Lubricant for thread rolling and thread rolling method

a technology of thread rolling and lubricant, which is applied in the field of lubricants, can solve the problems of rusting a material or a tool, complicated step of removing the chip, and decomposition of chlorine species additive components, and achieves the effects of low elongation, high hardness and easy dissolution to oils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

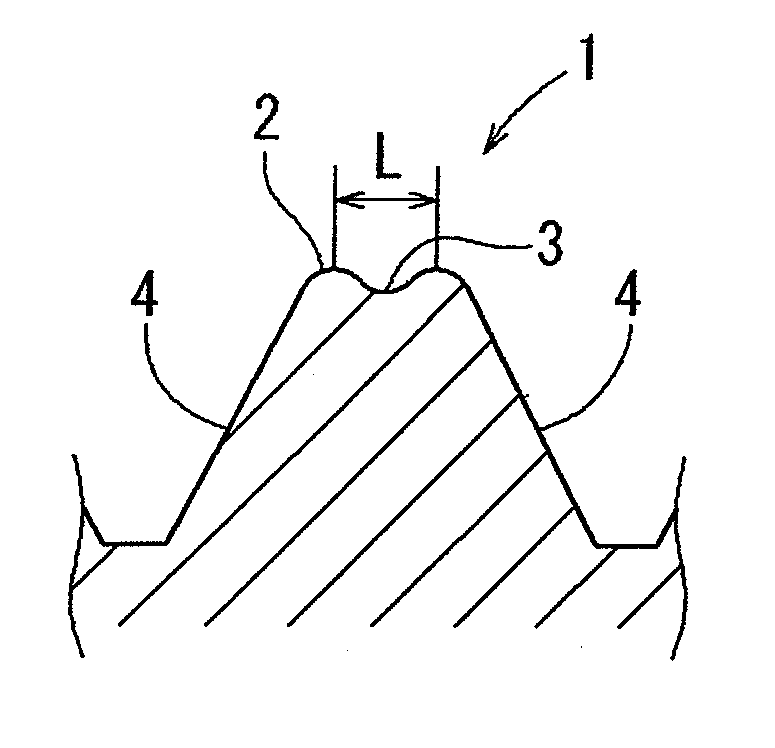

Image

Examples

examples

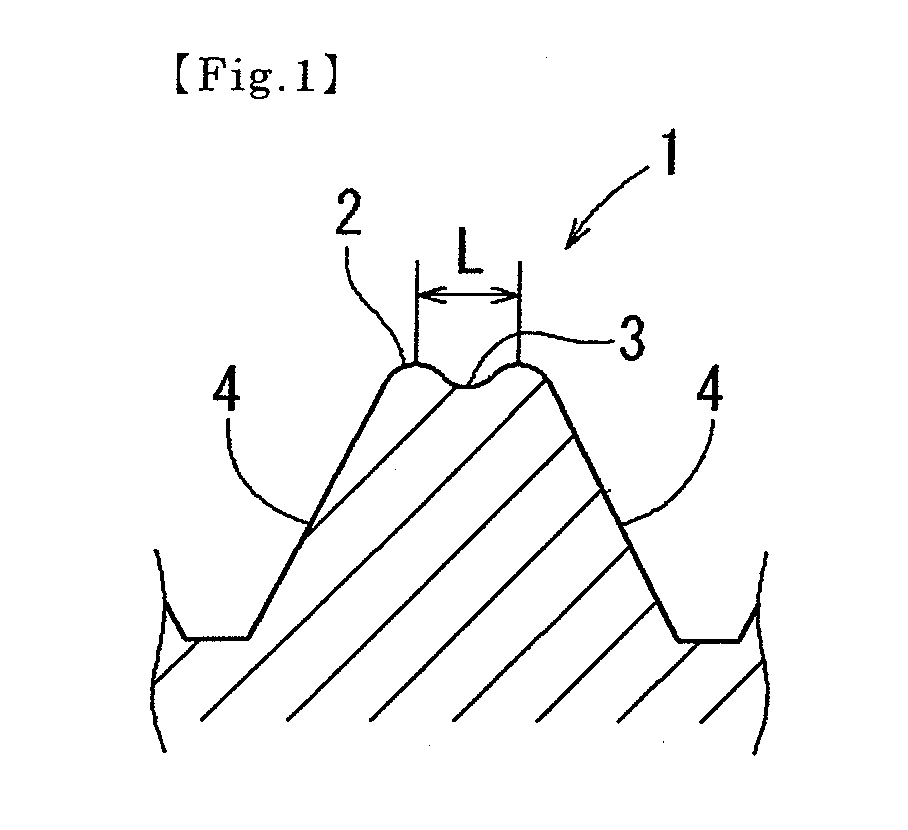

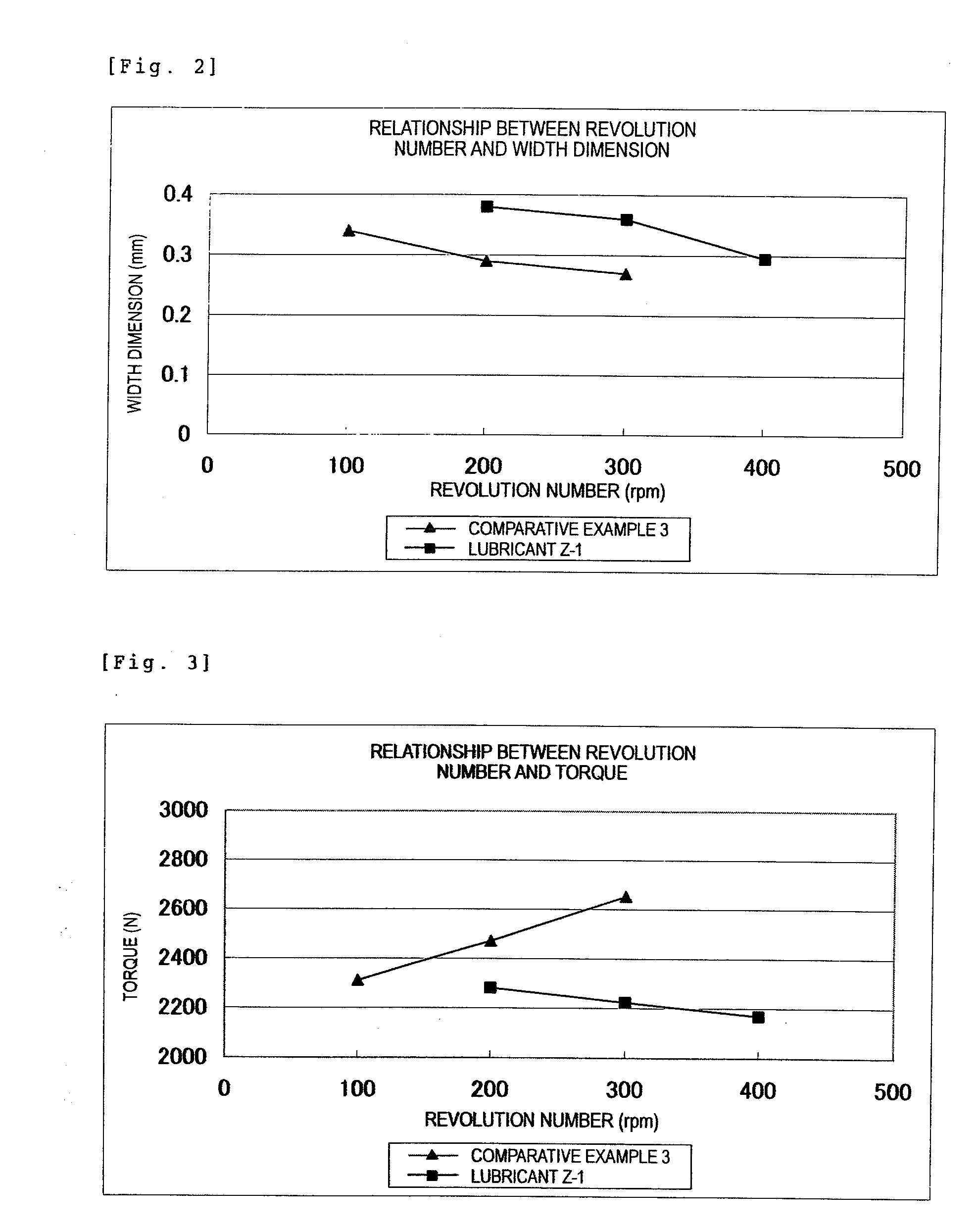

Lubricity Test

[0033]Lubricities (seizure loads) of respective lubricants and comparative examples comprising compositions shown in Table 1 through Table 4 are measured and evaluated by a four ball test. Comparative examples differ in kinds per se of additives blended. Although according to lubricant X-1, lubricant Y-1, and lubricant Z-1, respective kinds of additives blended are the same, blending rates thereof differ. Specific compositions (numerals in the table designate weight %) and a test result are shown in Table 1. Further, lubricants X-2 through X-11, lubricants Y-2 through Y-11, and lubricants Z-2 through Z-11 blending ratios of respective additives of which are variously changed are prepared by respectively constituting references by lubricant X-1, lubricant Y-1, and lubricant Z-1 and respective seizure loads are similarly measured. Compositions (numerals in table designate weight %) of lubricant X group and a test result are shown in Table 2. Compositions (numerals in tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight % | aaaaa | aaaaa |

| weight % | aaaaa | aaaaa |

| weight % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com