Refrigerant compressor arrangement

a compressor and refrigerant technology, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of user inconvenience and other problems, and achieve the effect of saving weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

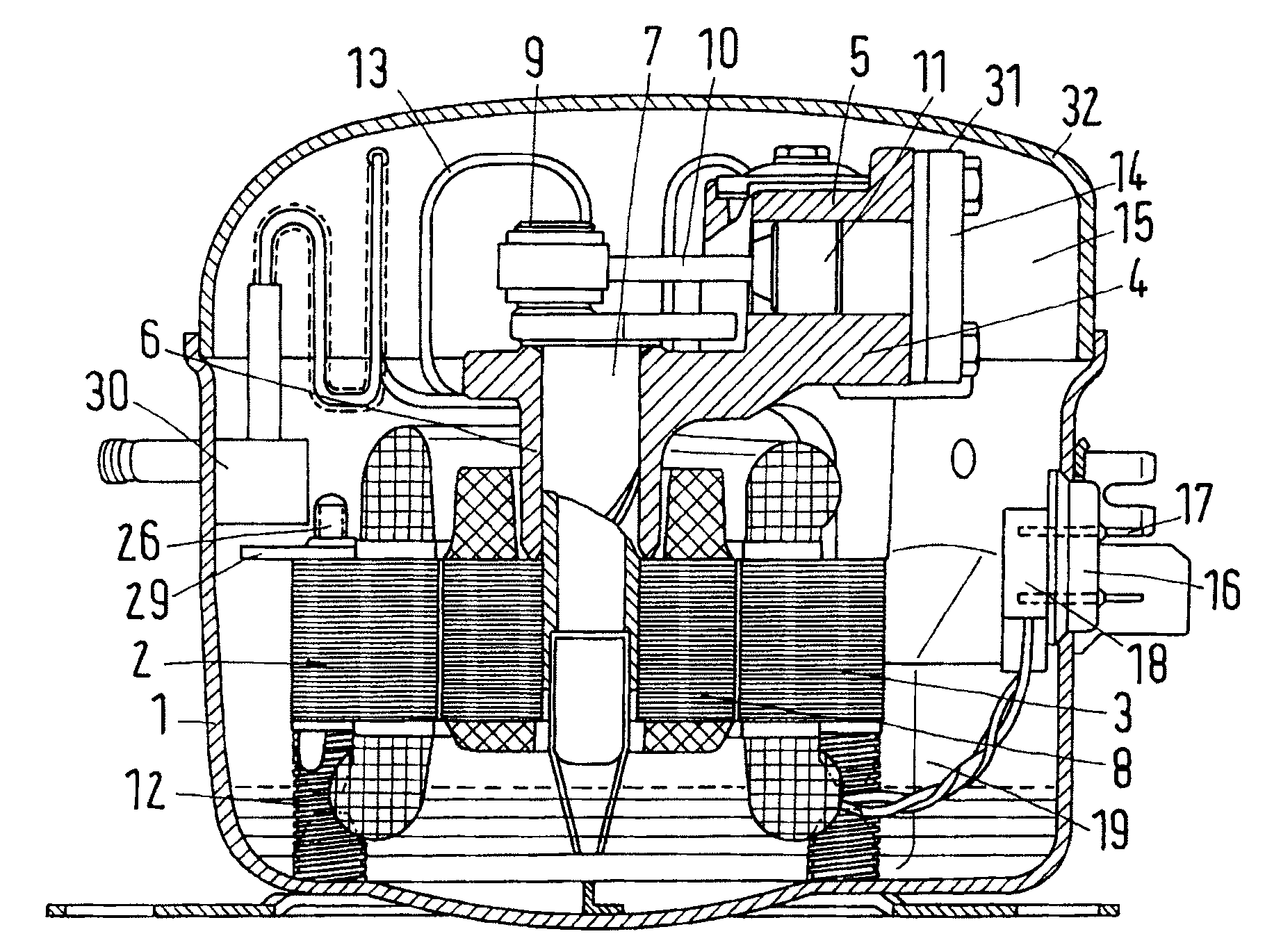

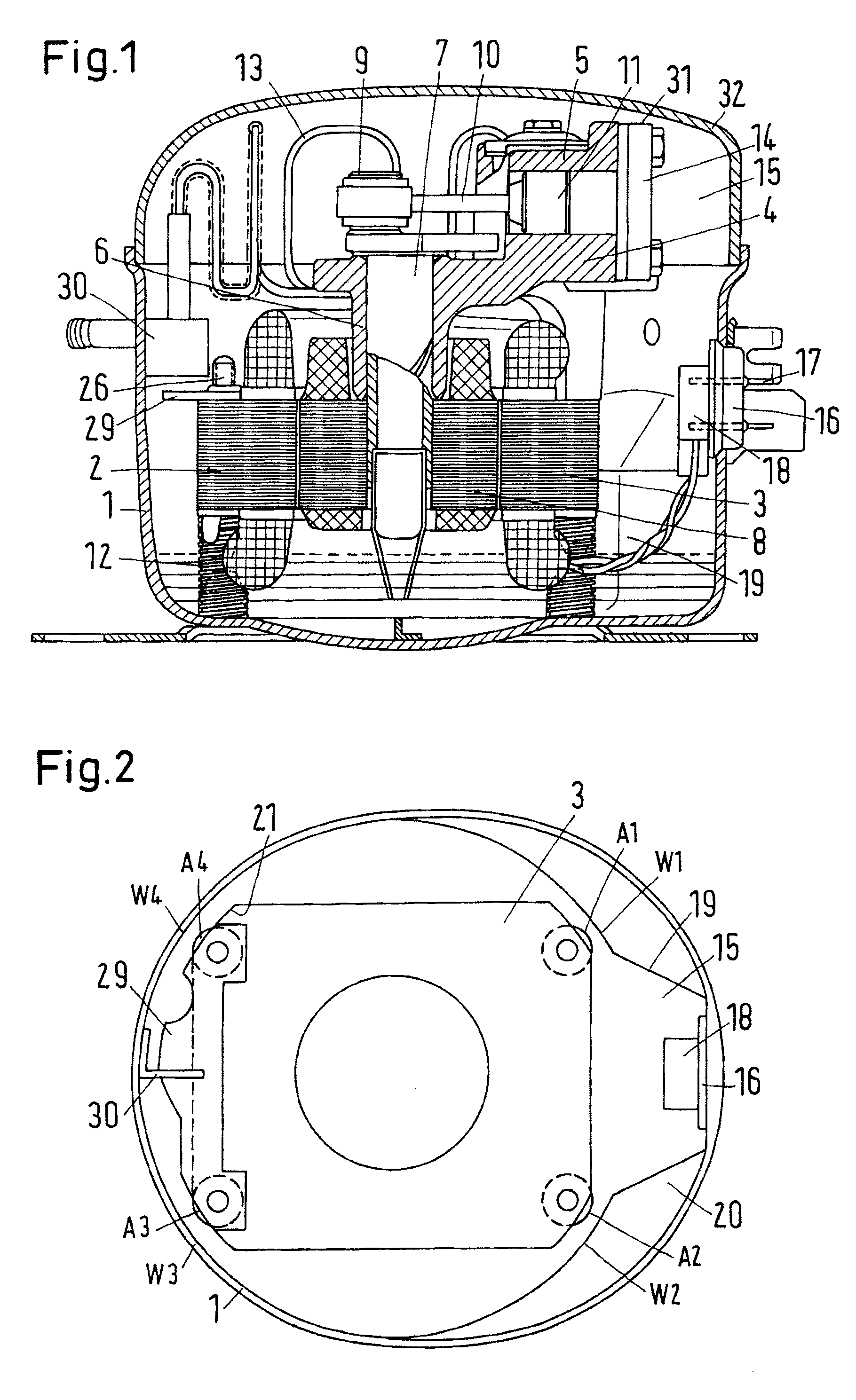

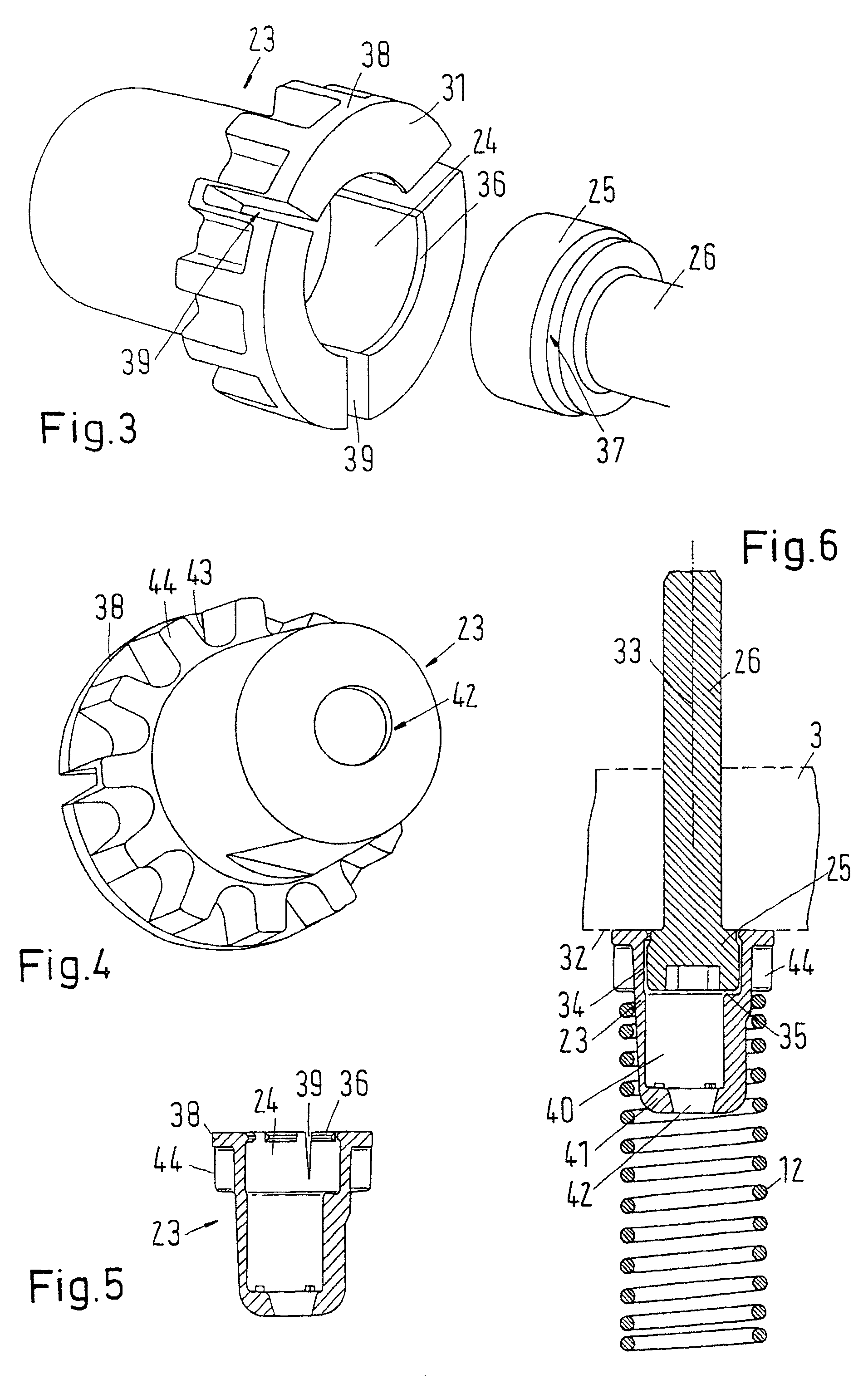

[0027]A compressor unit 2 is arranged in a case 1. A compressor housing 4 is connected to a stator 3 of an electric motor, the compressor housing 4 comprising a cylinder 5 and a bearing 6. In the bearing 6 a motor shaft 7 is supported, which carries a rotor 8 and drives a piston 11 via a crank pin 9 and a connecting rod 10, the piston 11 reciprocating in the cylinder 5. Helical compression springs 12 provide an elastic support for the compressor unit 2 in the case 1. Also a pressure pipe 13 is made to be elastic.

[0028]For adopting a cylinder head 14 projecting radially over the stator 3, an enlargement 15 is provided in the case 1. This enlargement also comprises an electric bushing 16 with bushing pins 17, whose inner ends carry a plug 18. In the bottom part of the case 1, both sides of the bushing 16 are provided with concavities 19 and 20. In this way, the wall of the case 1 forms four abutments W1-W4, which can interact with four stops A1-A4, which are arranged on the compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com