Method for producing packaged drink

a technology for packaging drinks and drinks, applied in the direction of packaging goods, liquid handling, transportation and packaging, etc., can solve the problems of high cost of containers, and rapid loss of taste and flavor, so as to increase the efficiency and speed of production lines, reduce container costs, and simplify equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

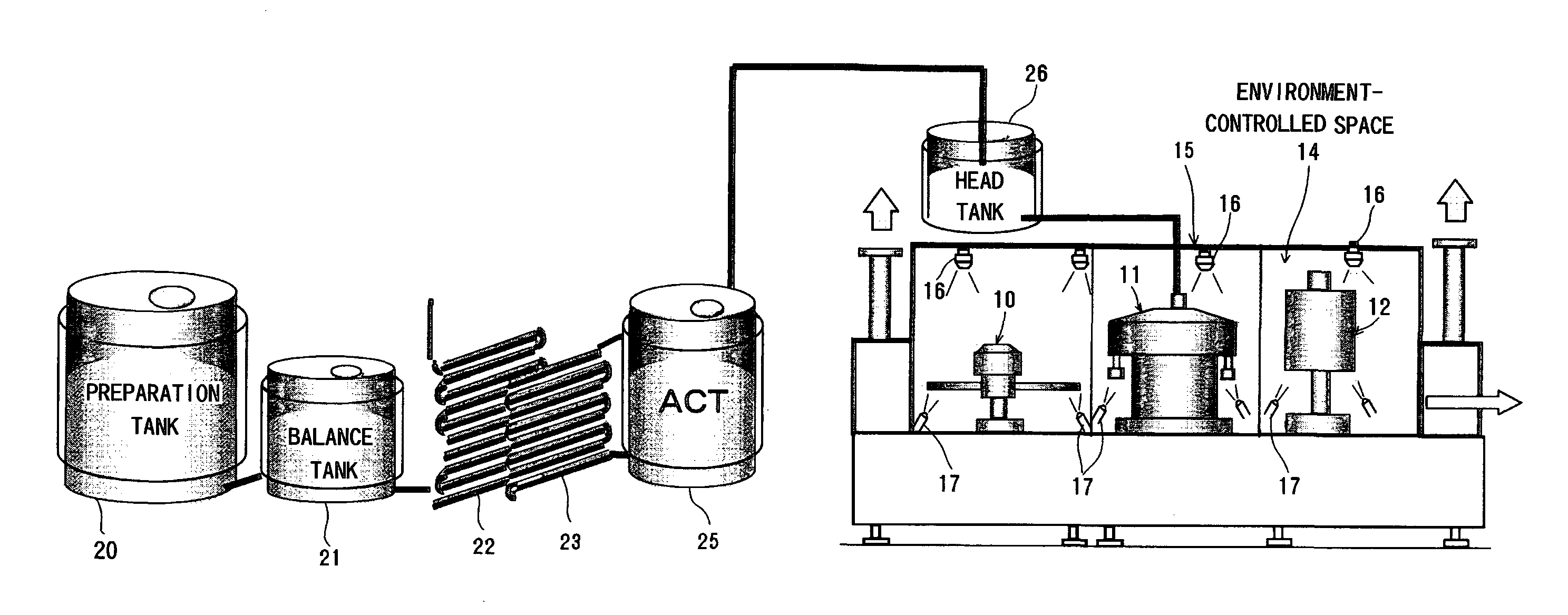

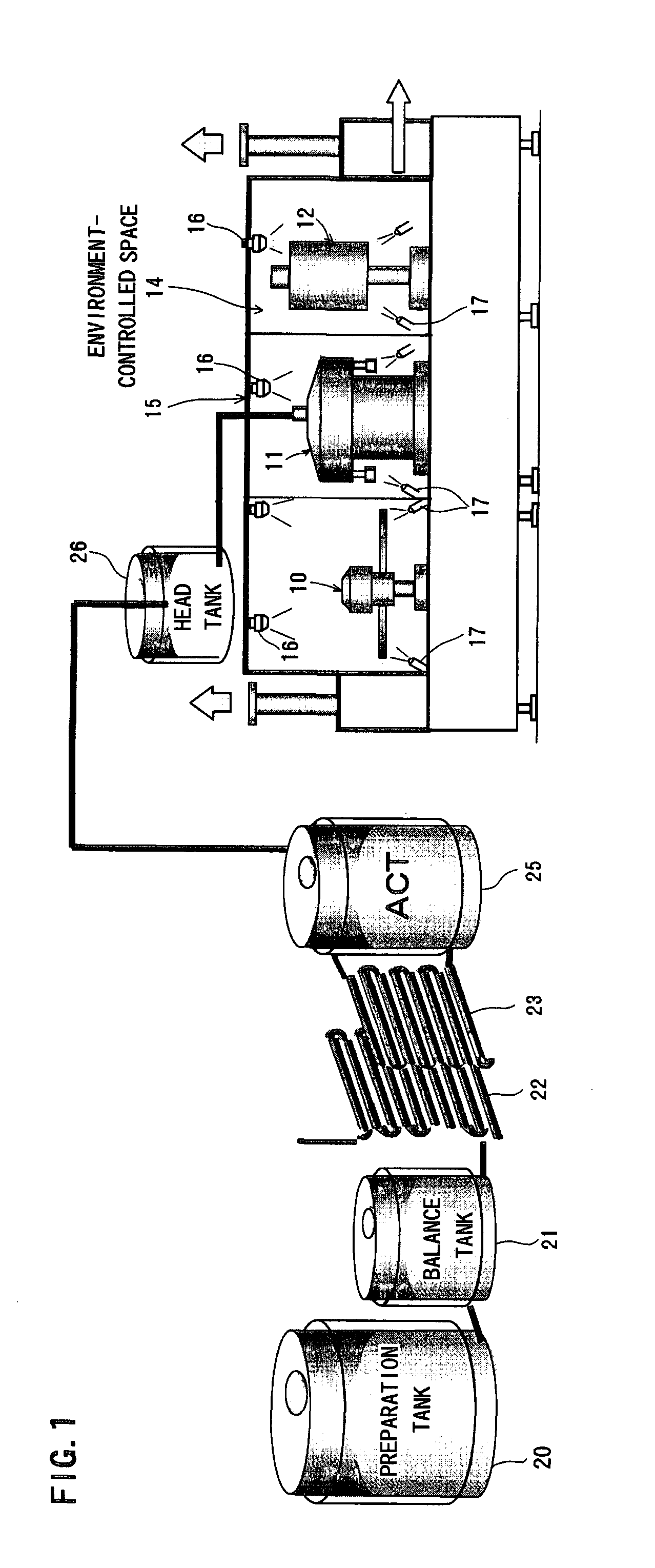

Method used

Image

Examples

example 1

[0078]A green tea drink (pH 5.9, catechin content 52 mg %) was produced using the above-described equipment and producing method, employing PET bottles having a 2 L capacity.

[0079]Specifically, a green tea drink having been thermally sterilized at high temperature for a short time, at 135° C. over 30 seconds, followed by rapid cooling to room temperature, was stored in a storage tank kept at a positive pressure with sterile gas and having been sterilized and washed beforehand to a sterilization value equal to or greater than the sterilization value of the content. Thereafter, the drink was pressure-fed to a head tank with sterile gas, and was then supplied to a filling machine, where the drink was filled into bottles having been thermally sterilized and washed beforehand with hot water at 90° C. for 3 seconds, within a controlled space. The drink was then sealed with caps sterilized and washed beforehand. The liquid path from the quick cooling device to the filling machine is a clos...

example 2

[0085]A 100% orange juice acidic drink (pH 3.61) was produced using the above-described equipment and producing method, employing PET bottles having a 1.5 L capacity.

