Heat storage materials and methods of manufacturing the heat storage materials

a technology of heat storage materials and heat storage materials, which is applied in the direction of regenerative heat exchangers, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of troublesome operation, increased organic acid and peroxide, and degraded performance of adsorption materials, so as to absorb and dissipate latent heat in response to temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

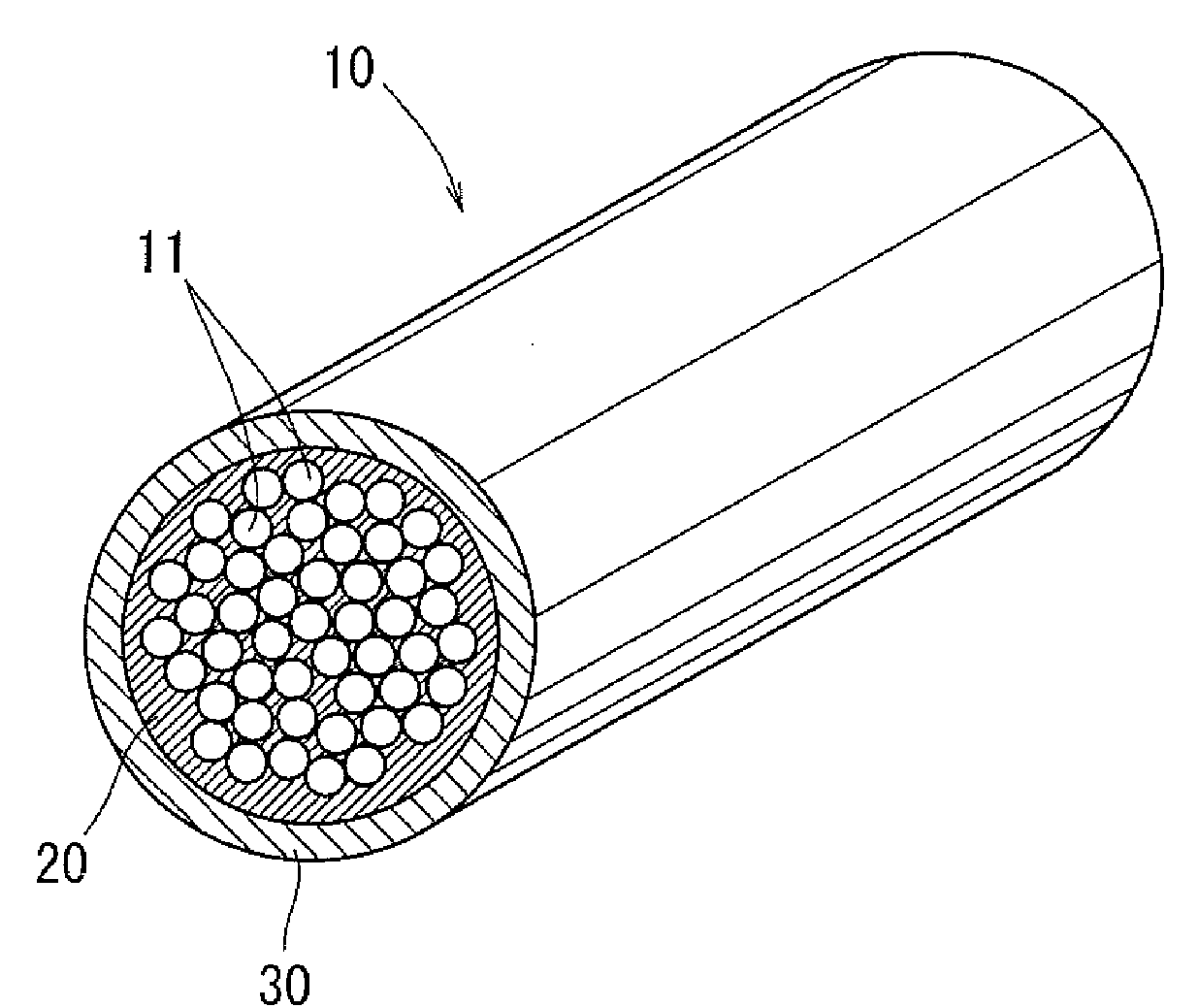

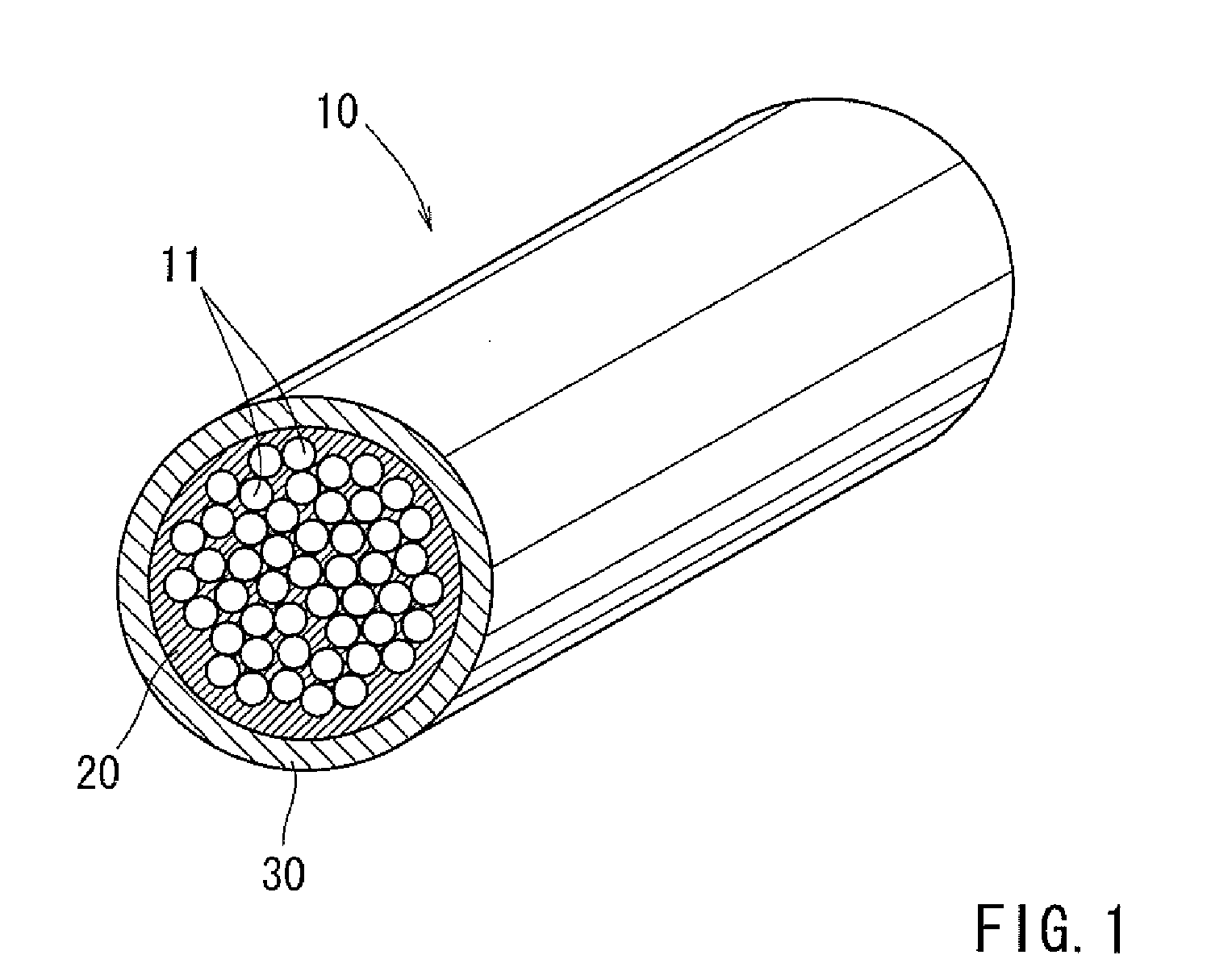

