Manufacturing method for wide-range fine-grained magnesium alloy thin-sheet material

a technology of fine-grained magnesium alloy and manufacturing method, which is applied in the field of sheet material, can solve the problems of low heat content, difficult to perform metal plastic rolling process, and restricted thickness reduction ratio of rolling, and achieve the effect of reducing manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

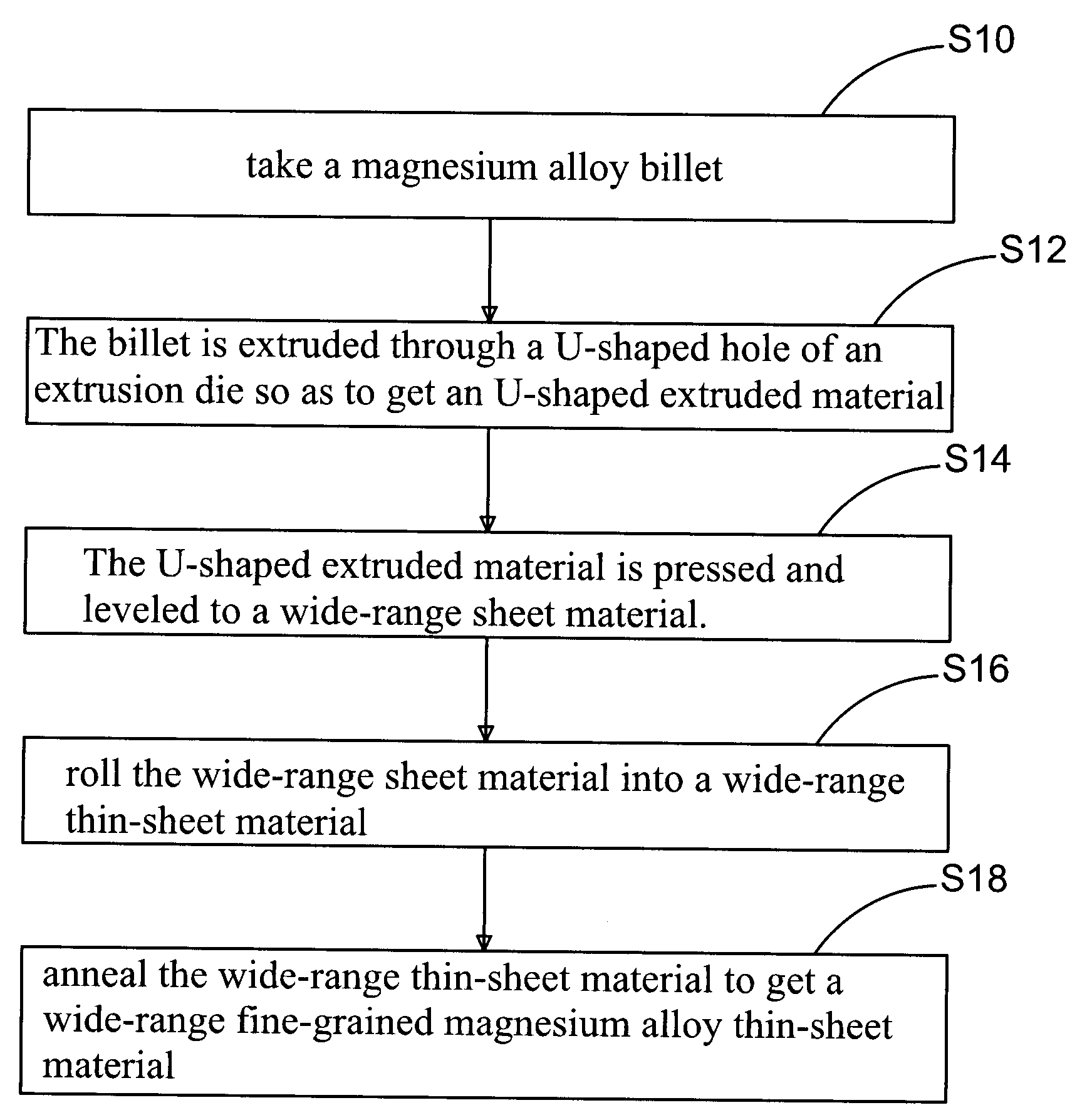

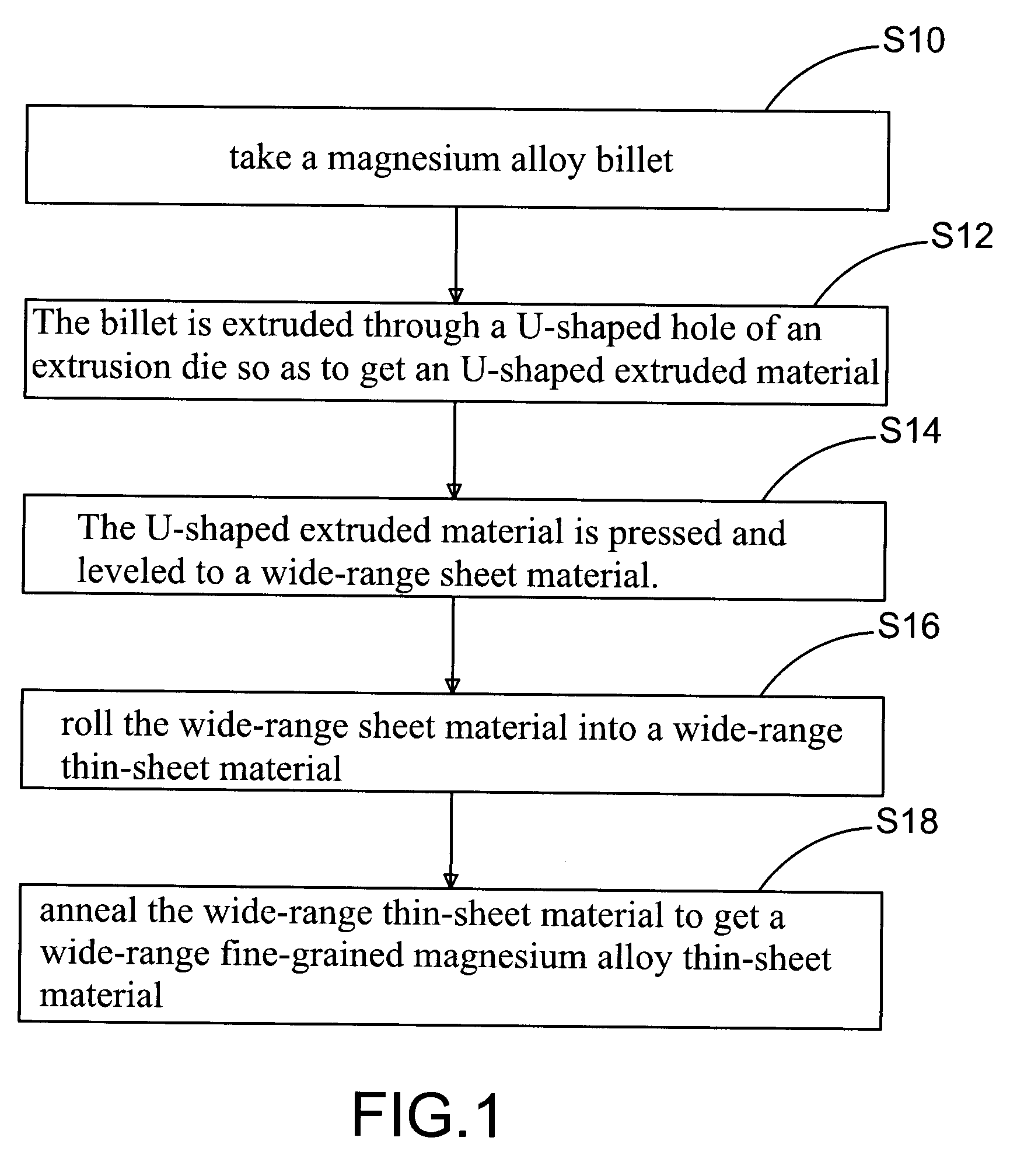

[0024]In order to manufacture a wide-range magnesium alloy thin-sheet material that satisfies requirements of cases of 3C products, a manufacturing method for wide-range fine-grained magnesium alloy thin-sheet material includes following steps:

