Percussion Mechanism and at Least Percussively-Operated Hand Machine Tool With a Percussion Mechanism

a percussion mechanism and hand machine tool technology, applied in the direction of mechanical equipment, machines/engines, manufacturing tools, etc., can solve the problems of affecting the performance of the elastomer material, the cost of the steel version proposed is quite high, and the minimum tolerance cannot be exceeded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

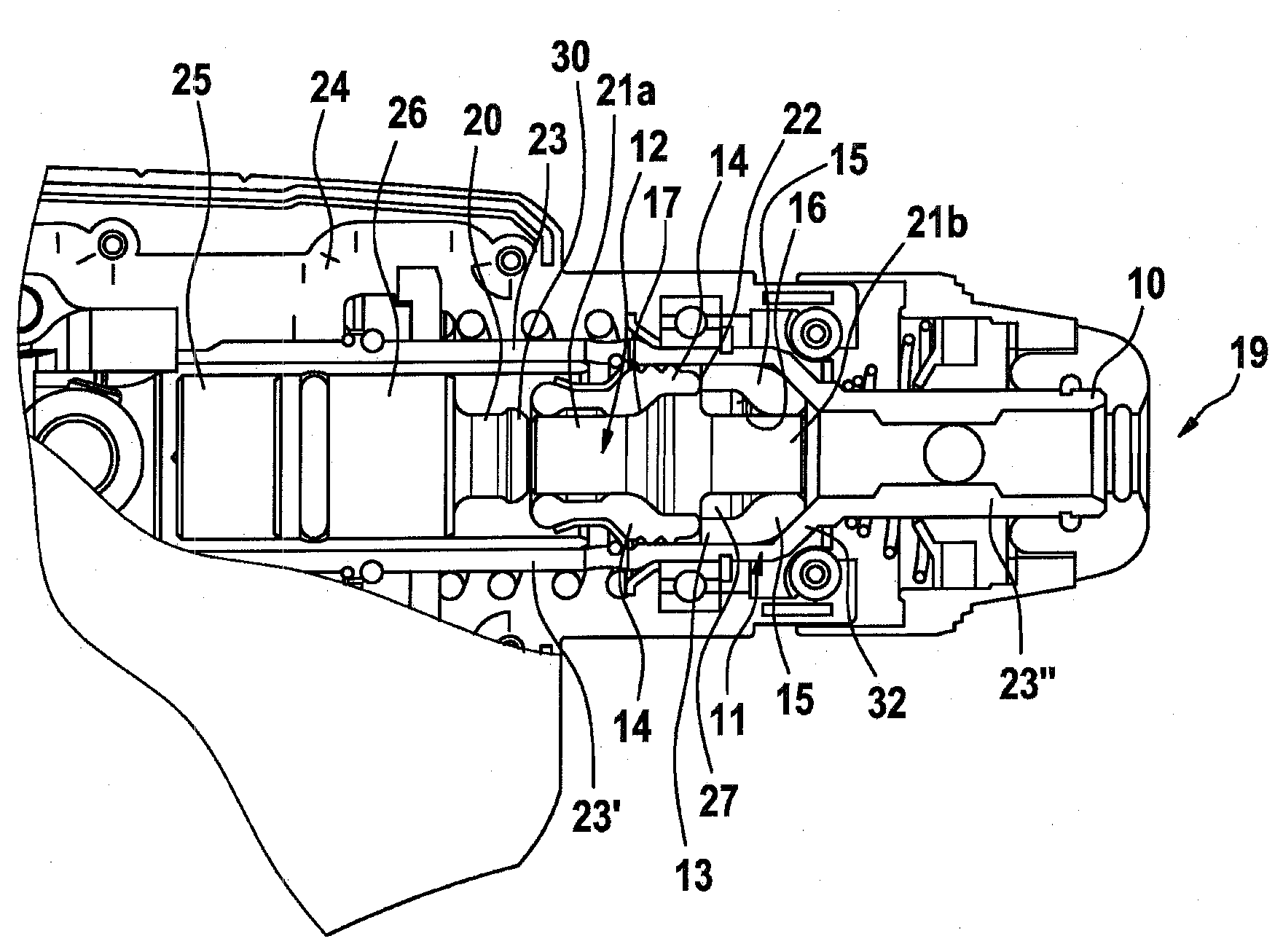

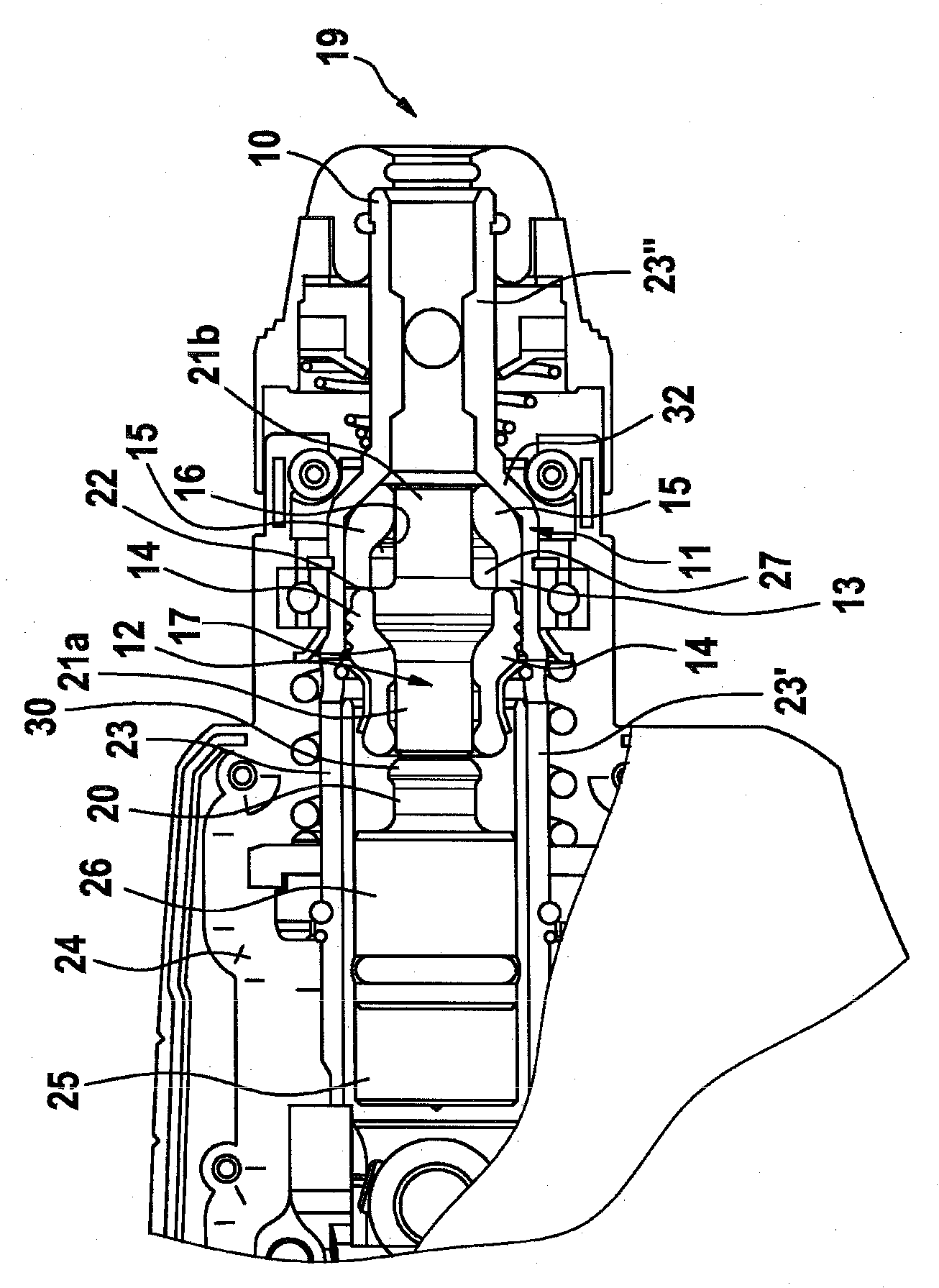

[0014]In FIG. 1, part of an electric hand power drill or percussion hammer with a percussion mechanism is shown in longitudinal section. The percussion mechanism essentially includes a percussion bolt guide 11 and a percussion bolt 12, which is axially displaceable in the percussion bolt guide 11 and which transmits the percussion pulse of a beater 20 of the percussion mechanism, which is driven by a drive motor, not shown, of the handheld drill hammer or percussion hammer, to a drilling or percussion tool 19 inserted into a tool holder 10 of the percussion mechanism.

