Ball catcher apparatus for use in fracturing of formations surrounding horizontal oil and gas wells, and method for using same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

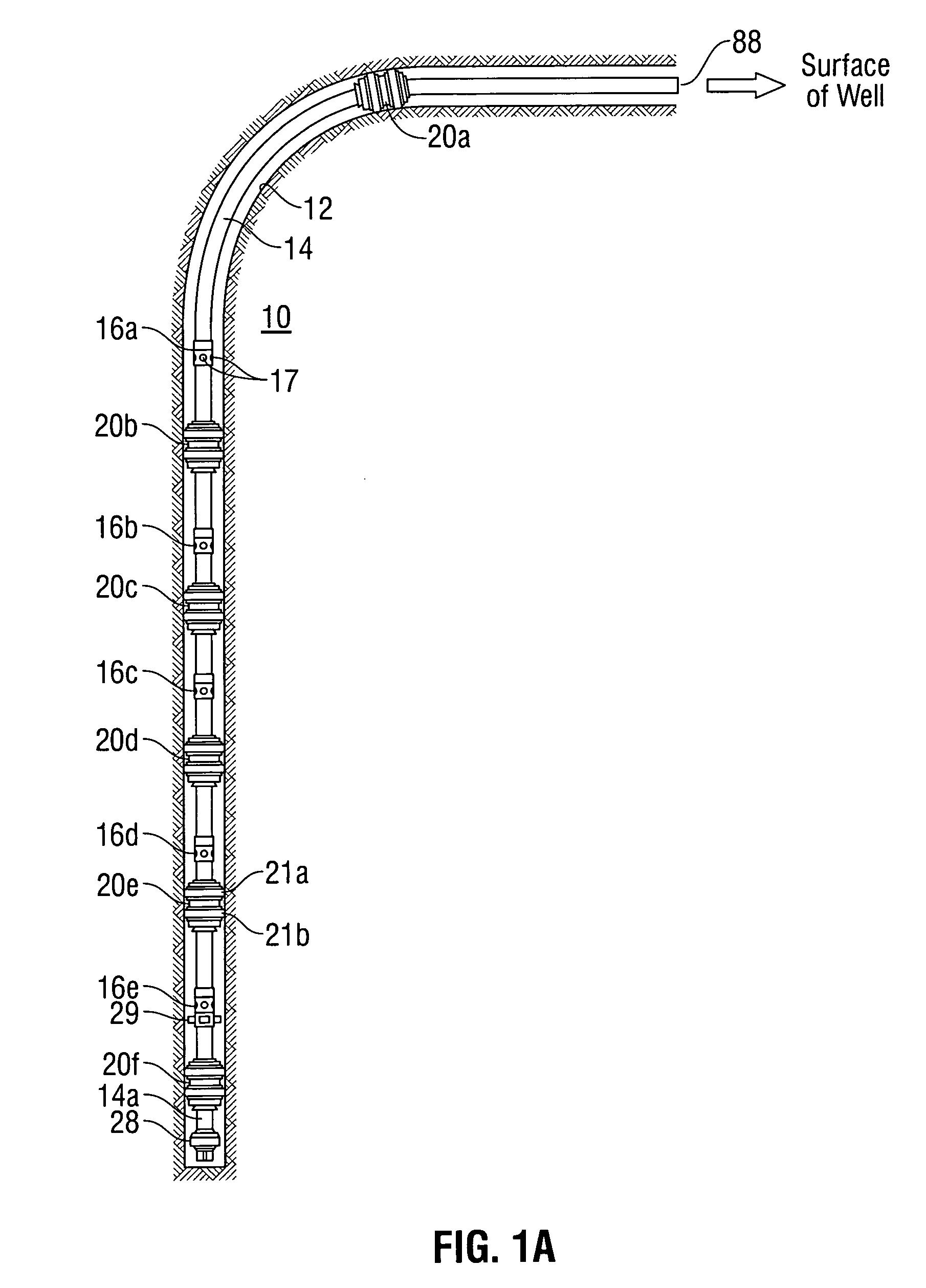

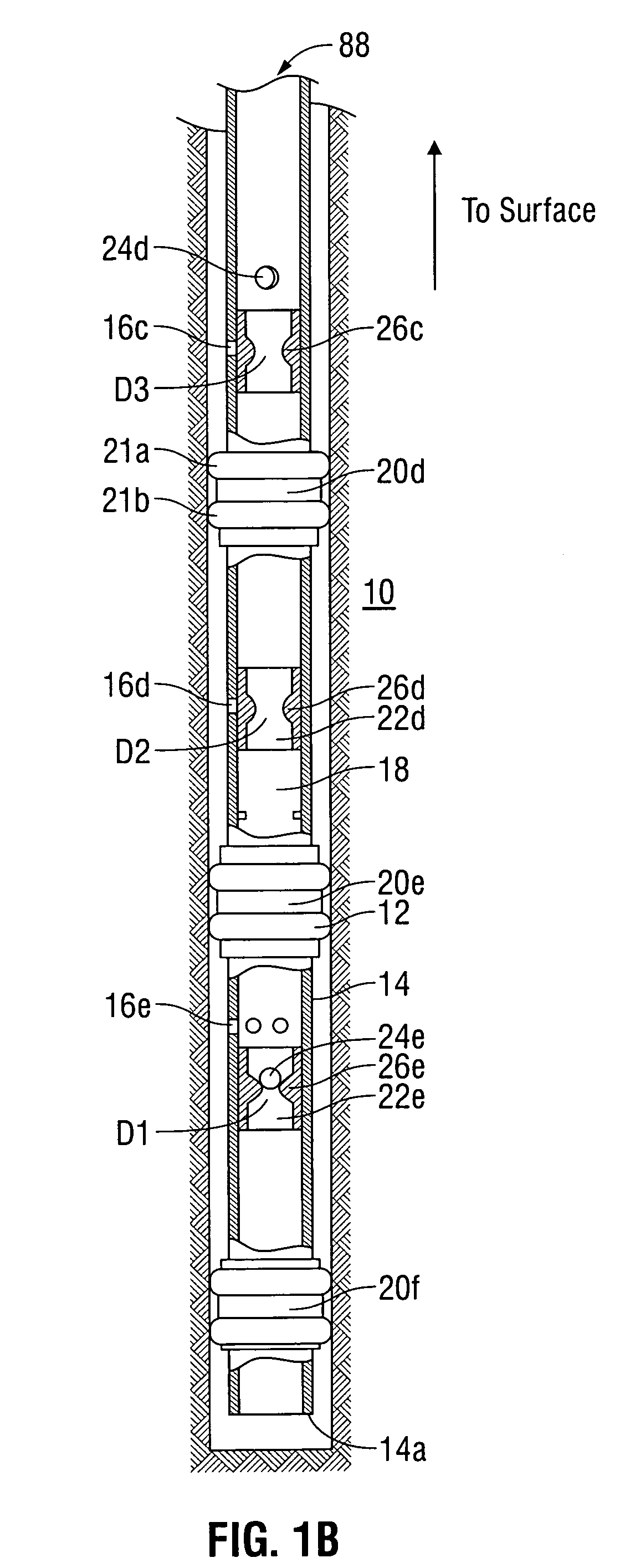

[0022]FIGS. 1a, 1b and 1c illustrate portions of the technology identified herein above relating to the well-known Packer Plus system for selectively fracturing formations surrounding horizontal oil and gas wells.

[0023]Referring further to FIGS. 1a, 1b and 1c, a wellbore fluid treatment assembly is shown, which can be used to effect fluid treatment of a formation 10 through a wellbore 12. The wellbore assembly includes a tubing string 14 having a lower end 14a and an upper end extending to surface (not shown). Tubing string 14 includes a plurality of spaced apart ported intervals 16a to 16e each including a plurality of ports 17 opened through the tubing string wall to permit access between the tubing string inner bore 18 and the wellbore.

[0024]A packer 20a is mounted between the upper-most ported interval 16a and the surface and further packers 20b to 20e are mounted between each pair of adjacent ported intervals. In the illustrated embodiment, a packer 20f is also mounted below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com