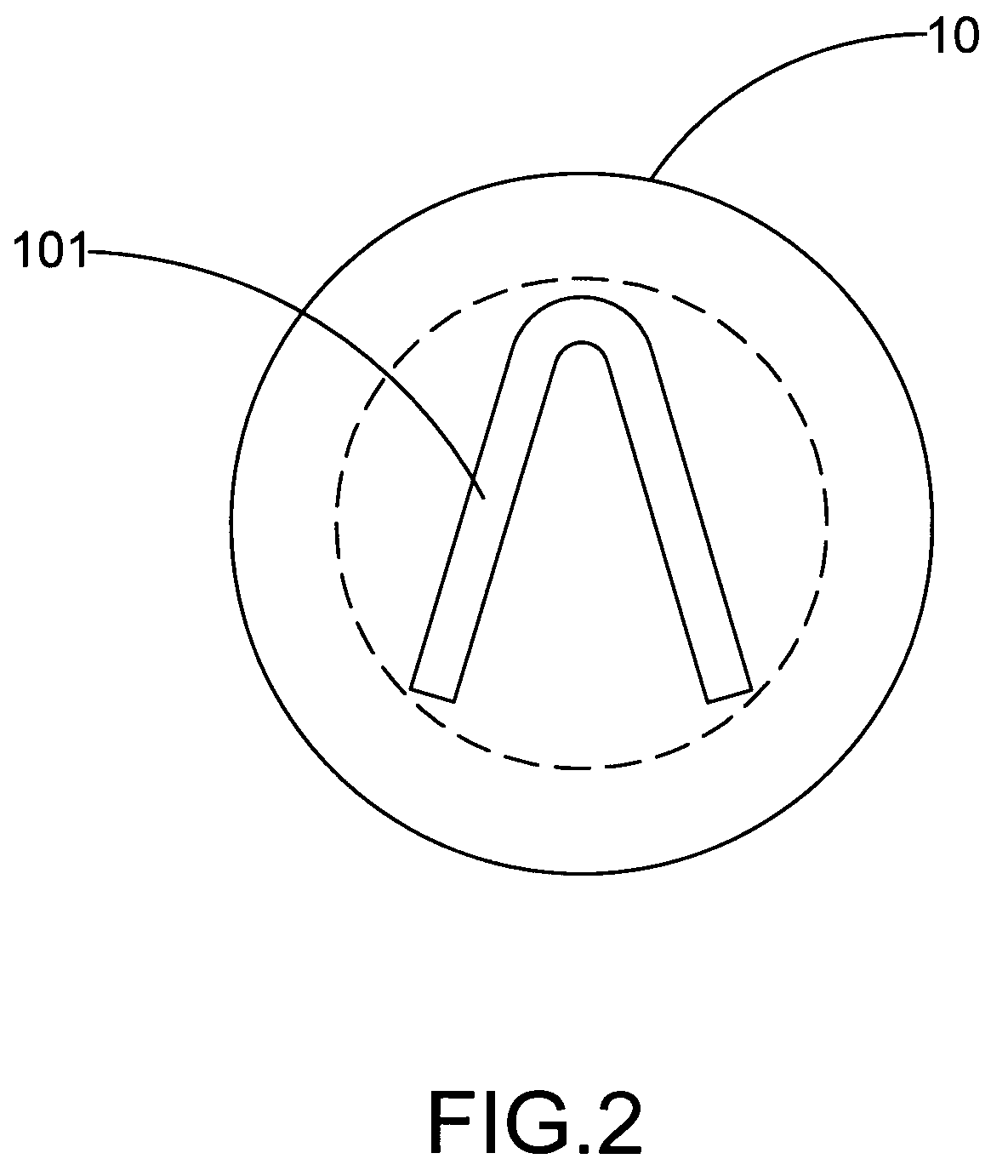

[0025]In the beginning, run the step S10, take a magnesium alloy billet. Then, perform an extrusion process, as shown in the step S12. The billet is extruded through a U-shaped hole 101 of an extrusion die 10 so as to get an U-shaped extruded material 2. Refer to FIG. 2, ratio of diameter of the U-shaped hole 101 to the extrusion die 10 is smaller than 0.7. The thickness of the U-shaped hole 101 ranges from 1.5 mm to 5 mm while 2.0 mm is preferred. The U-shaped extruded material 2 produced by the extrusion process is shown in FIG. 3.

[0026]Refer to the step S14, perform a pressing and leveling process. The U-shaped extruded material 2 is pressed and leveled to a wide-range sheet material. Before performing the pressing and leveling process, cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com