Propellants and high energy materials compositions containing nano-scale oxidizer and other components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0029]In a first embodiment a nano-scale composite particle referred to herein as a nano-reactor is formed to provide the propellant composition. A precursor solution is prepared with a desired concentration of components. For example, the solution may contain ammonium perchlorate (AP), polymer and nano-scale AI particles forming a precursor or nano-scale aluminum. The solution is atomized and dried by the low temperature drying methodology discussed. In one embodiment of the propellant composition, liquid oxidizer droplets can be encapsulated by a suitable coating agent prior to drying. The dried particles now comprise a composite material of all ingredients needed to form a nano-scale reactor material. The schematic of this procedure is shown in FIG. 1. The formulation is particularly useful for explosives or propellants not containing reactive metal additives.

second embodiment

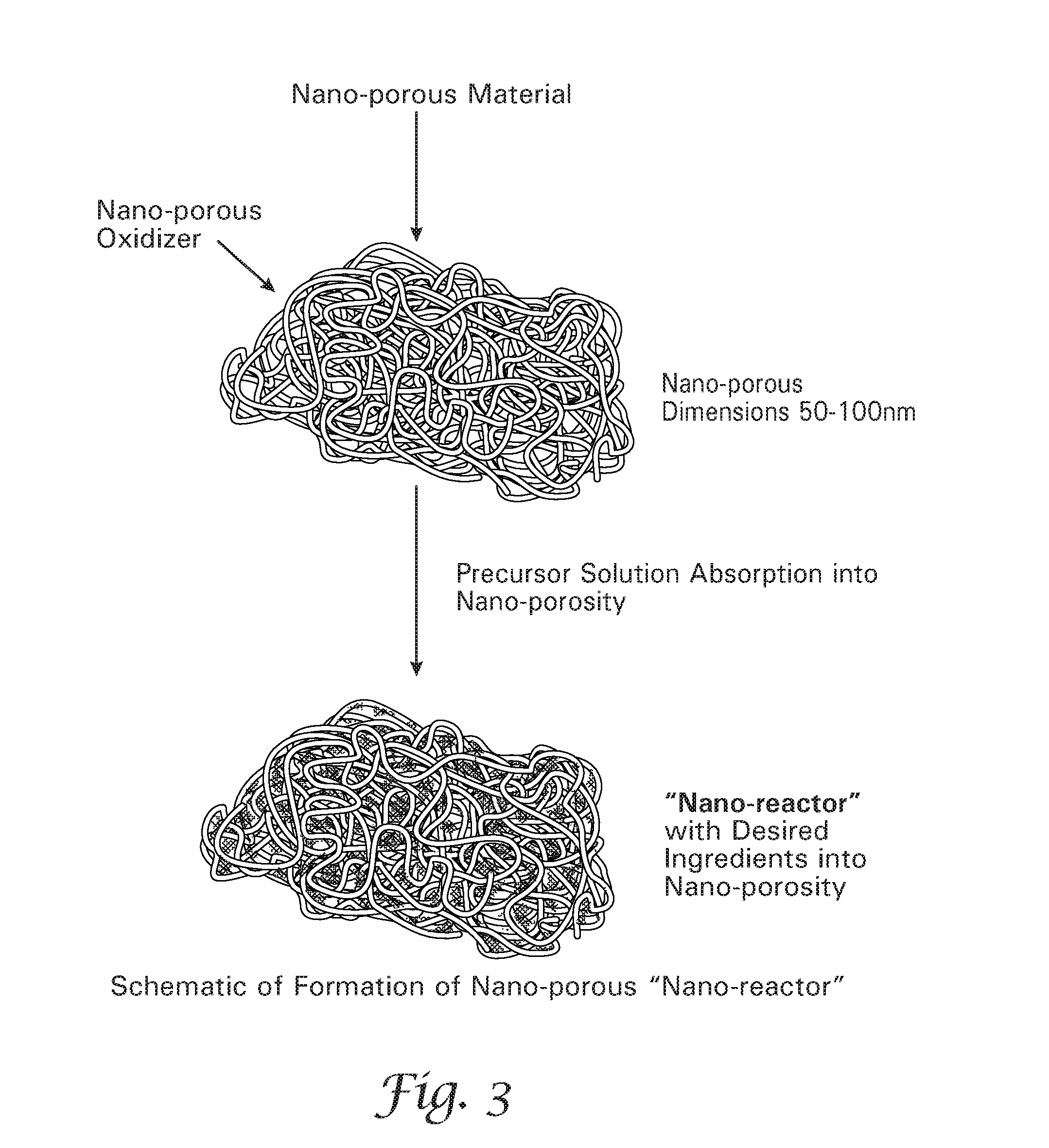

[0030]In a second embodiment a nano-scale porous material is formed to provide the propellant composition. Where the ingredients are highly porous structures made up of nano primary particles, the porous structure allows preferential coating of ingredients. The oxidizer material is dried to form nano-sized porous materials using the low temperature drying methods discussed. After formation the nano-scale porous oxidizer is filled with other ingredients by absorption or filling in of the nano-porous structure of the porous oxidizer material.

[0031]Propellant formation may be varied by selective coating and co-dissolving with precursors, providing for nano-scale coating of the particles. For example, depending on reactivity of oxidizer, fuel and metallic fuel reactivity and how each individually stabilizes in the particle, selective processing is necessary. In other words, the components of the propellant ingredient may have to be protected from each other.

[0032]As shown in FIG. 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com