Nitrated non-cyclic N-Alkane scaffolds with differentiated-mean combustive equivalencies as high energy density fuel improvers

a cyclic n-alkane and scaffold technology, applied in the direction of fuel additives, liquid carbonaceous fuels, fuels, etc., can solve the problems of limited utility of biodiesel, high cloud point inherently, fuels used in diesel engines, etc., to achieve the combustive efficiency of the desired blended fuel, increase the energy density, and increase the effect of fuel combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

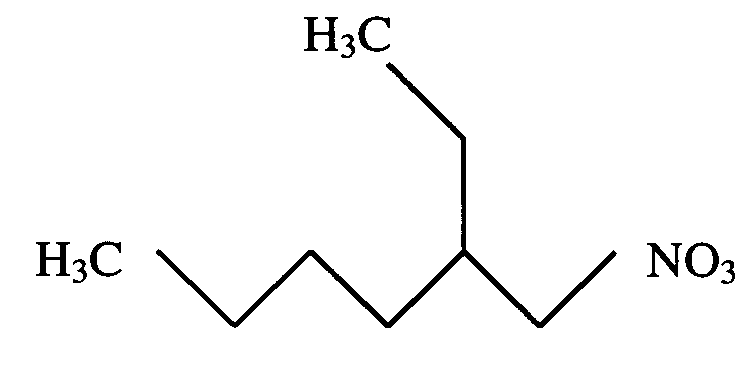

[0074]A multi-functional combustively dense, or high-energy-density fuel additive (HEDFA), which in the preferred embodiment is to be mixed with a ratio of one part of fuel additive to 1,000 parts of fuel, but which can be mixed in a range between one part of additive to 5,000 parts of base fuel, to one part of additive to 50 parts of base fuel to create a desired blended fuel, is comprised of one or more members of a molecular family having an n-alkane base scaffolding to which at least one trioxynitrate (NO3) is attached (xTONnA, for x-TriOxyNitro-n-Alkane), which in the preferred embodiment is 2-Ethylhexyl nitrate, having the following basic structure:

[0075]and the molecular linear formula CH3(CH2)(C2H5)CH2ONO2, though the n-alkane itself can be any non-cyclic and non-aromatic, non-alkene, linear or saturated hydrocarbon of the formula CnH2n+2; with said molecules comprising at least the plurality of the additive. These formulations produce the unexpected result of creating a fue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cetane number | aaaaa | aaaaa |

| Cetane number | aaaaa | aaaaa |

| Cetane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com