Non-magentic access floor system for use in electronic imaging rooms

a technology of electronic imaging and access flooring, which is applied in the direction of flooring, roofs, ceilings, etc., can solve the problems of not efficiently cooling equipment, affecting the operation of emi machines and their output, and requiring cooling equipment, etc., to achieve the effect of elimination of metal on metal conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

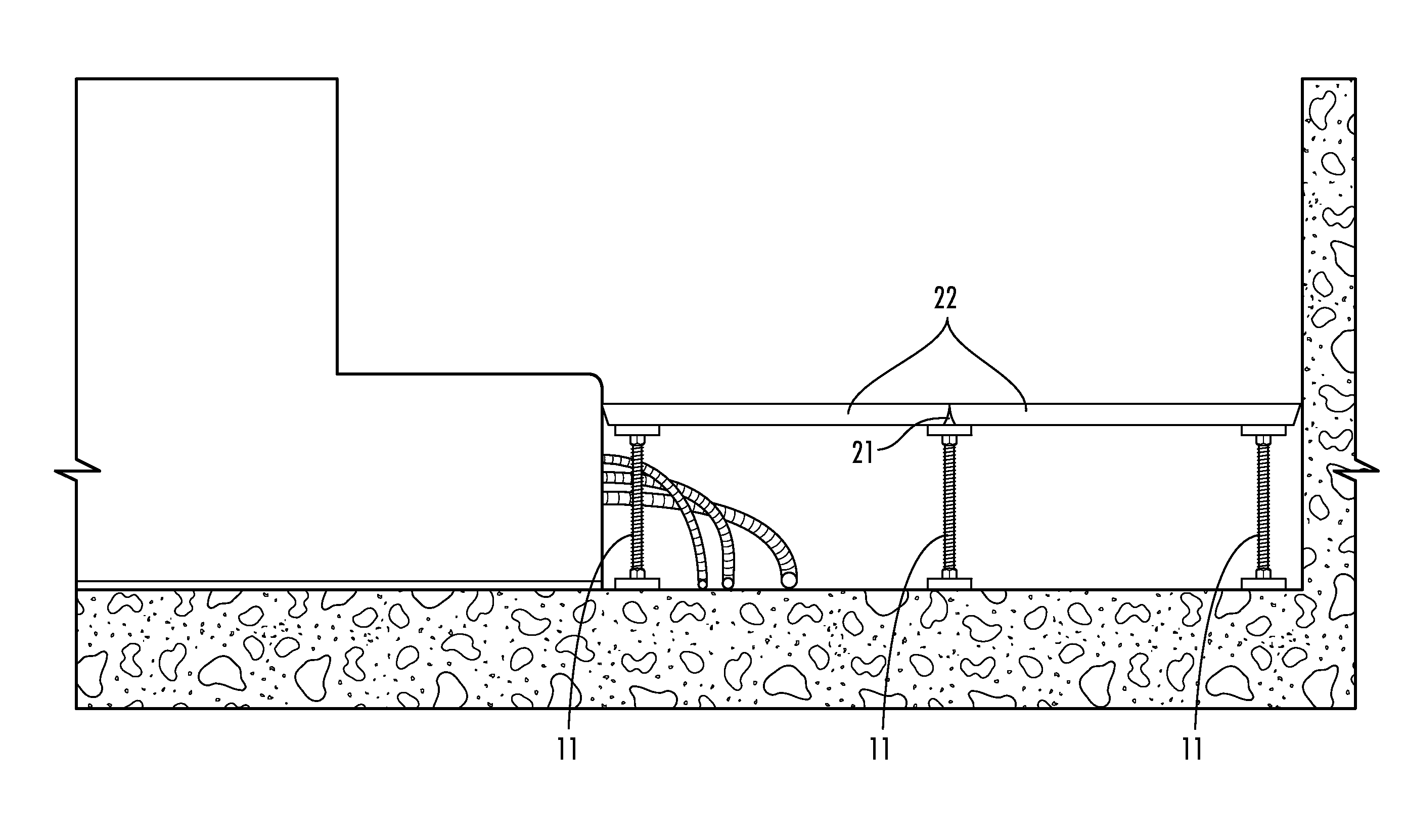

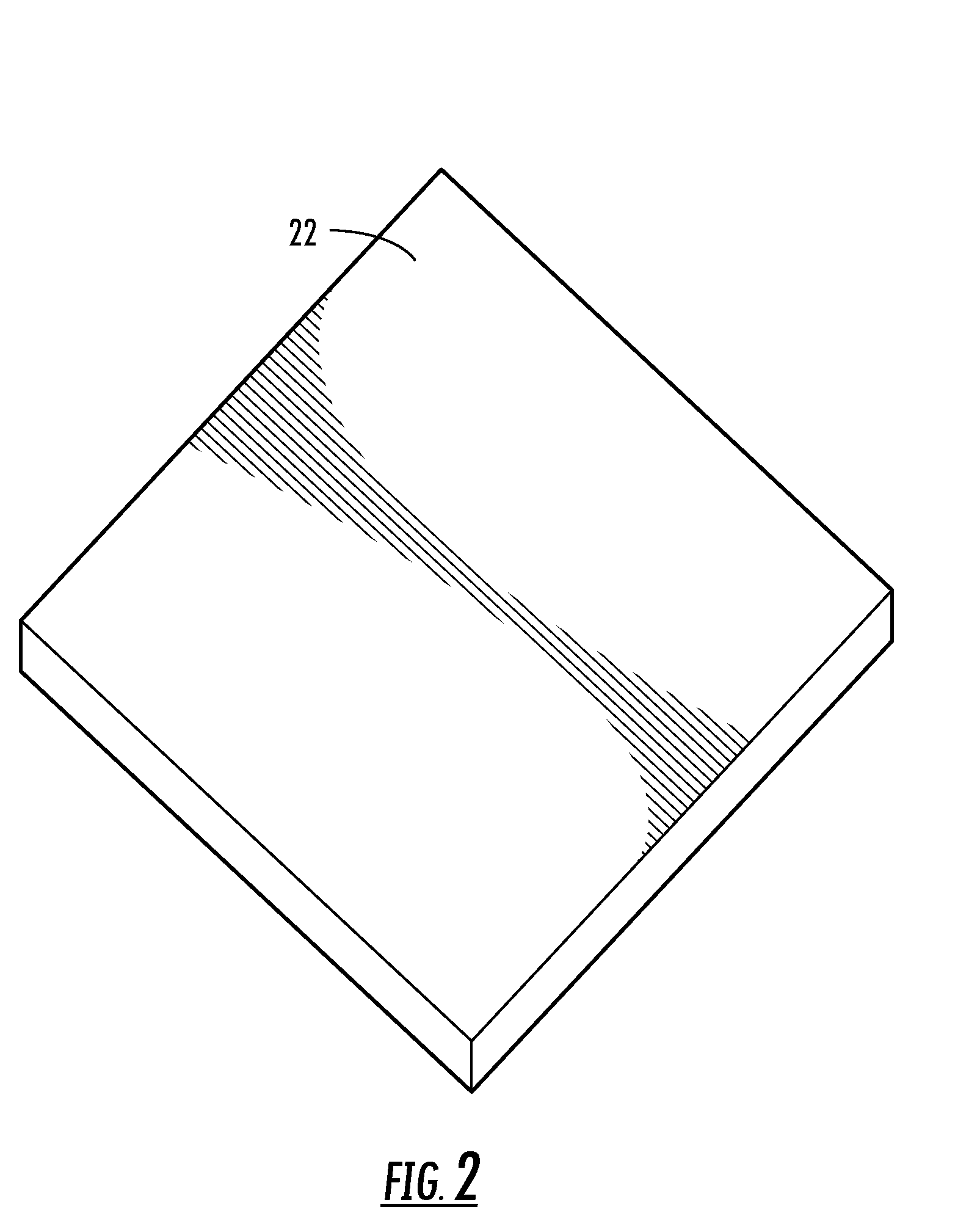

[0019]Now referring to the drawings, one embodiment of the access floor system of the present invention is shown and generally illustrated in the figures. As can be seen in the most general terms, an access floor system is provided for installation over a subfloor. The access floor system includes a pedestal assembly that is configured and arranged to be affixed to the subfloor and a floor panel formed from non-metallic materials that is supported in spaced relation above the subfloor by a plurality of said pedestal assemblies.

