Variable conductance heat pipe

a heat pipe and conductance technology, applied in semiconductor lasers, lighting and heating equipment, instruments, etc., can solve the problems of wasteful electric power use, long waiting time, and inconvenience for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

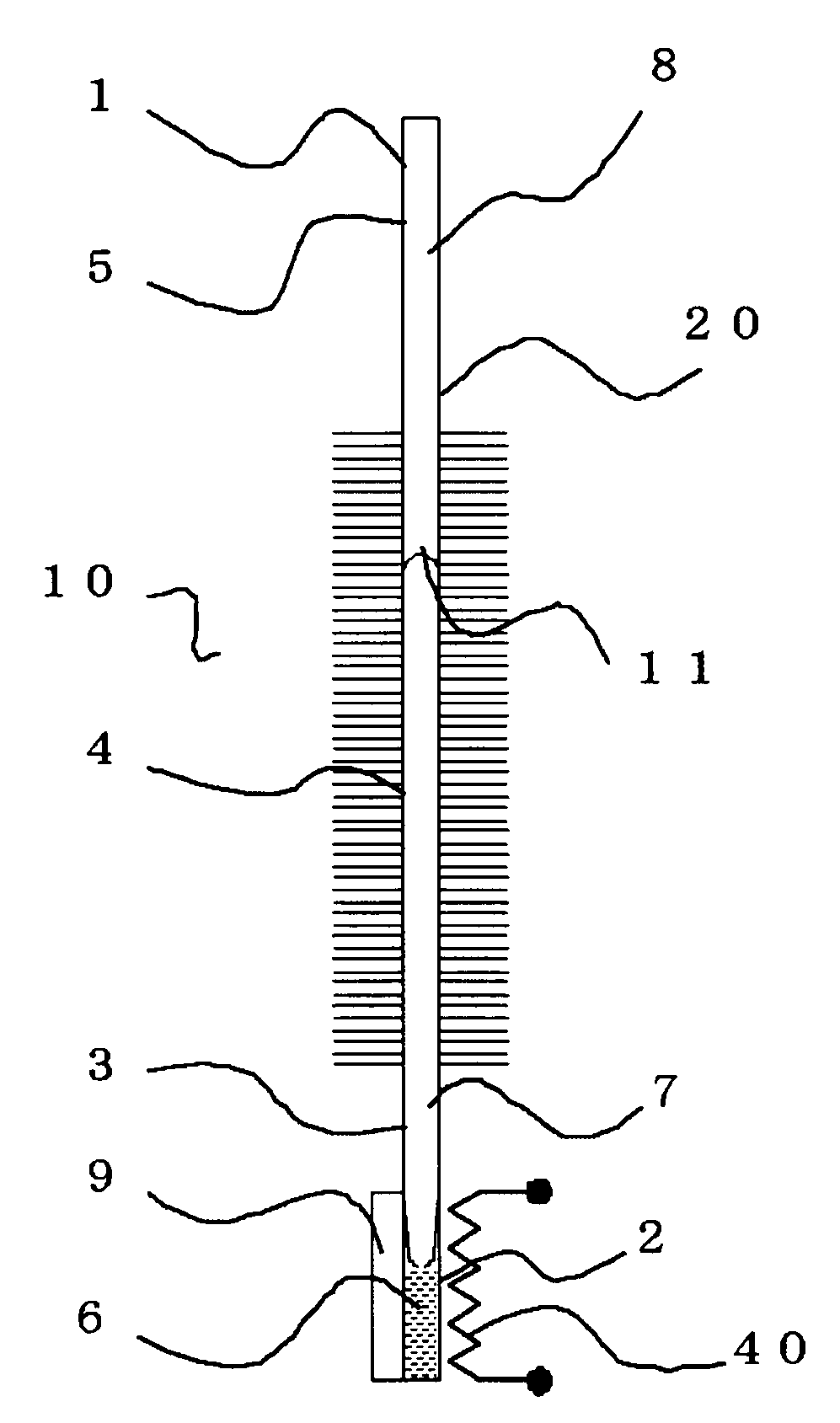

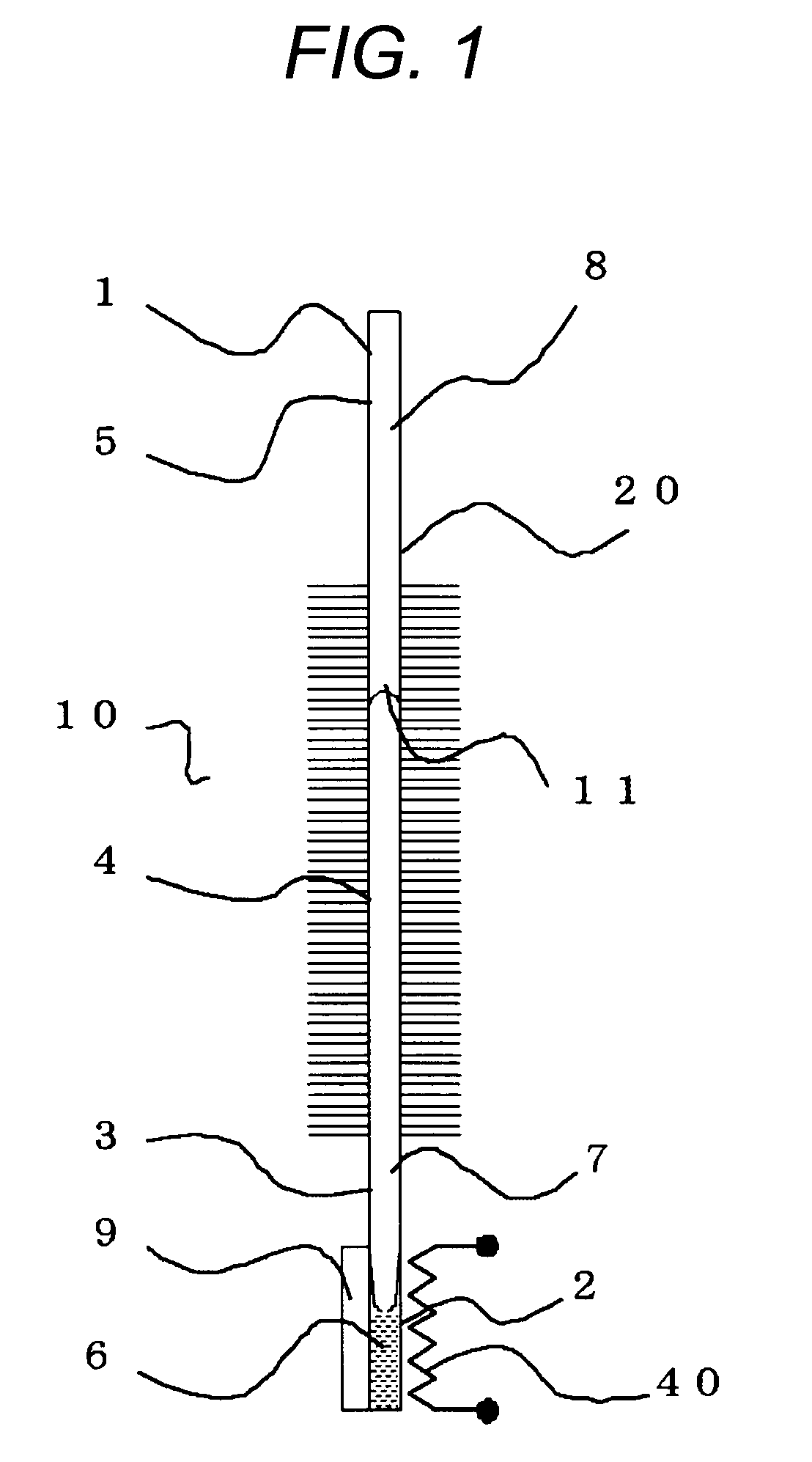

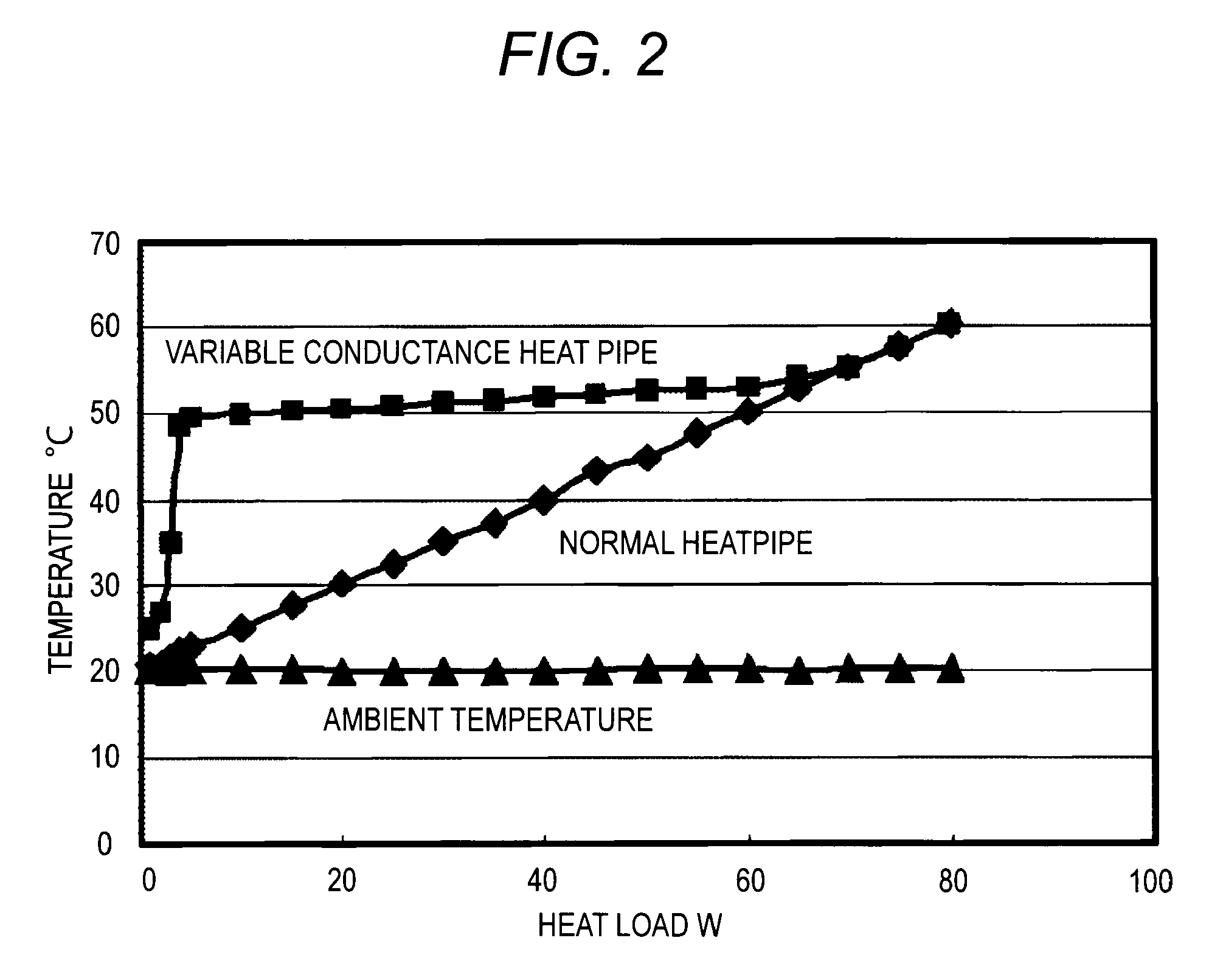

[0017]FIG. 1 is a sectional view showing a variable conductance heat pipe according to Embodiment 1 of the invention. As shown in FIG. 1, from one end portion, a variable conductance heat pipe 20 includes a sealed container 1 are a heat receiving portion 2 (an evaporating portion), a heat insulating portion 3 (a transporting portion), a heat radiating portion 4 (a condensing portion) and a noncondensable gas reservoir portion 5. A working fluid (a liquid 6 and vapor 7 thereof) and a noncondensable gas 8 are sealed in an interior of the sealed container 1. A heater 40 and an element to be cooled 9 are provided to the heat receiving portion 2.

