Tyre for vehicle wheels having improved tread pattern

a technology for vehicle wheels and treads, which is applied in the direction of vehicle components, transportation and packaging, non-skid devices, etc., can solve the problems of reduced tread stiffness, substantial noise and blockage of mobility, and rapid tread wear ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

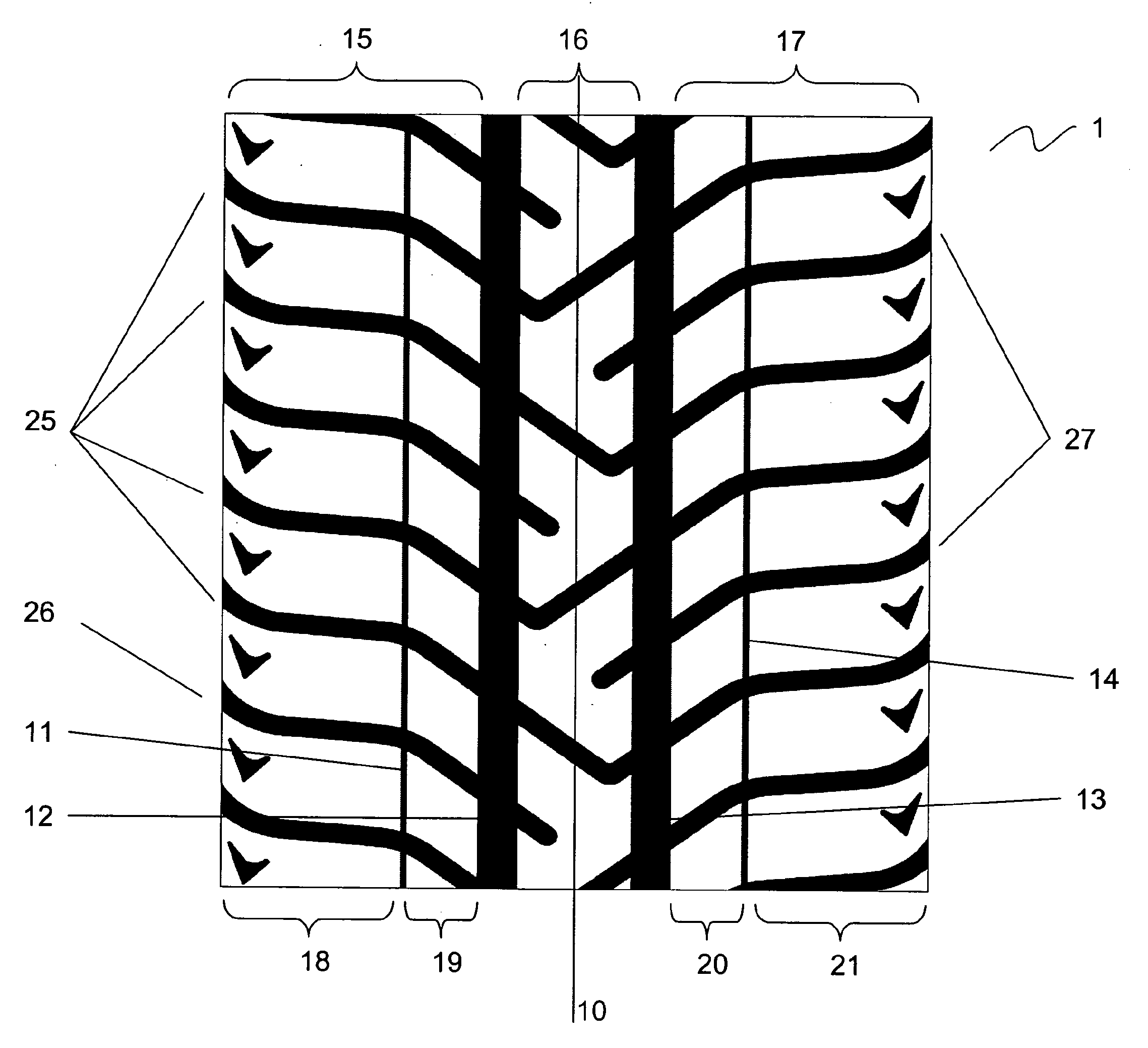

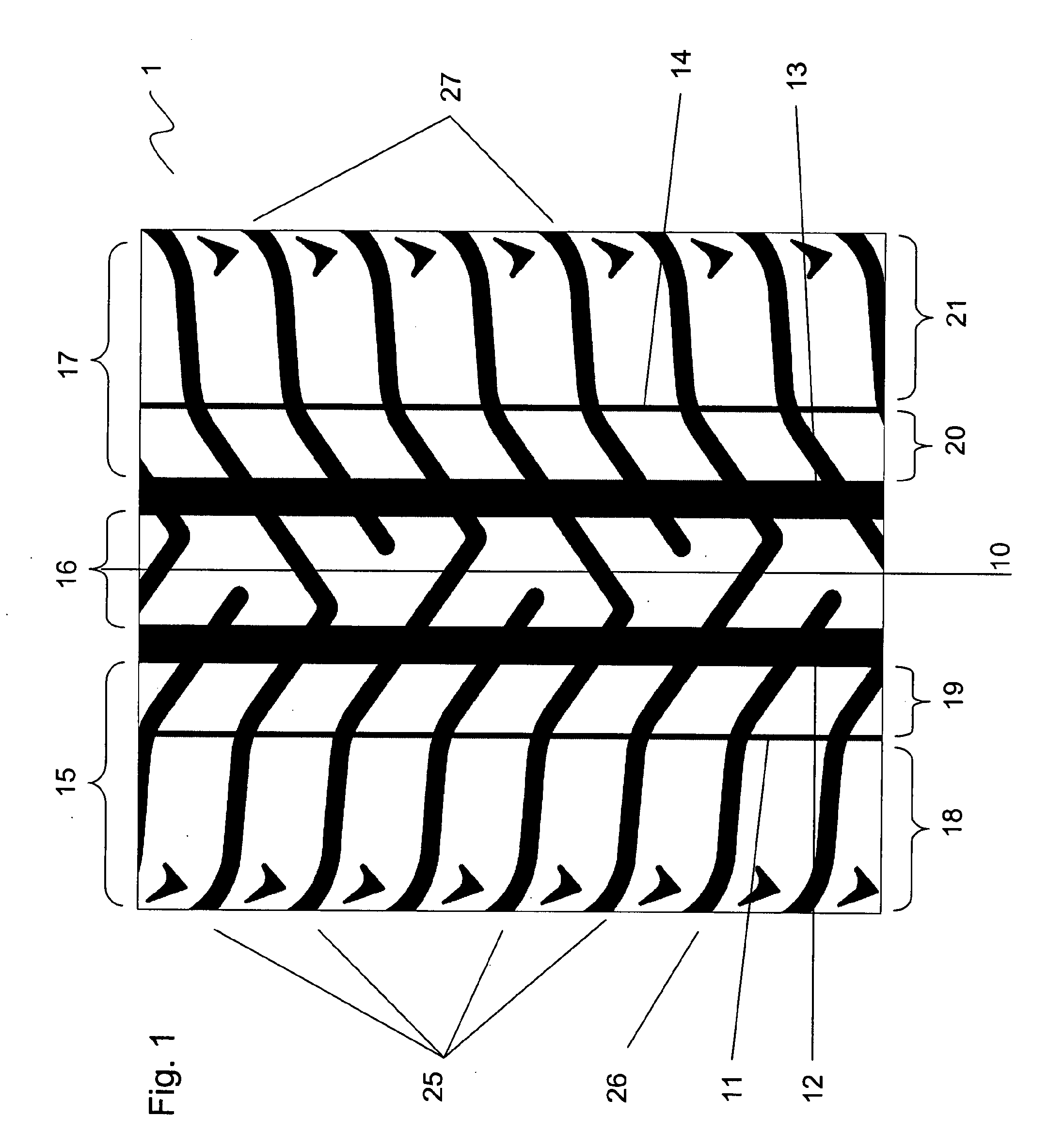

[0042]FIG. 1 is a plan view of the tyre tread 1 in accordance with a preferred embodiment of the present invention.

