Copper plating method and apparatus for a gravure cylinder

a gravure cylinder and copper plating technology, applied in the direction of printing, electrolysis processes, electrolysis components, etc., can solve the problems of reducing affecting the service life of the gravure cylinder, so as to reduce the consumption of additives and reduce the power supply cost. , the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

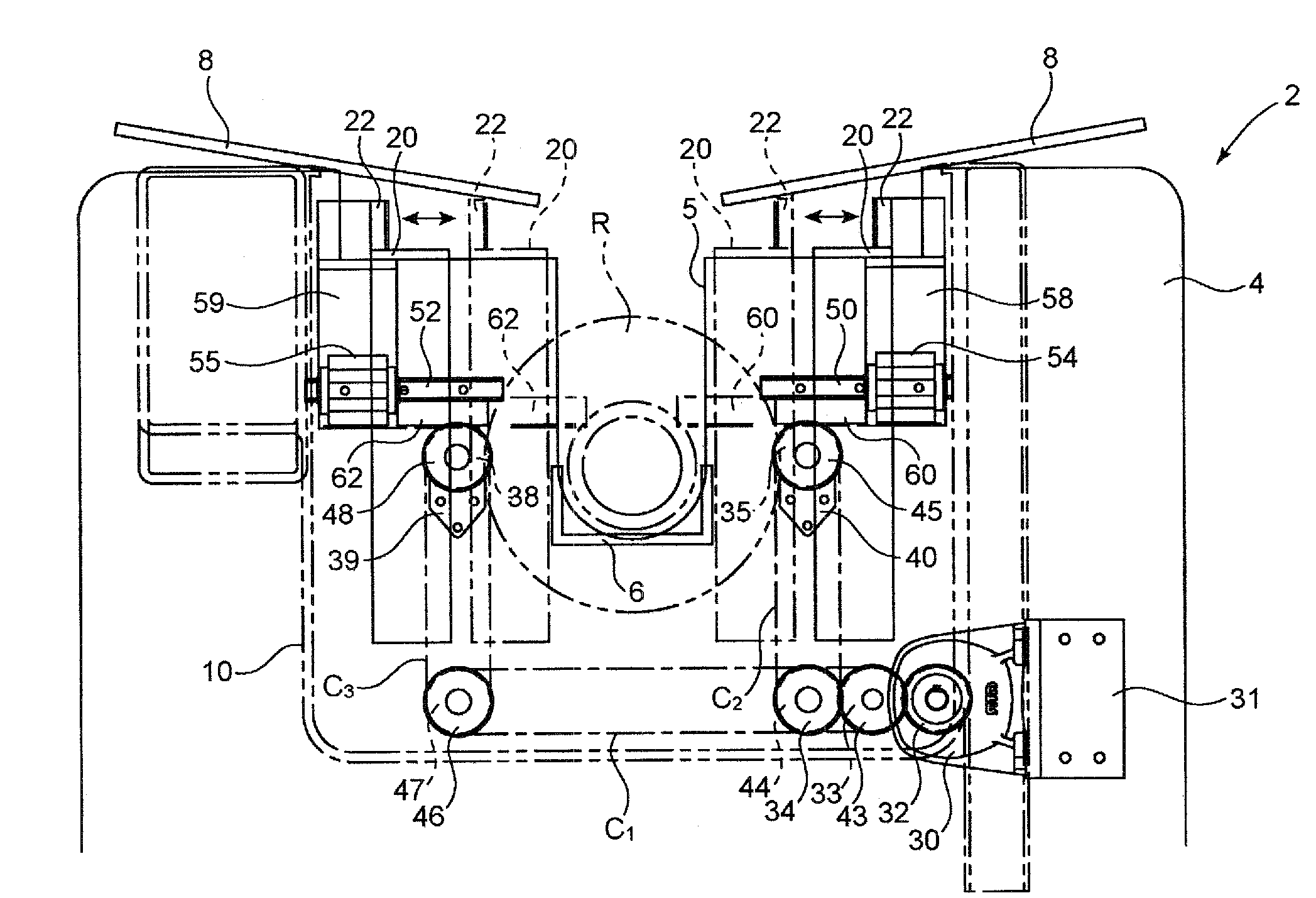

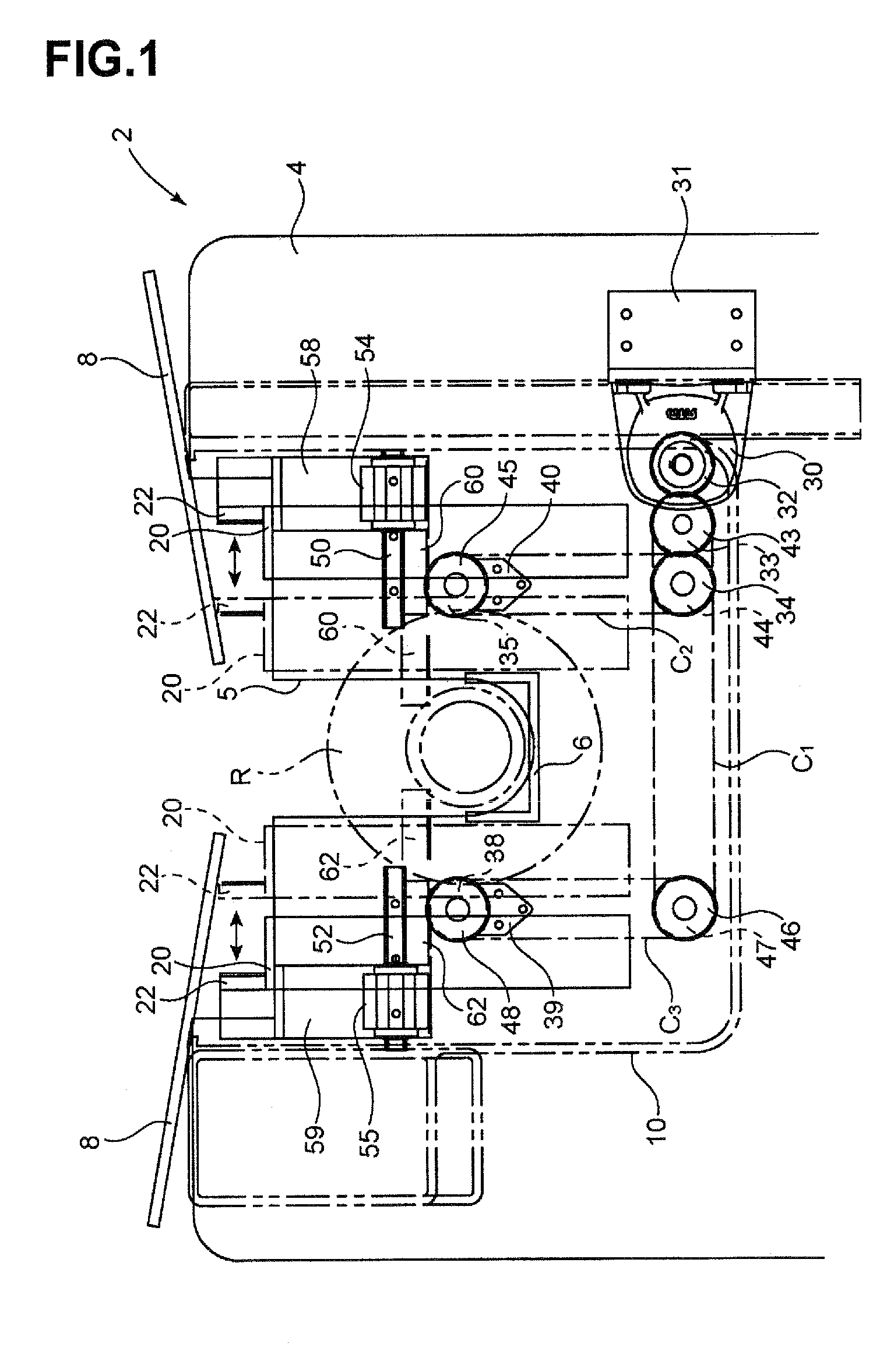

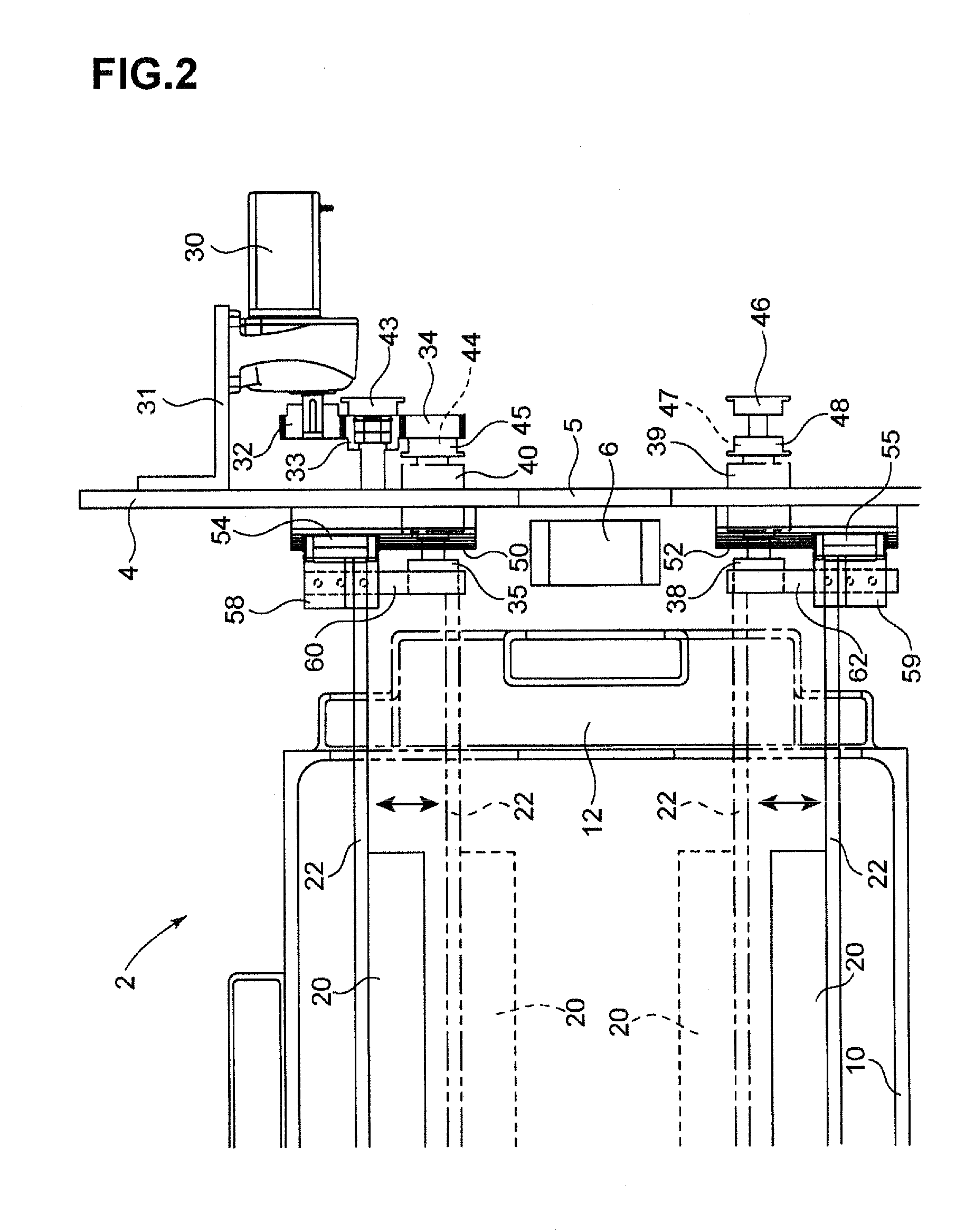

[0043]As a gravure cylinder, a cylindrical base with an aluminum core having a circumference of a circle of 450 mm and a full length of 1100 mm was used. The gravure cylinder was placed in a plating bath under the condition that both ends of the gravure cylinder were chucked. Anode chambers were brought close to gravure cylinder side surfaces up to an interval of 20 mm with a slide mechanism controlled by a computer, and the copper plating solution was overflowed, whereby the gravure cylinder was soaked completely. With the rotation speed of the gravure cylinder being set to be 120 ppm, copper plating was provided at a liquid temperature of 40° C., a