Optical head device and optical information reproducing device

a head device and optical information technology, applied in the direction of data recording, disposition/mounting of heads, instruments, etc., can solve the problems of deterioration of recording/reproducing characteristics, avoid adverse effects of recording/reproducing characteristics, and improve the signal to noise ratio of rf signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

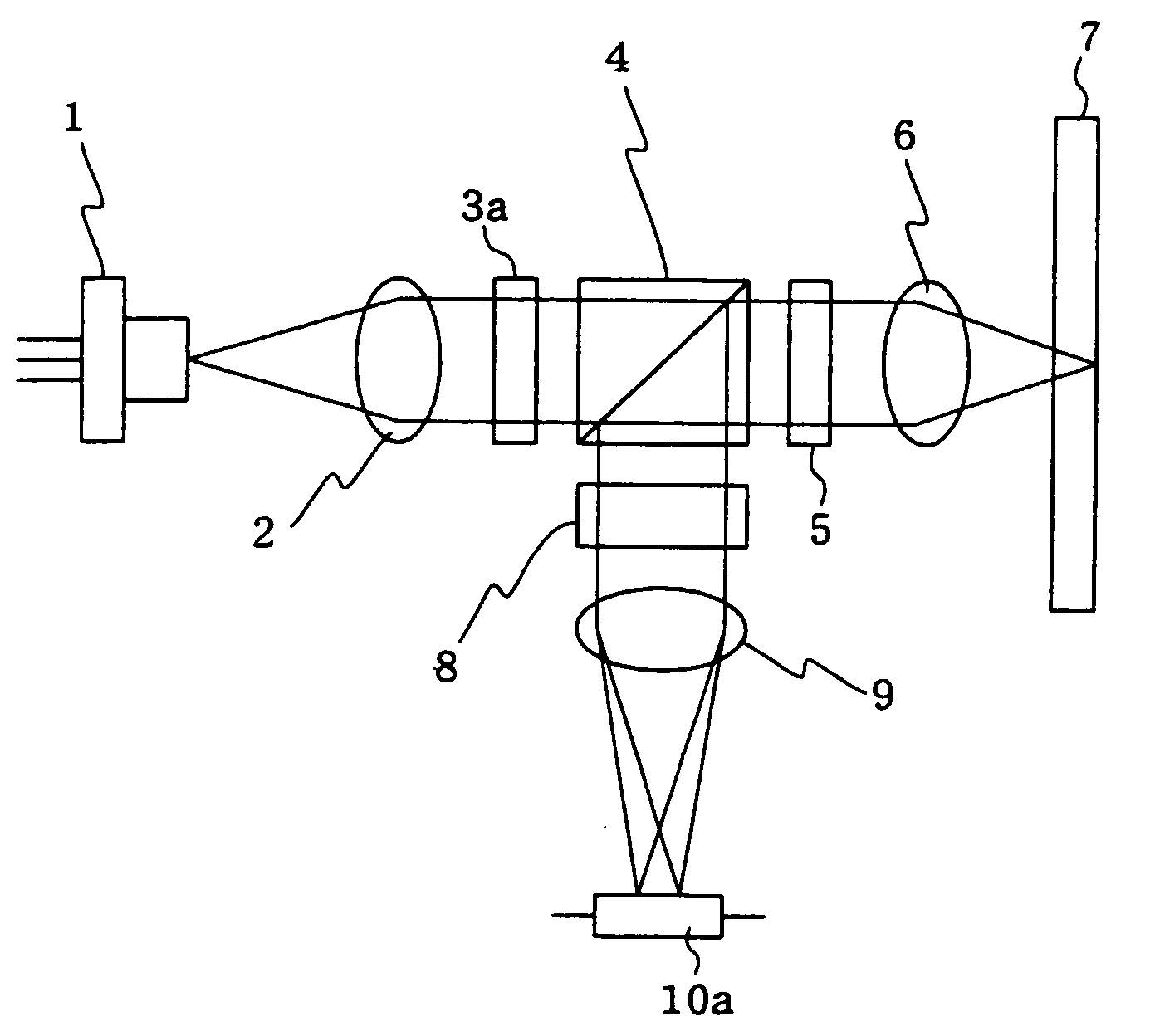

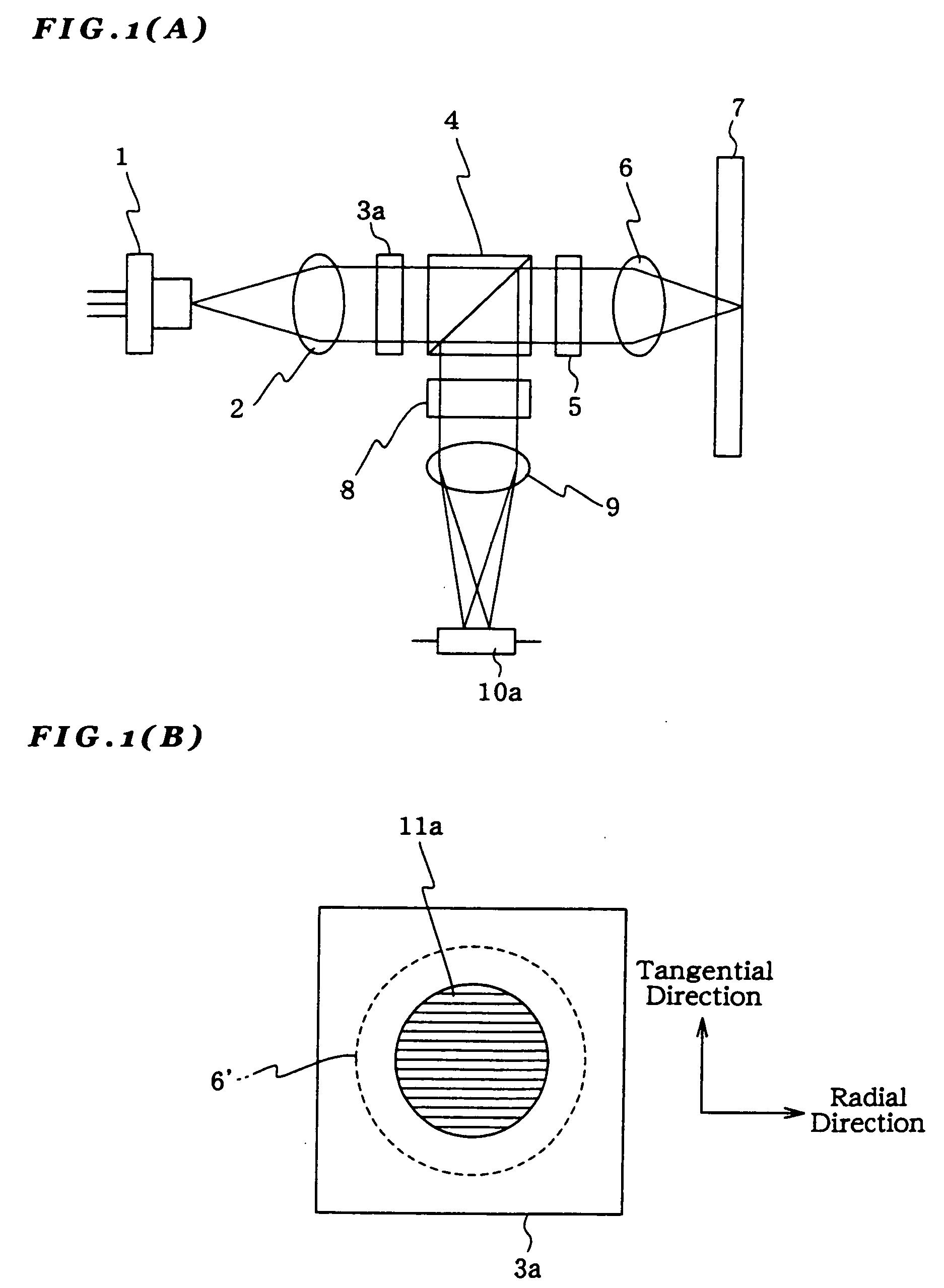

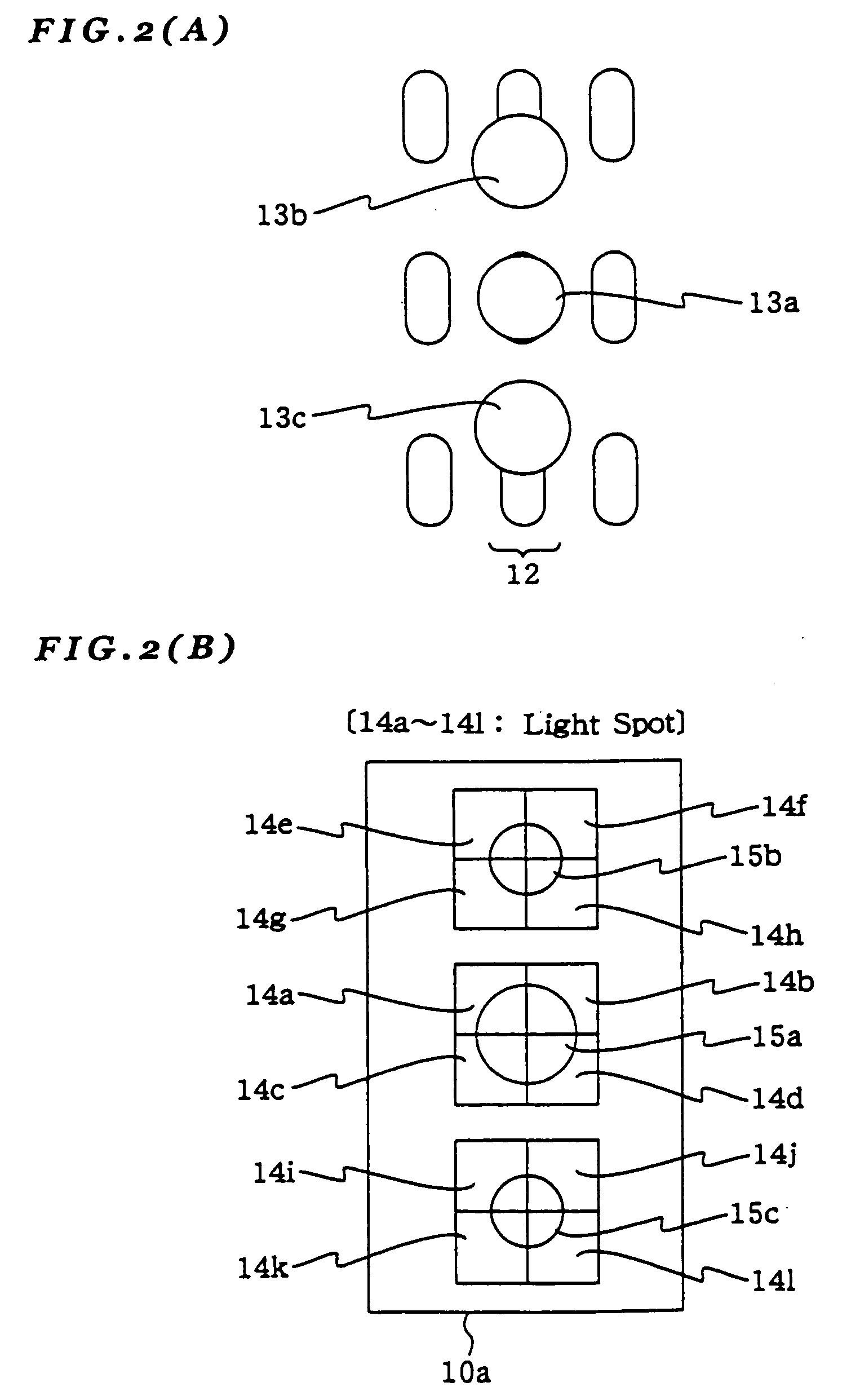

first embodiment

[0031]FIG. 1(A) shows an optical head device according to the present invention. Light emitted from a semiconductor laser 1 is collimated by a collimator lens 2. The collimated light is then divided into three light beams by a diffractive optical element 3a which are 0th-order light as a main beam and ±1st-order diffracted lights as