[0018]Next, the operation of the variable conductance heat pipe of the Embodiment 1 will be described. When the element to be cooled 9 is activated to operate to obtain a desired function of the element to be cooled 9, heat is generated in an interior of the element to be cooled 9, whereby the temperature of the element to be cooled 9 is raised. ...

embodiment 2

[0033]FIG. 3 is a diagram showing the configuration of Embodiment 2 of the invention. While in Embodiment 1, the temperature of the heat receiving portion 2 can be set to an arbitrary temperature with less energy, when a main part 12 (of which the temperature needs to be controlled) in the element to be cooled 9 lies away from the heat receiving portion 2 (when a thermally interposed material 13 is interposed therebetween), even in Embodiment 1, there is generated a difference in temperature which corresponds to a thermal resistance of the thermally interposed material 13 is generated when the element to be cooled 9 is not in operation. Then, in Embodiment 2, by providing a heater 40 near a main part 12 in the element to be cooled 9, a difference in temperature which is generated by a heat input from the heater 40 and the thermal resistance of a thermally interposed material 13 can be compensated for, thereby making it possible to reduce a difference in temperature between when the ...

embodiment 3

[0036]FIG. 4 is a diagram showing the configuration of Embodiment 3 of the invention. In this configuration, a fan 14 is provided for forcing a cooling fluid to flow through a heat radiating portion 4 of a variable conductance heat pipe 20, an element to be cooled 9 is provided within a temperature sensor 15, and the fan 14 and the heater 40 are controlled with respect to outputs thereof by the temperature sensor 15 and a control circuit 16, so as to provide an optimum temperature control. The fan 14 may be a pump which causes the cooling fluid to flow to the heat radiating portion. Namely, the fan 14 may take any form, as long as it remains a cooler for cooling the heat radiating portion 4.

[0037]By adopting this configuration, the temperature of the element to be cooled 9 can be controlled through heating / cooling via the variable conductance heat pipe 20, whereby not only can a transition time to a set temperature and a waiting time of the user be shortened, but also the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com