Heat Exchanger Plate and a Plate Package

a technology of heat exchanger plate and plate package, which is applied in indirect heat exchangers, laminated elements, light and heating apparatus, etc., can solve the problems of deteriorating affecting the efficiency of plate heat exchanger, and affecting the distribution area, so as to achieve the effect of improving the distribution area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

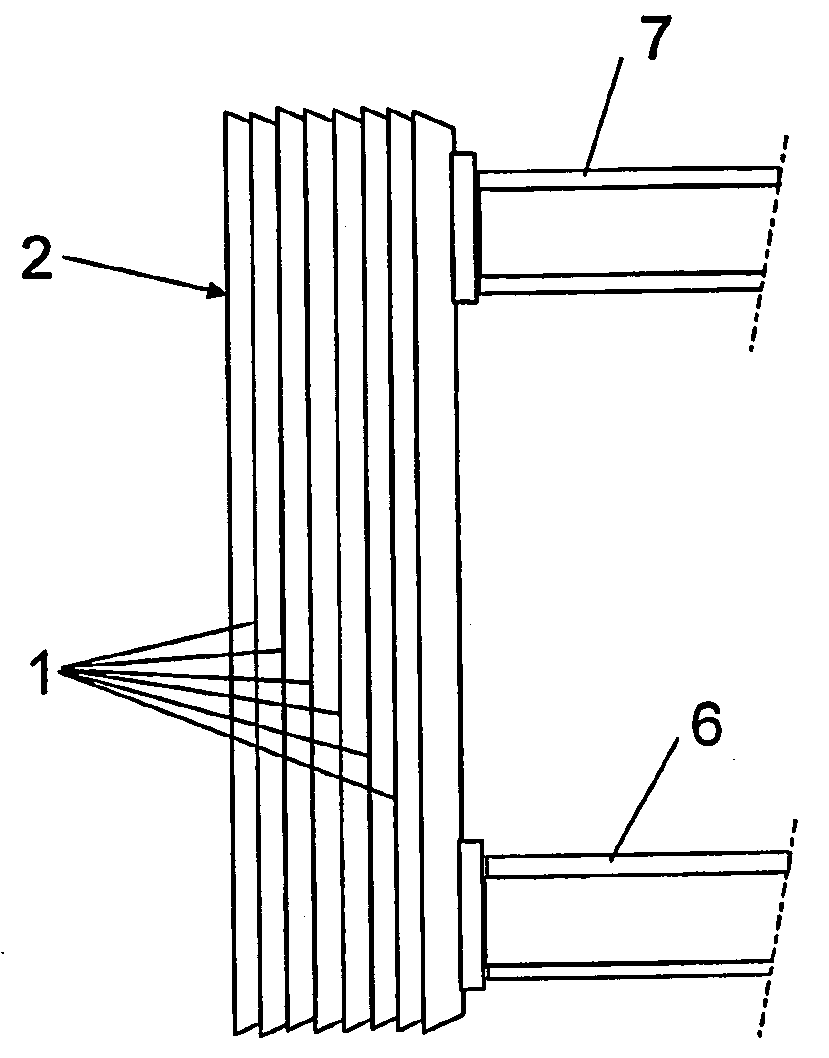

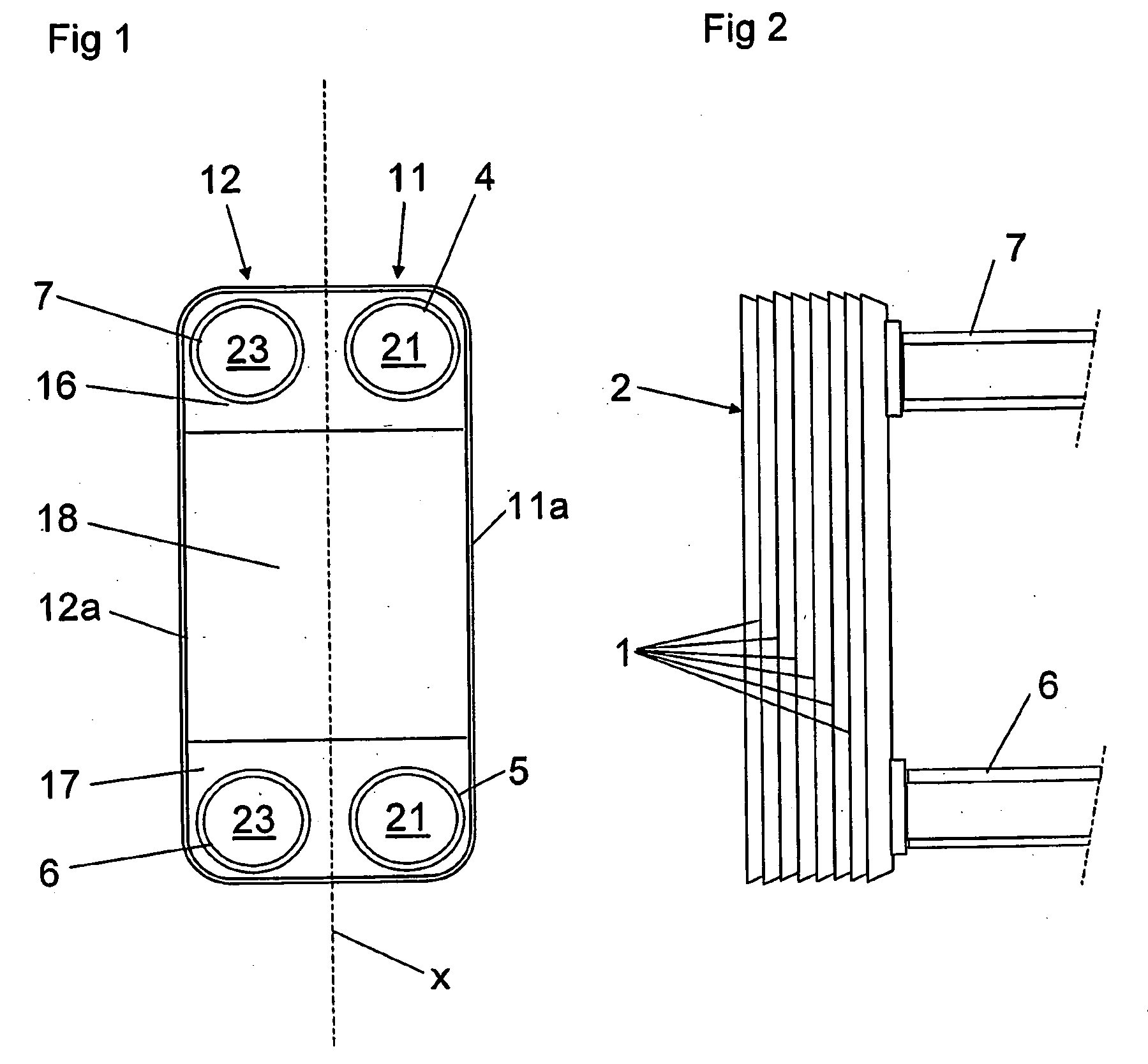

