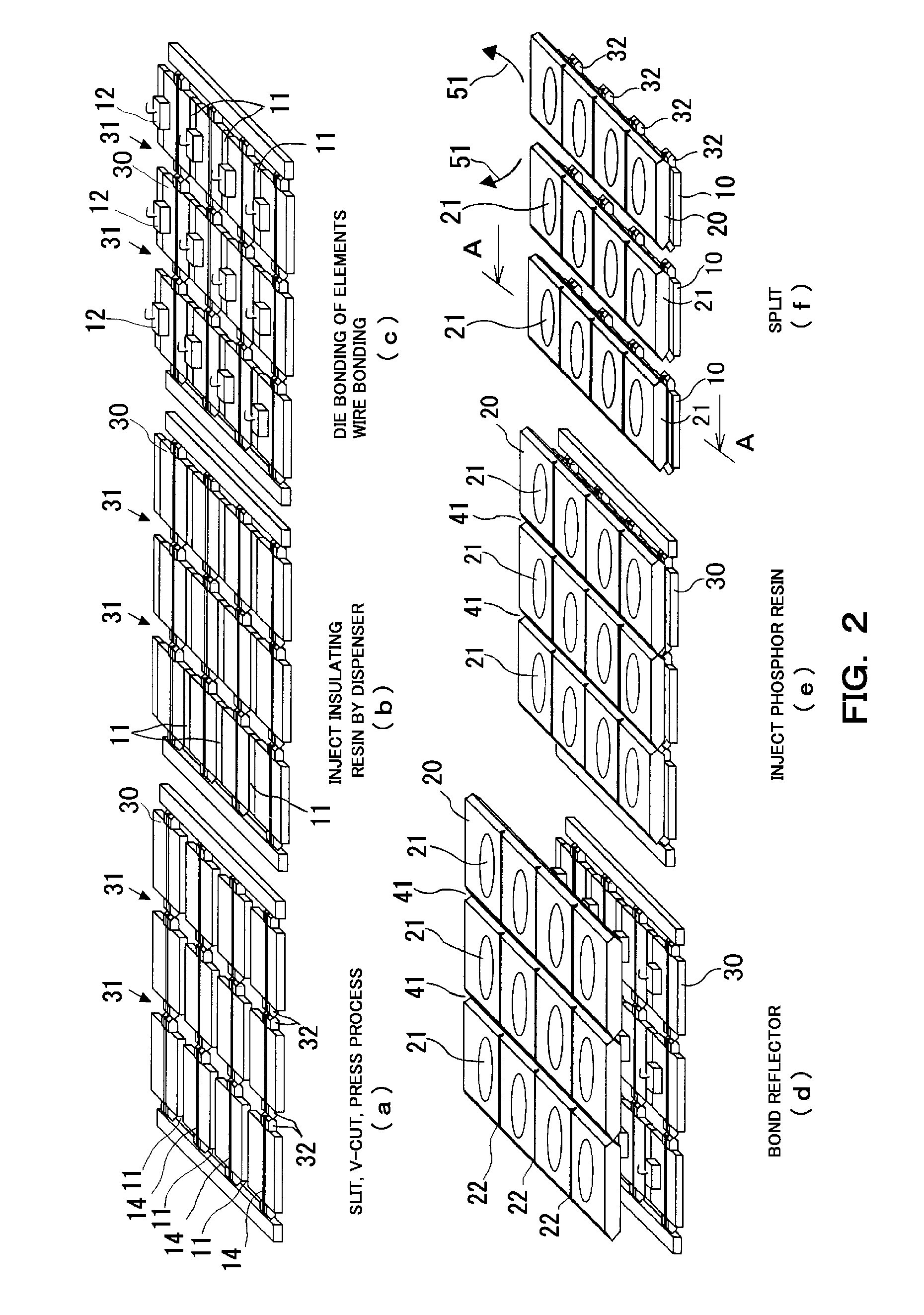

[0031]In the first embodiment, a method for manufacturing a line-shaped light emitting apparatus will be explained.

