Ergonomically designed dispenser for stretch film

a dispenser and ergonomic design technology, applied in the direction of thin material handling, packaging, filament handling, etc., can solve the problems of difficult to push the dispenser into the core, the dispenser cannot adjust to the variations of the inside dimensions of the film core, and the film roll cannot be rolled. achieve the effect of good balance and facilitate the application of film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

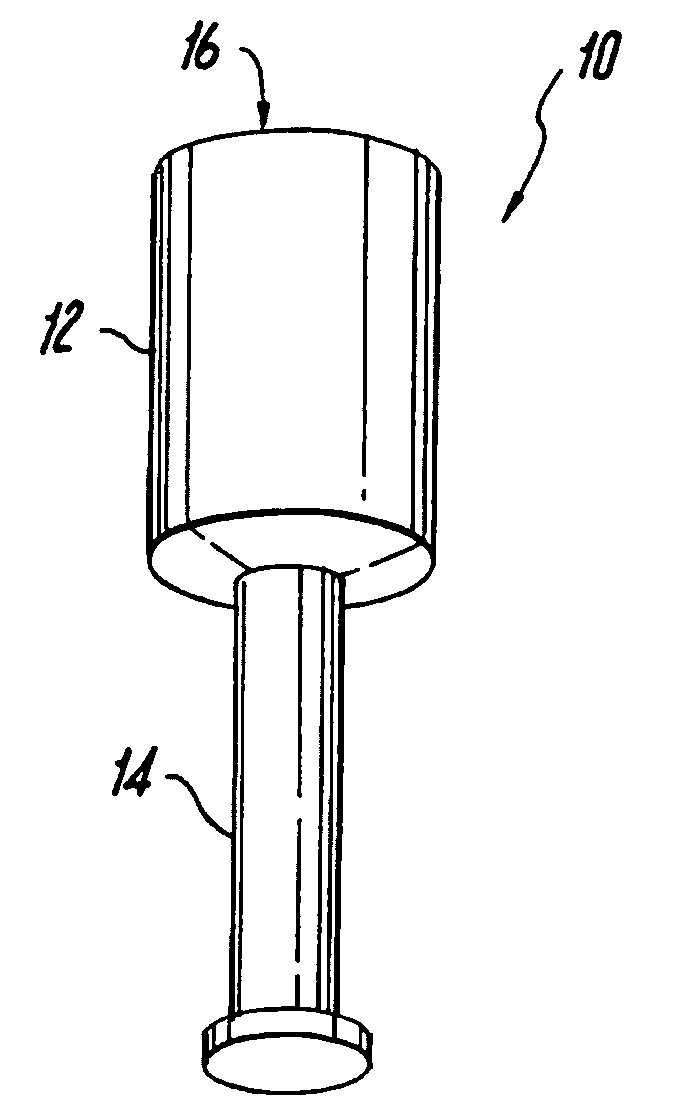

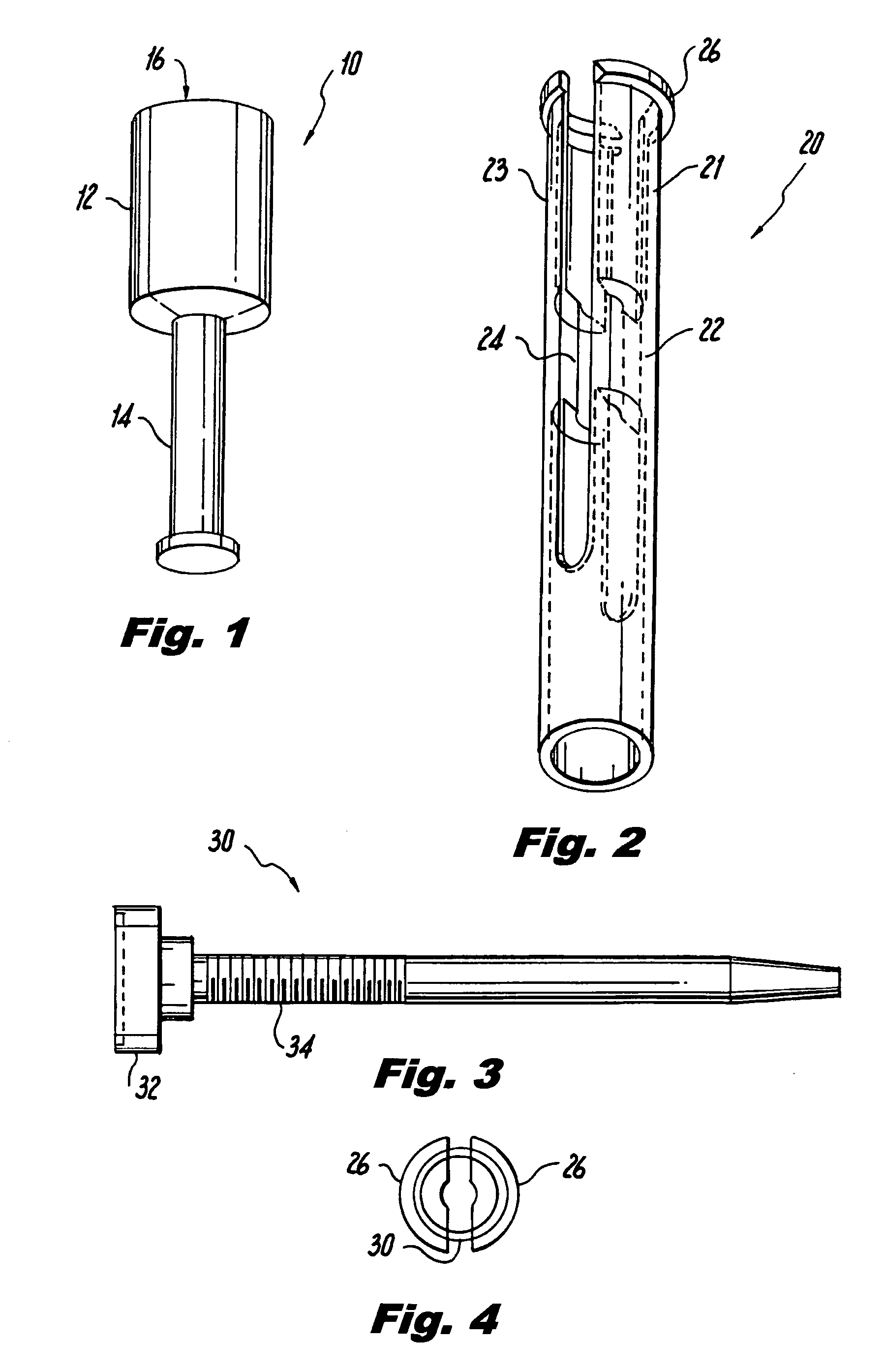

[0034]FIG. 1 shows a dispenser 10 for dispensing stretch film 12 having a handle 14. The handle 14 in a preferred embodiment being molded. In a preferred embodiment, the dispenser 10 has a foam sleeve for a cushion grip which fits over the handle 14.

[0035]FIG. 2 shows the barrel or shaft 20 of the dispenser 10. The barrel or shaft 20 of the dispenser 10 is split into two pieces 21 and 23 which allows the barrel 20 to be compressed and easily inserted into the film core 16. The barrel has located internally two cams 22 and 24. In a preferred embodiment, the front end of the barrel 20 has a raised lip 26. After the barrel 20 is inserted into the film core 16, the raised lip 26 extends beyond the end of the core 16 and prevents the stretch film 12 from coming out of the dispenser 10.

[0036]FIG. 3 shows the tensioning device 30 of the dispenser 10 of the present invention. The tensioning device 30 comprises a knob 32 at the base of the tensioning device 30 and a tapered screw 34. The ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com