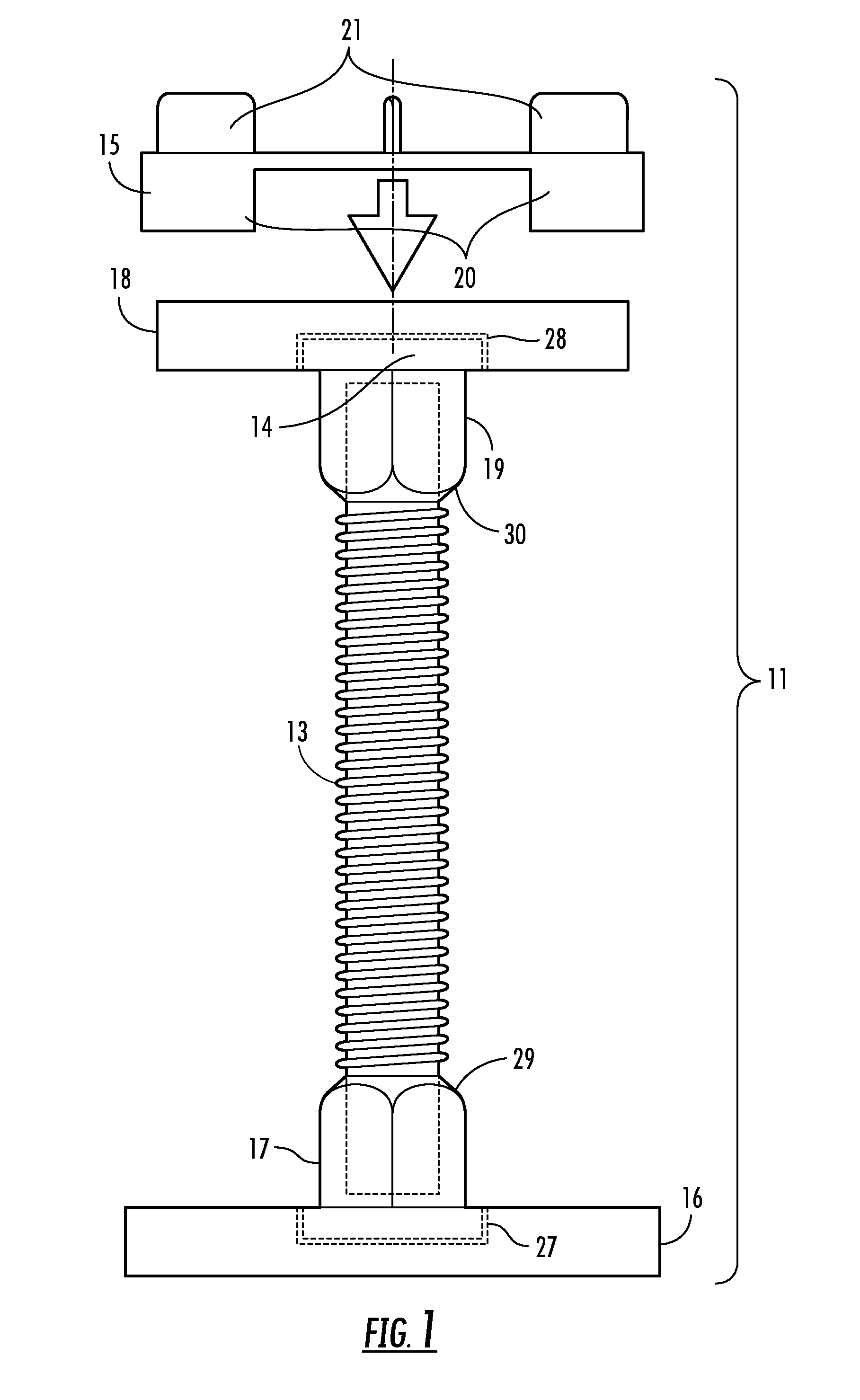

[0020]Turning now to FIG. 1, the pedestal assembly 11 is shown in detail. The pedestal assembly includes a polymer pedestal base 16 having a recess 27 in a top surface thereof a polymer pedestal head 18 having a recess 28 in a bottom surface thereof and a rod support 13 having a first end 29 configured to be received and retained in said recess 27 in the pedestal base 16 and a second end 30 configured to be received and retained in the recess 28 in said pedest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field | aaaaa | aaaaa |

| Metallic bond | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com