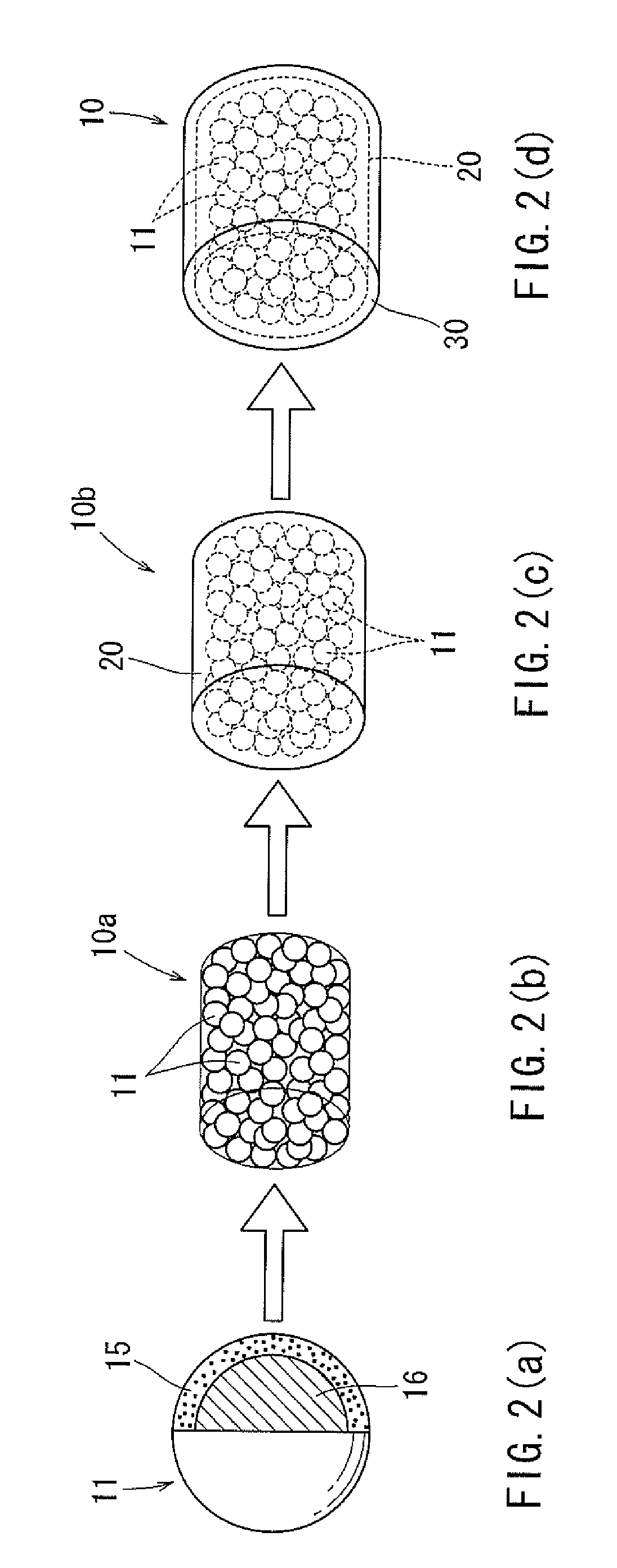

Image

Examples

example

[0039]Second unfinished heat storage granules covered by underlying layers were obtained by the same process as in Comparative Example 2, and the second unfinished heat storage granules were then immersed into a water solution of surfactant in the concentration of 500 ml / l, and were ultrasonically washed for five minutes at 75° C. The heat storage granules were then again washed by water, immersed into a plating bath containing nickel in the concentration of 155 ml / l, and electrolessly plated for 25 minutes at 90° C. As a result, cover layers having a thickness of 5 μm were formed on the second heat storage granules.

(Immersion Tests)

[0040]Immersion tests were conducted to the heat storage granules of Example and Comparative Examples 1 and 2 by immersing the heat storage materials into ethanol-containing gasoline filled within pressure resistant bottles. During the immersion tests, the pressure resistant bottles were sealingly closed and were immersed into an oil vessel that contains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com