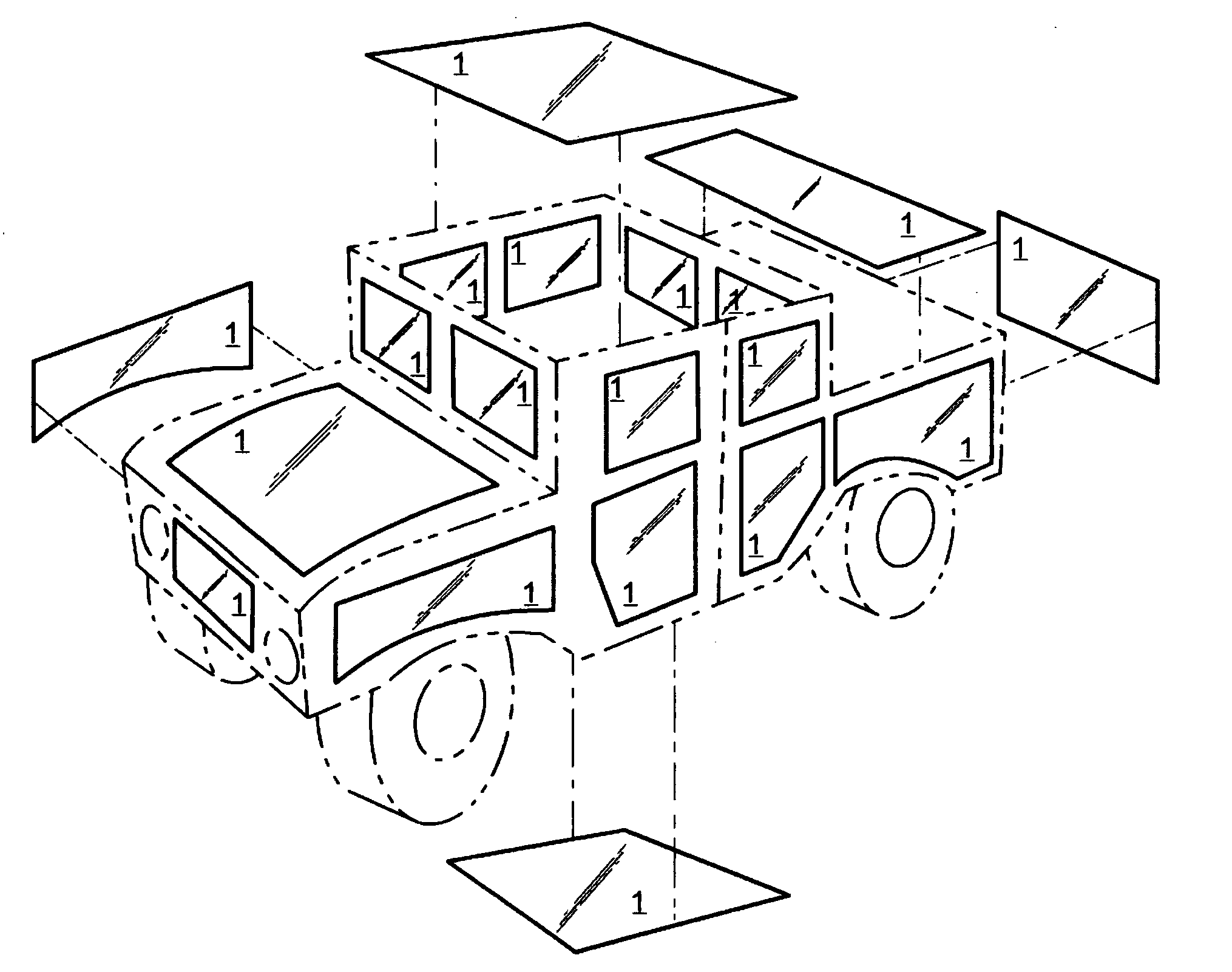

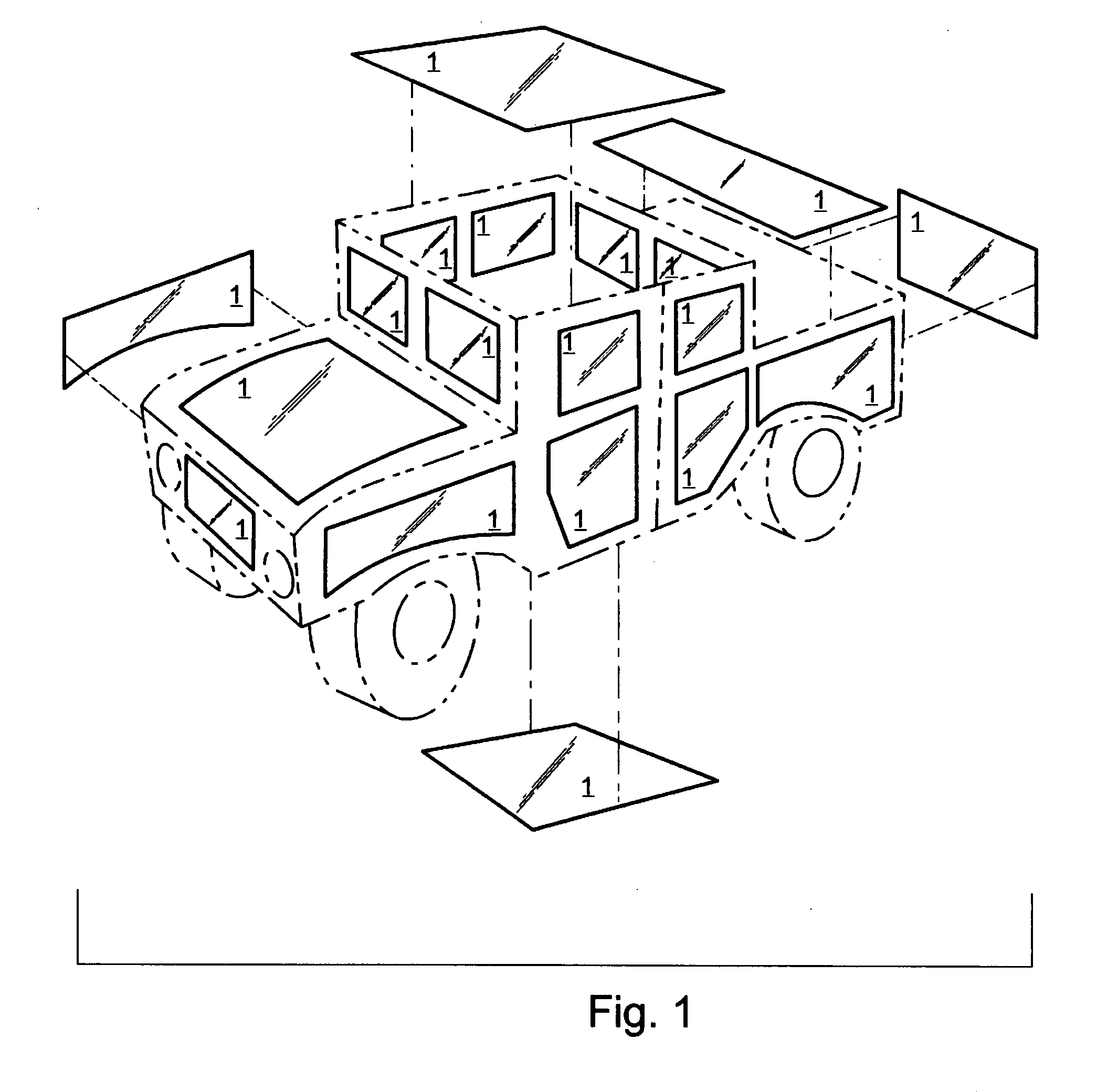

Articles, manufactures, and assemblies utilizing configured and sized plates comprised of penetration-proof laminated constructs formed of asymmetric composite materials

a technology of composite materials and configurations, applied in the direction of shields, protective equipments, armoured vehicles, etc., can solve the problems of real danger to life and limbs, the degree of jeopardy of the body and life of a living human or animal subject will vary,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example 1

Opaque Composite Material Blast Testing

[0121]The physical specifications of the opaque composite material being tested are provided by Table E1 below.

TABLE E1Layers ofCompositeLayerMaterialThicknessLayer MaterialsNumber 1.125 inchAR 500 Steel(high hardened)Number 2 .03 inchIonomer Resin (Surlyn ®)Number 3.125 inchOpaque Ceramic (98%pure aluminum silicate)Number 4 .03 inchIonomer Resin (Surlyn ®)Number 5.375 inchAramid Fiber(Rigid Kevlar ®)Total: 5.56 inch, or 14.3 mmTotal weight per squarelayers × 3for eachfoot: 10.03 lbs.stacksindividual stack