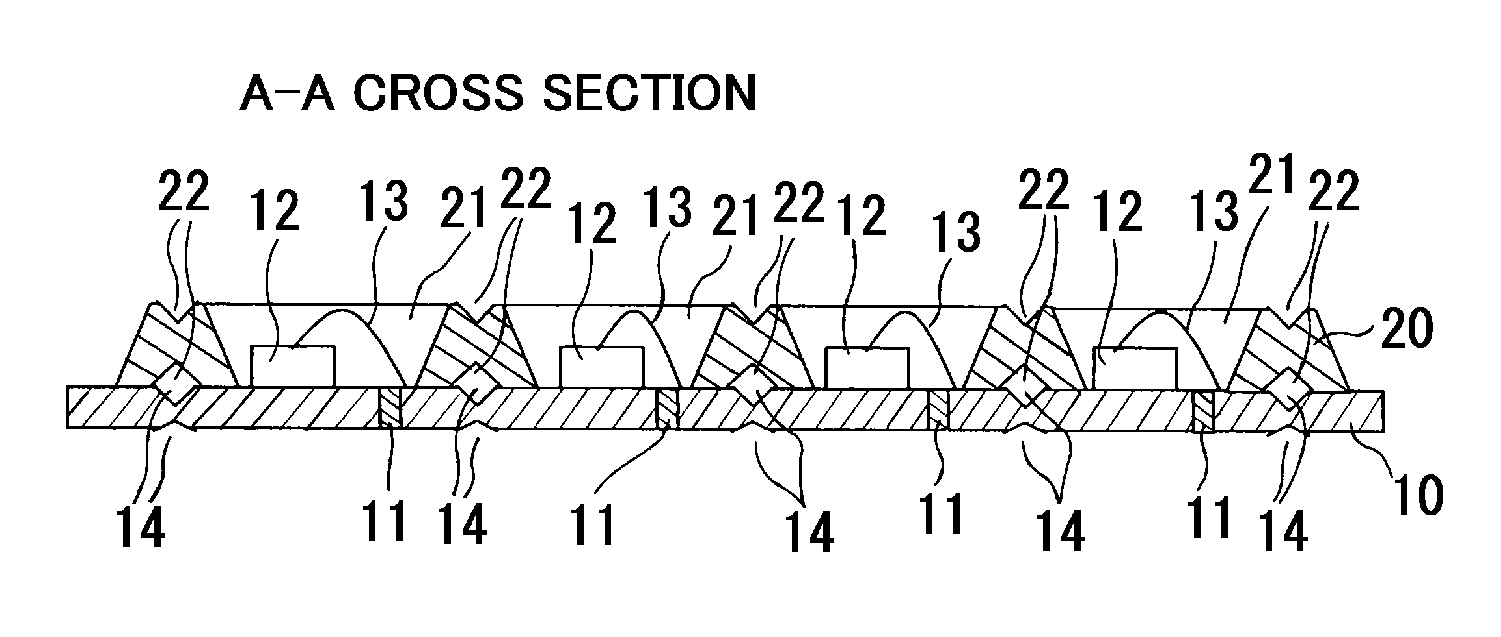

[0032]As illustrated by the sectional view of FIG. 1 and the perspective view of FIG. 2(f), the line-shaped light emitting apparatus incorporates a mounting plate 10 made of metal, four LED elements 12 mounted in a line in the longitudinal direction of the mounting plate 10, and a plate-like reflector 20 made of resin mounted in such a manner as superimposed on the mounting plate 10. The plate-like reflector 20 is provided with four apertures 21 each being a mortar shape and the reflector is mounted on the mounting plate 10 in such a manner that the LED elements 12 are positioned respectively in the apertures 21 at the center thereof.

[0033]As illustrated by the top view of the mounting plate 10 in FIG. 3, the mounting plate 10 made of metal is provided with four insulating slits 11 which are orthogonal to the longitudinal direction of the mounting plate 10, respectively...

second embodiment

[0058]Next, the second embodiment of the present invention will be explained.

[0059]The first embodiment is directed to a procedure that the insulating adhesive is injected into the insulating slit 11 by the dispensing method in the step shown in FIG. 2(b), and the adhesive agent is coated on the surface of the metal plate 30 in the step shown in FIG. 2(d), so as to bond the reflector 20 thereon. In the second embodiment, the step of FIG. 2(b) and the step of FIG. 2(d) are integrated to one step.

[0060]Specifically, as shown in FIG. 7(b), before the dispensing step, steps for die bonding of the LED element 12 and bonding of the wire 13 are performed. Thereafter, in the dispensing step, when the insulating adhesive is injected into the insulating slit 11 by a dispenser, injection volume is increased, thereby allowing the adhesive agent to overflow from the insulating slit 11 onto the top surface of the metal plate 30. Accordingly, as shown in FIG. 8, it is possible to form an adhesive ...

third embodiment

[0063]In the first embodiment, the LED element 12 is die-bonded by using the adhesive resin, but the method of die bonding is not limited to such usage of the adhesive agent. In the third embodiment, there will be explained a case where die bonding is performed by eutectic bonding.

[0064]When eutectic solder (e.g., AuSn alloy) is used for the die bonding, it is necessary to heat the solder up to 180° C. or higher so as to melt the solder. Therefore, if the die bonding is performed after injecting the insulating adhesive agent into the insulating slit 11, there is a possibility that the heat may cause deterioration (e.g., discoloration or exfoliation of resin). In the third embodiment, die bonding of the LED element 12 is performed before the dispensing step. Firstly, in the step as shown in FIG. 9(b), the die bonding is performed by using the eutectic solder, and thereafter in the step as shown in FIG. 9(c) the insulating adhesive agent is injected into the insulating slit 11. Subseq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com