sub-beams. The light beams enter a polarizing beam splitter 4 as P polarized light and substantially 100% transmit therethrough. Then, they transmit through quarter-wave plate 5 to be converted from linearly polarized light to circularly polarized light thereby to be focused onto a disk 7 by an objective lens 6.

[0032]Three light beams reflected from the disk 7 transmit inversely through the objective lens 6 and then transmit the quarter-wave plate 5 to be converted from the circularly polarized light to linearly polarized light whose polarization direction is orthogonal to that in the outward path. The light beams then enter the polarizing beam splitter ...

fourth embodiment

[0062]In the first to fourth embodiment, when there is residual error, caused by eccentricity of the disk 7 and the like, in the track error signal used for applying track servo, offset due to the residual error is also generated in the track error signal by the sub-beams as the radial tilt signal.

[0063]However, if the signal obtained by subtracting the track error signal used for applying the track servo from the track error signal by the sub-beams is used as the radial tilt signal, it is possible to detect radial tilt without generating offset in the radial tilt signal due to the residual error.

[0064]In a fifth embodiment of an optical head device according to the present invention, the diffractive optical element 3a in the first embodiment is replaced with a diffractive optical element 3e. FIG. 5(A) is a plan view showing the diffractive optical element 3e. The diffractive optical element 3e has the following structure. Diffraction gratings, which are divided into two regions 11e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| differential phase detection method | aaaaa | aaaaa |

| light intensity distributions | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com