[0122]In order to test the capability of one embodiment of the present invention to withstand projectile and fragment penetration, a 12″×12″ opaque composite material test, sample having the dimensions described in Table E1 was installed in a metal frame at a height of approximately 5 feet. The sample was then subjected to six consecutive 7.62×39×AP steel core shots from an AK 47 rifle, followed by being further subjected to the metal shrapnel...

experimental example 2

Transparent Composite Material Blast Testing

[0125]Physical specifications of transparent composite material tested are provided by Table E3.

TABLE E3Layers ofCompositeLayerMaterialThicknessLayer MaterialsNumber 1 0.5 inchAnnealed glassNumber 2 0.06 inchSentryGlas Plus ®Number 30.375 inchAnnealed glassNumber 4 0.05 inchPolyurethaneNumber 50.375 inchPolycarbonateTotal: 51.36 inch, or 34.54 mmTotal weight per squarelayers × 3each forfoot: 14.33 lbs.stacksindividual stack

[0126]In order to test the capability of one embodiment of the present invention to withstand projectile and fragment penetration, a 12″×12″ opaque composite material test sample having the dimensions described in Table E3 was installed in a metal frame at a height of approximately 5 feet. The sample was then subjected to three consecutive 7.62×39×AP steel core shots from an AK 47 rifle, followed by being further subjected to the metal shrapnel fragments from a detonation blast of a 155 mm shell placed at the distance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com