current density of 18 A / dm2, and a voltage of 5.4 V until the thickness became 80 μm. The time required for a plating treatment was about 20 minutes. There were no rashes and pits on a plating surface, and plating with a uniform thickness was provided over the full length of the gravure cylinder. Furthermore, the copper plating solution...

example 2

[0044]As a gravure cylinder, a cylindrical base with an aluminum core having a circumference of a circle of 600 mm and a full length of 1100 mm was used. The gravure cylinder was placed in a plating bath. Anode chambers were brought close to the gravure cylinder up to an interval of 20 mm with a slide mechanism controlled by a computer, and the plating solution was overflowed, whereby the gravure cylinder was soaked completely. With the rotation speed of the gravure cylinder being set to be 120 ppm, copper plating was provided at a liquid temperature of 40° C., a current density of 18 A / dm2, and a voltage of 6.0 V until the thickness became 80 μm. The time required for a plating treatment was about 20 minutes. There were no rashes and pits on a plating surface, and plating with a uniform thickness was provided over the full length of the gravure cylinder. Furthermore, the copper plating solution automatic control mechanism was operated normally, and the composition of the copper pla...

example 3

[0045]As a gravure cylinder, a cylindrical base with an aluminum core having a circumference of a circle of 940 mm and a full length of 1100 mm was used. The gravure cylinder was placed in a plating bath under the condition that both ends of the gravure cylinder were chucked. Anode chambers were brought close to the gravure cylinder up to an interval of 20 mm with a slide mechanism controlled by a computer, and the plating solution was overflowed, whereby the gravure cylinder was soaked completely. With the rotation speed of the gravure cylinder being set to be 120 ppm, copper plating was provided at a liquid temperature of 40° C., a current density of 18 A / dm2, and a voltage of 7.7 V until the thickness became 80 μm. The time required for a plating treatment was about 20 minutes. There were no rashes and pits on a plating surface, and plating with a uniform thickness was provided over the full length of the gravure cylinder. Furthermore, the copper plating solution automatic contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com