Thermal barrier deposited directly on monocrystalline superalloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Preferably, the zirconia can be stabilized with at least one oxide of an element selected from the group constituted by dysprosium, erbium, europium, gadolinium, samarium, ytterbium, yttrium, or with a combination of a tantalum oxide and at least one oxide of an element in this group, or with a combination of a niobium oxide and at least one oxide of an element in this group.

[0020]More preferably, the zirconia is stabilized with an yttrium oxide.

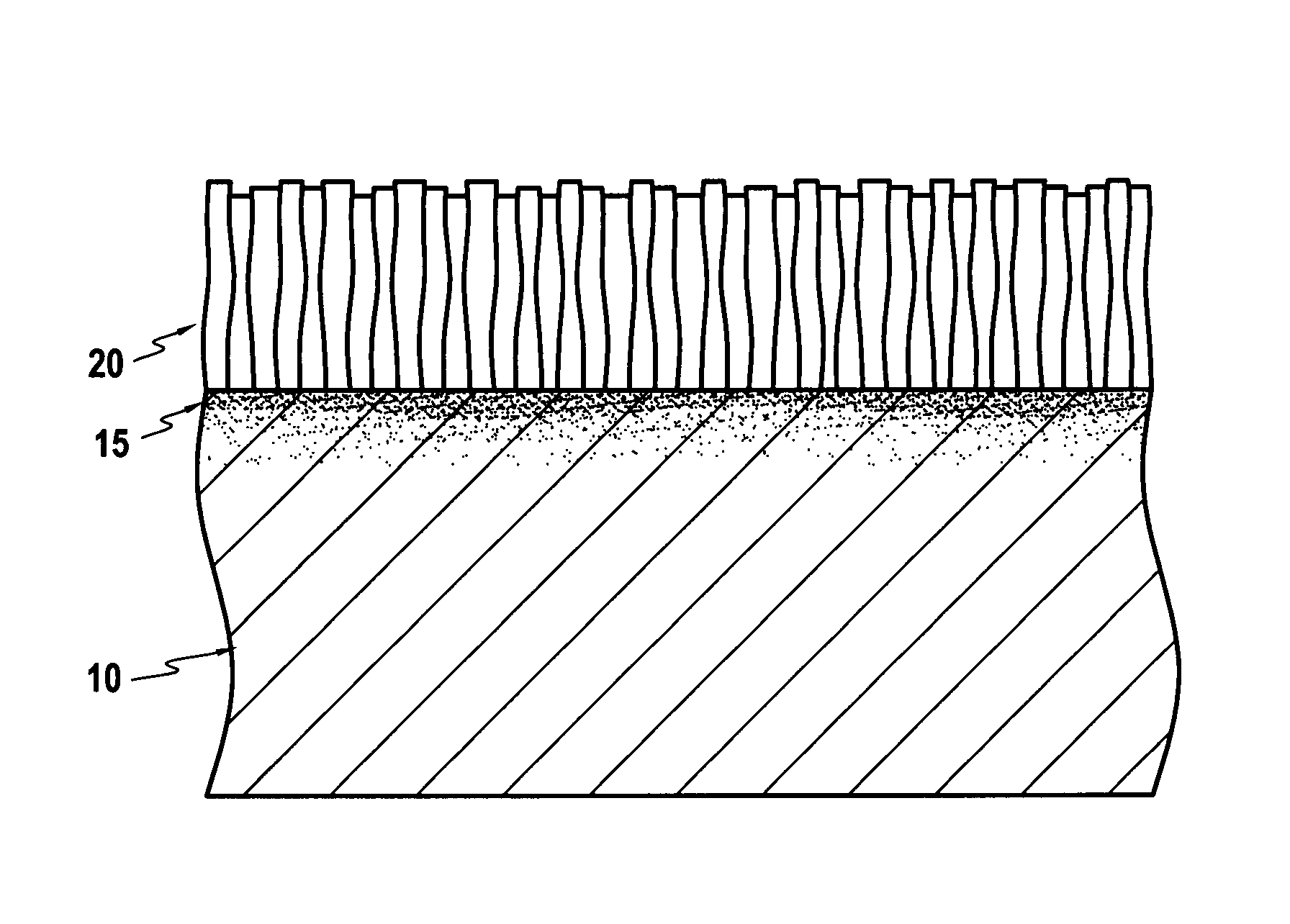

[0021]The ceramic is deposited by the electron beam physical vapor deposition (EBPVD) method. The ceramic is supplied in the form of a powder that, once vaporized by the electron beam, condenses on the MCNG superalloy to form a ceramic layer 20. Because an electron beam is used, it is necessary to maintain a primary vacuum in the enclosure containing the electron beam, the ceramic for deposition, and the MCNG superalloy substrate. The ceramic layer 20 deposited by the EBPVD method presents a structure in the form of adjacent columns 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com