Melamine foam pads for motorized floor cleaning machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Whereas melamine resin is disclosed as a binder of fibrous materials and abrasive particles in rotary floor machine pads, for example those described in U.S. Pat. No. 5,685,042 to Demetriades, a melamine foam rotary floor pad has not been used, other than when augmented by surrounding support and scouring brush structure as in Japanese published patent application JP 2008-99768(A) to Morishita. Although melamine eraser pads have shown short lifetimes, experiments have indicated that the current invention, which supports the melamine foam and brings it into contact with the floor at a consistent pressure, displayed unexpected results and unexpected longevity.

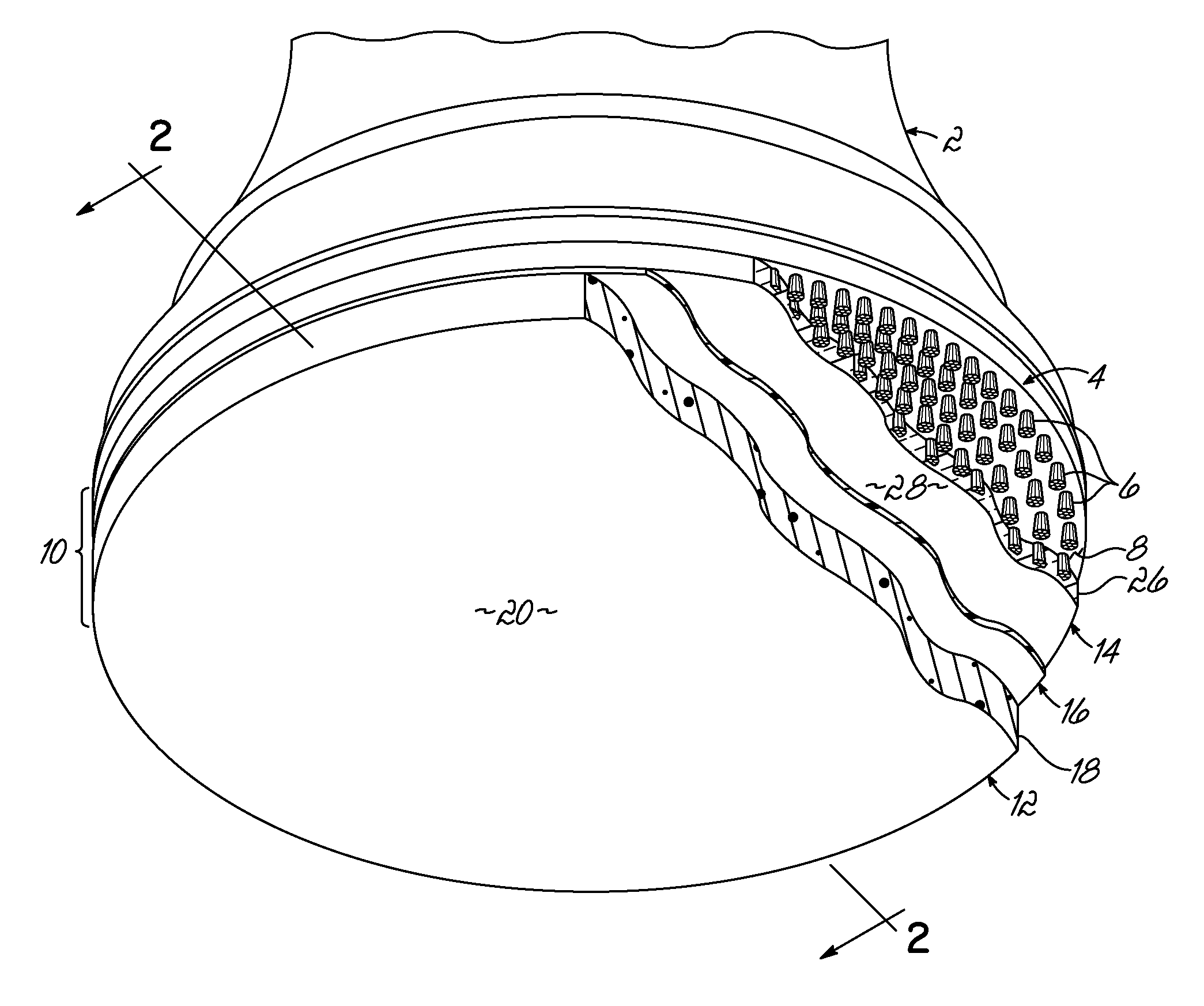

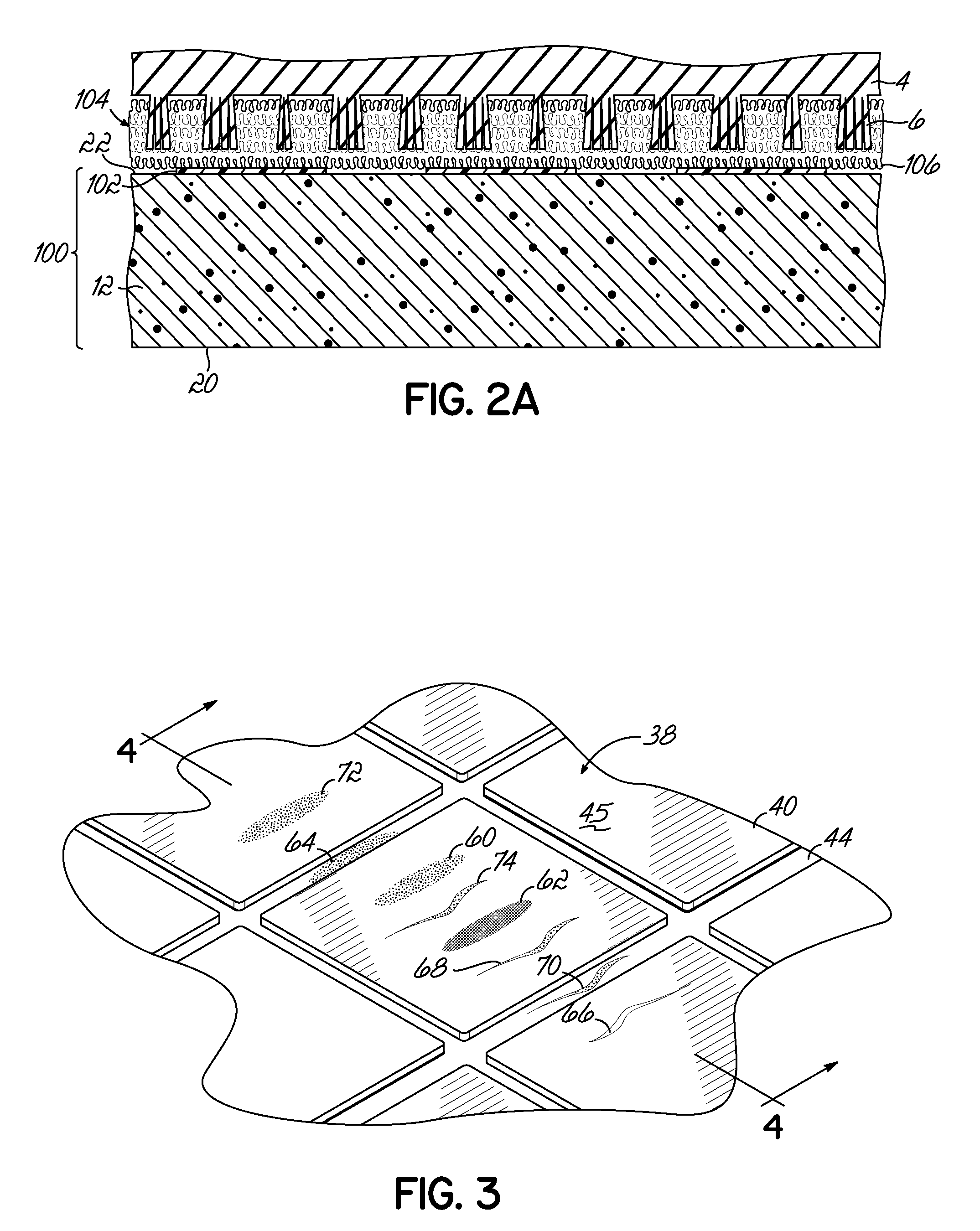

[0035]FIGS. 1 and 2 illustrate the deck of a rotary motorized floor machine 2 having a pad driver 4 with bristles 6 extending from bottom surface 8 that drives a melamine foam floor pad 10. Typical rotational speeds for machine 4 having pads 10 of the invention attached thereto are in the range of from about 150 to about 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com