Launcher for a toy glider

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

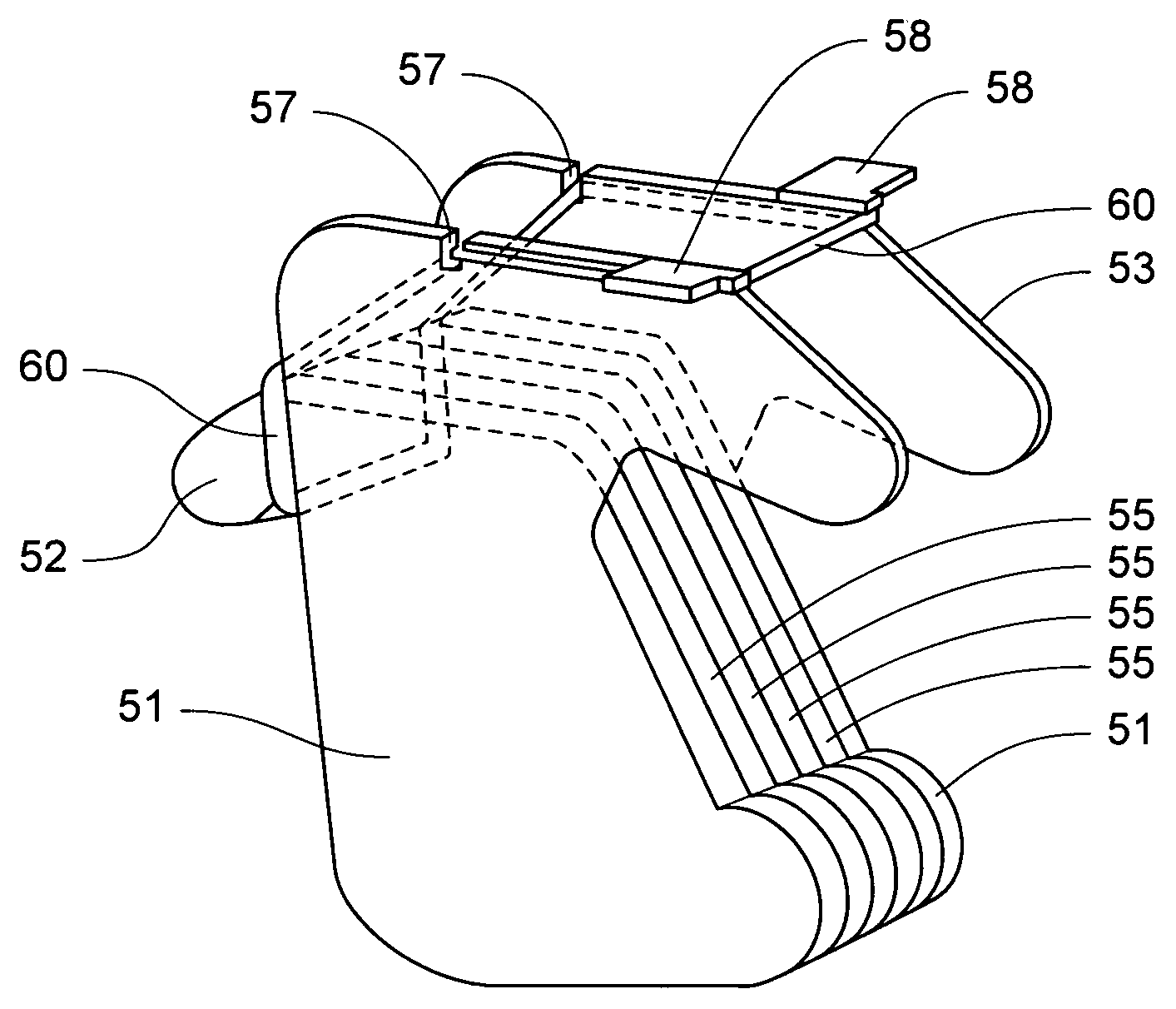

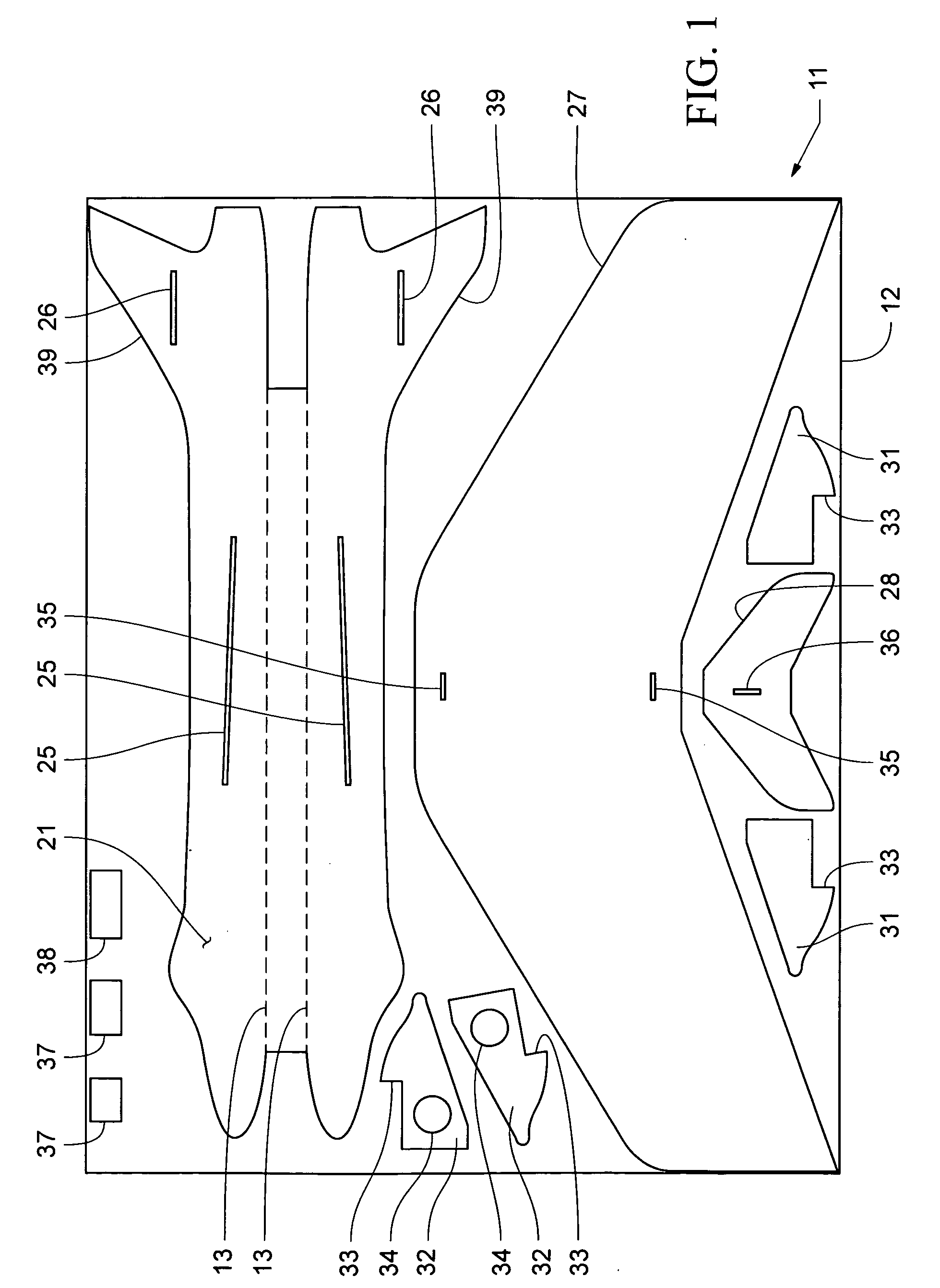

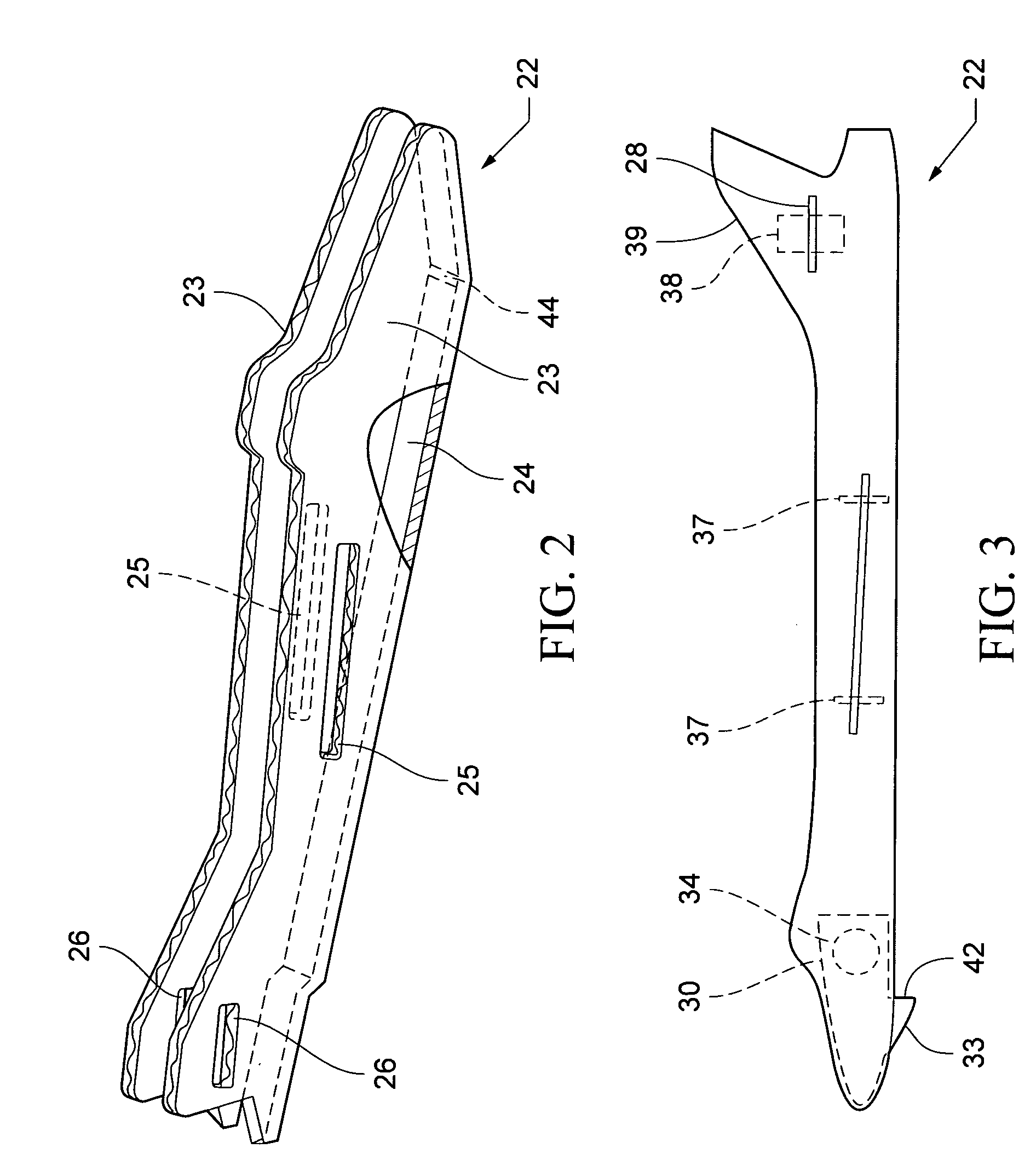

[0029]FIG. 1 is an illustration of a typical glider parts layout 11, in a sheet of corrugated paperboard 12, showing the patterned design in a pre-cut punch-out format. A couple of coins, or something with a similar weight, and some glue are all that are necessary to make the completed glider 10, shown in FIGS. 3, 4, and 5. The fuselage pattern 21, when folded along visibly scored guide lines 13, transforms into a three sided, “U” shaped beam 22 forming two uprights 23 and a bottom 24, as best illustrated in FIG. 2. The “U” shape provides the fuselage with built-in stiffness and cross-sectional strength. The two uprights 23 have the same profile, showing the silhouette and reproduction of the glider model on its outside surfaces. Each upright has cutout slots, positioned in line, for inserting a wing 27 through slots 25 and a horizontal stabilizer 28 through slots 26. Score lines at each wing tip provides fine-tuning of the glider's flying performance.

[0030]An interposing weight pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com