[0086]Specifically, the acidic drink having been thermally sterilized at high temperature for a short time, at 94.5 to 96° C. over 30 seconds, followed by rapid cooling to room temperature (31° C. to 32° C. in the present example), was stored in a storage tank kept at a positive pressure with sterile gas and having been sterilized and washed beforehand to a sterilization value equal to or greater than the sterilization value of the content. Thereafter, the acidic drink was bottled into bottles thermally sterilized and washed with hot water at 90° C. for 3 seconds, in accordance with the same method of Example 1. The filling temperature was herein 30° C. As in Example 1, immediately after production of the acidic drink was over, the pH value, hue and vitamin C of the orange juice drink thus obtained were measured immedia...

example 3

[0107]A green tea drink (pH 5.9, catechin content 52 mg %) was produced using the above-described equipment and producing method, employing PET bottles having a 2 L capacity.

[0108]Specifically, the controlled space in which containers are washed, filled and sealed was sterilized beforehand at 40° C. for 10 minutes using a peracetic acid chemical agent (trade name: Toyo Active) at a concentration of 2000 ppm, followed by washing with hot water at 90° C. An antiseptic effect of 6 D or higher against spore-forming bacteria such as B. subtilis, B. coagulans was observed. Then, a green tea drink having been thermally sterilized at high temperature for a short time, at 135° C. over 30 seconds, followed by rapid cooling to room temperature, was stored in a storage tank kept at a positive pressure with sterile gas and having been sterilized and washed beforehand to a sterilization value equal to or greater than the sterilization value of the content. Thereafter, the drink was pressure-fed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com