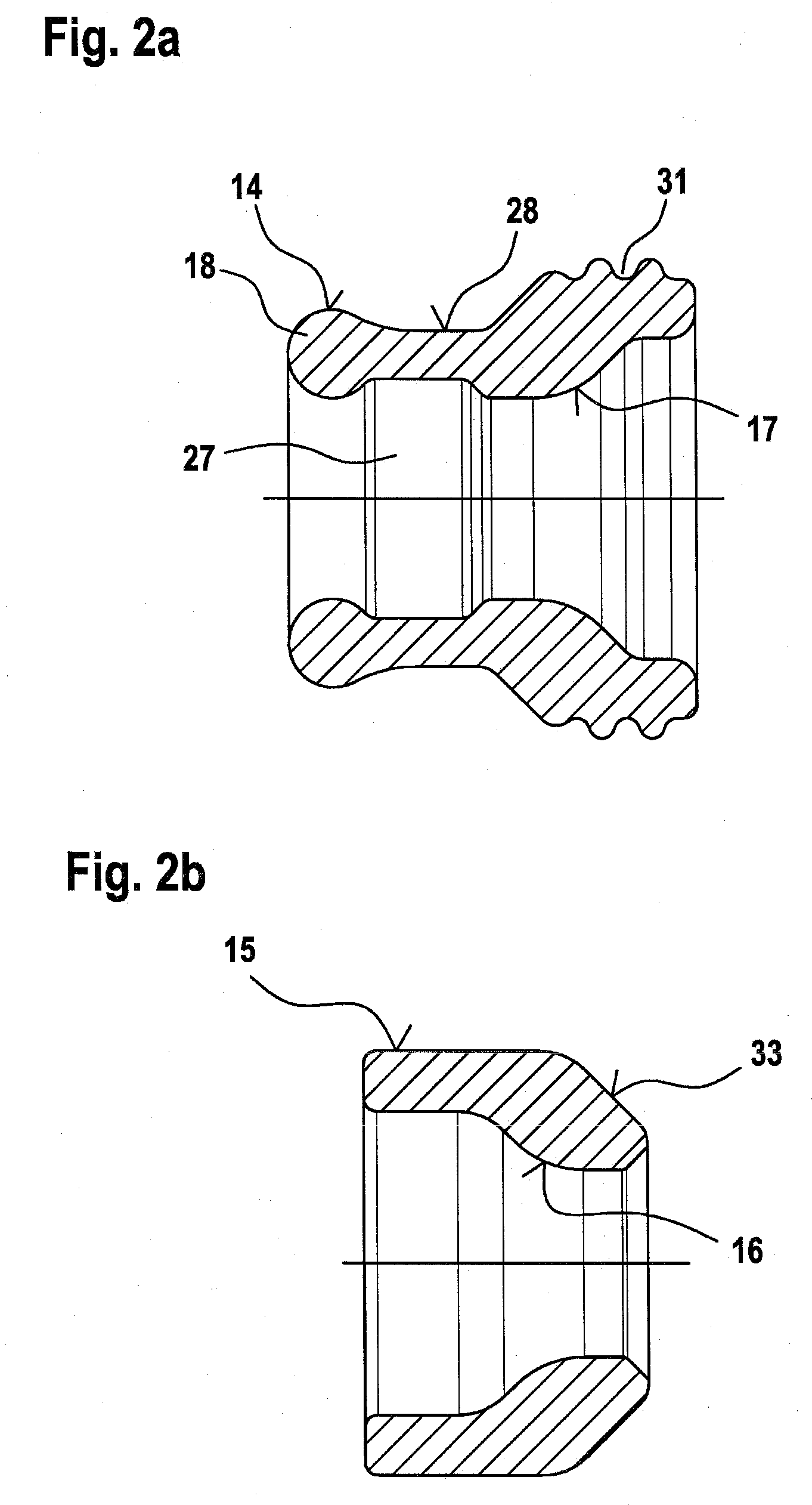

[0015]The percussion bolt 12 is made from solid steel and comprises two elongated cylindrical end parts 21a, 21b, as well as a radially thickened middle part 22 that connects the two end parts 21a, 21b and is located between them.

[0016]The percussion bolt guide 11 extends over the entire length of the percussion bolt 12 and includes a hammer barrel 23, which is braced in the axial direction in a housing 24 of the drill ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com