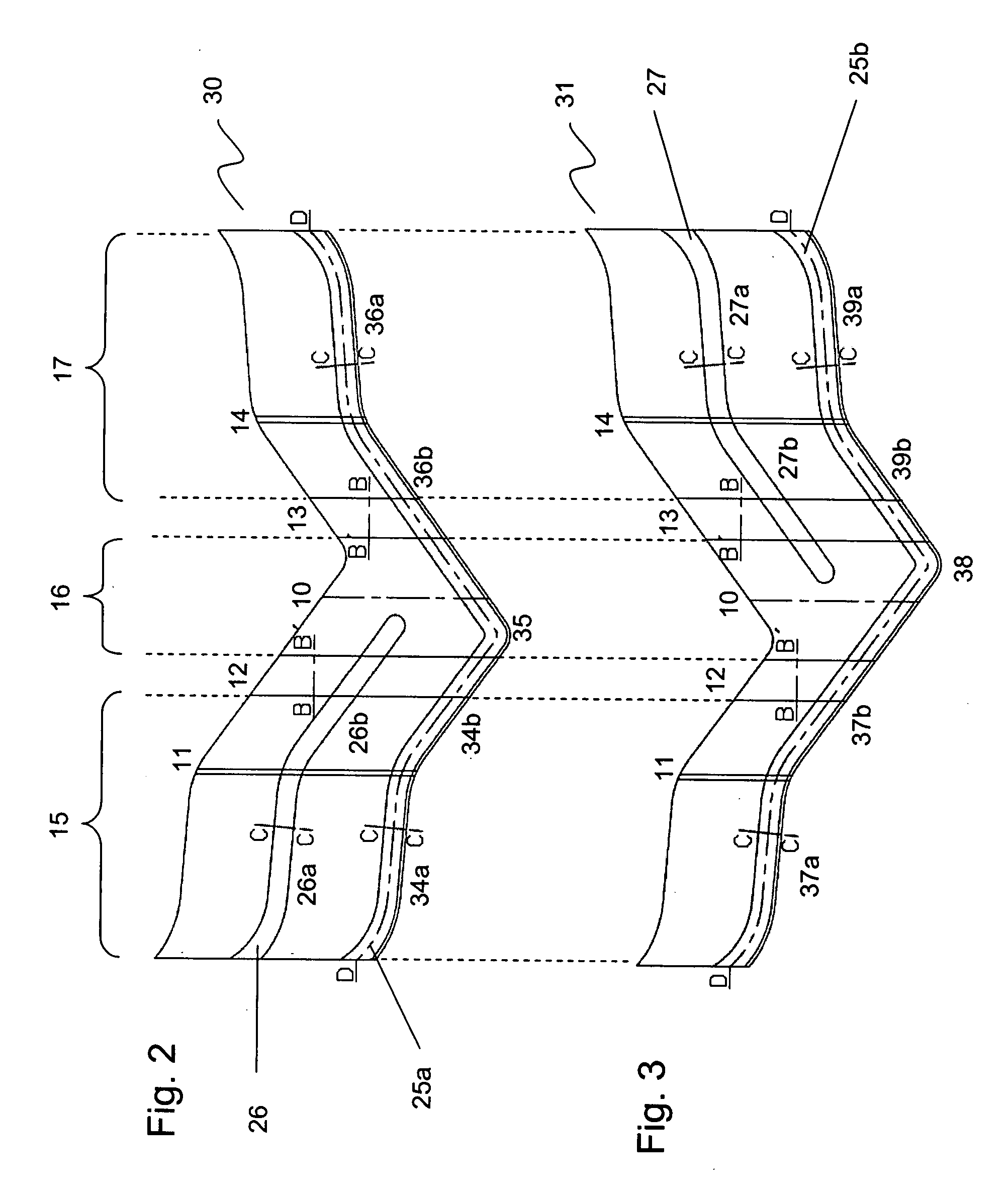

[0043]The tread 1 comprises two internal circumferential grooves 12 and 13, and, according to a preferred embodiment, two external circumferential grooves 11 and 14. The circumferential grooves 12 and 13 separate a tread central region 16 from two tread shoulder regions 15 and 17 located on the left and on the right of the equatorial plane 10, respectively. The circumferential grooves 11 and 14 divide in two portions each shoulder regions 15 and 17, respectively. The circumferential groove 11 divides the left shoulder regions 15 in an external shoulder portion 18 and an internal shoulder portion 19. The circumferential groove 14 divides the right shoulder regions 17 in an internal shoulder portion 20 and an external shoulder portion 21.

[0044]The tread 1 comprises a plurality of asymmetric transverse grooves 25 having a substantially “V” shape, which substantially extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com