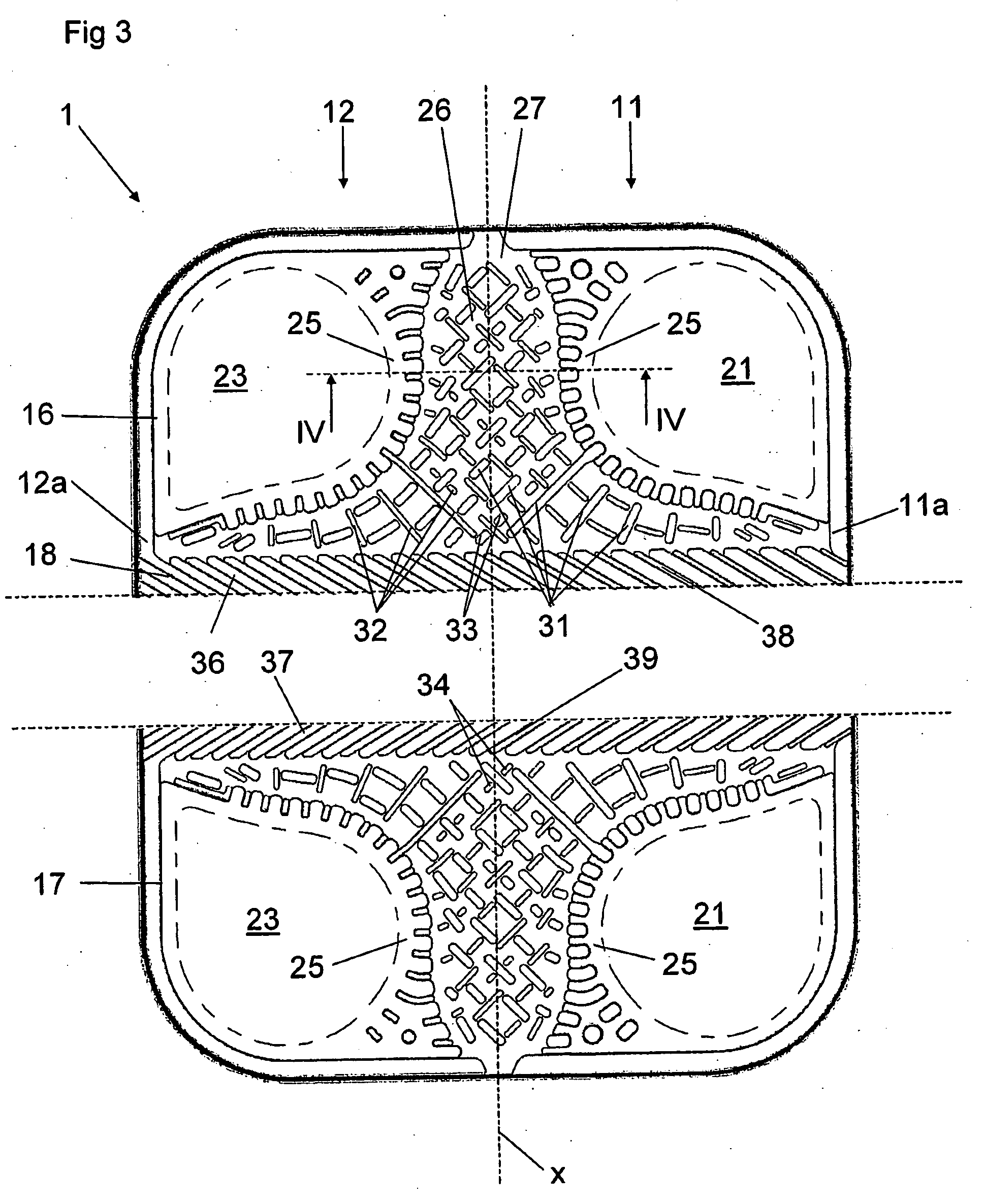

[0029]FIGS. 1 and 2 disclose schematically a plate heat exchanger according to a first embodiment of the invention. The plate heat exchanger includes a number of heat exchanger plates 1, see FIG. 3, which are arranged beside each other in such a way that they form a plate package 2. In the first embodiment, the heat exchanger plates 1 in the plate package 2 are permanently joined to each other through for instance brazing in a manner known per se. The plate heat exchanger includes a first inlet port 4 and a first outlet port 5 for a first medium, and a second inlet port 6 and a second outlet port 7 for a second medium.

[0030]Each heat exchanger plate 1 has in the embodiment disclosed a substantially rectangular basic shape and extends between a primary edge zone 11a and a secondary edge zone 12a in parallel with a central extension plane 13, an upper plate plane 14 and a lower plate plane 15, see FIG. 4. The central extension plane 13 includes a longitudinal centre axis x which divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com