Solar collector

a solar collector and collector body technology, applied in the field of solar collectors, can solve the problems of increasing the cost associated with the burning of fossil fuels, the economic viability of such systems is not helped by metal prices, and the system is not used extensively, so as to reduce the temperature of the roof cavity, collect more energy, and reduce the effect of destructive levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

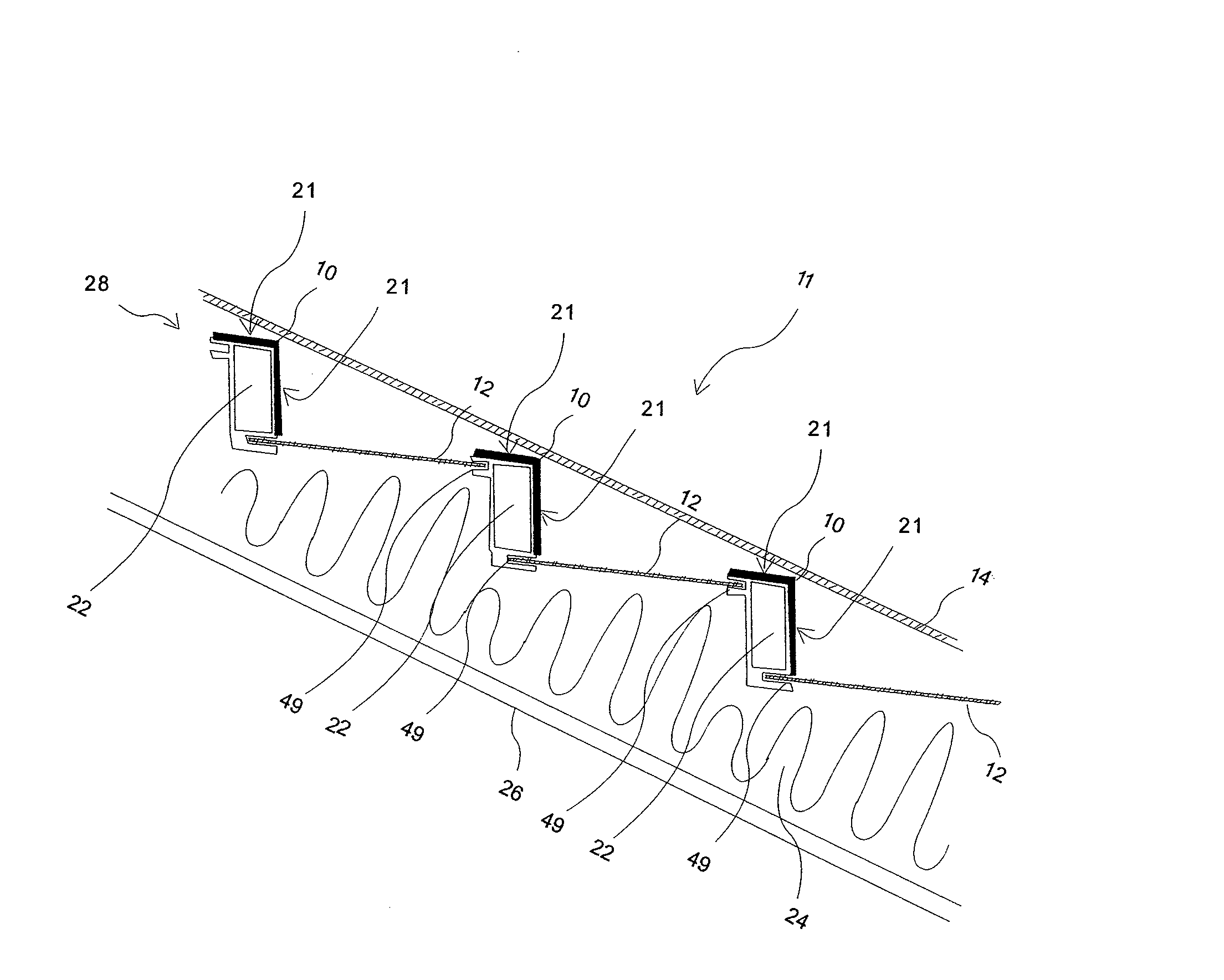

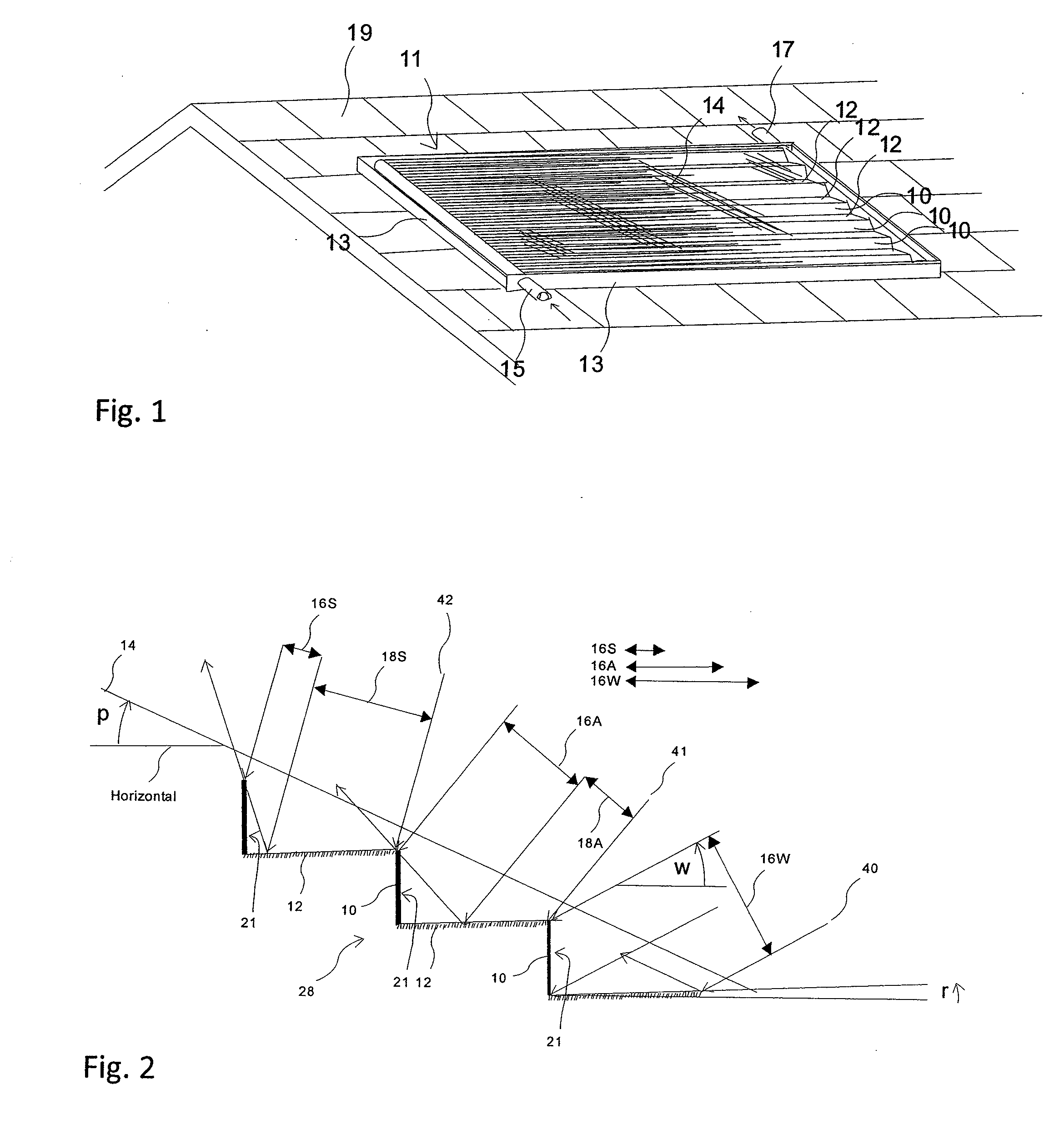

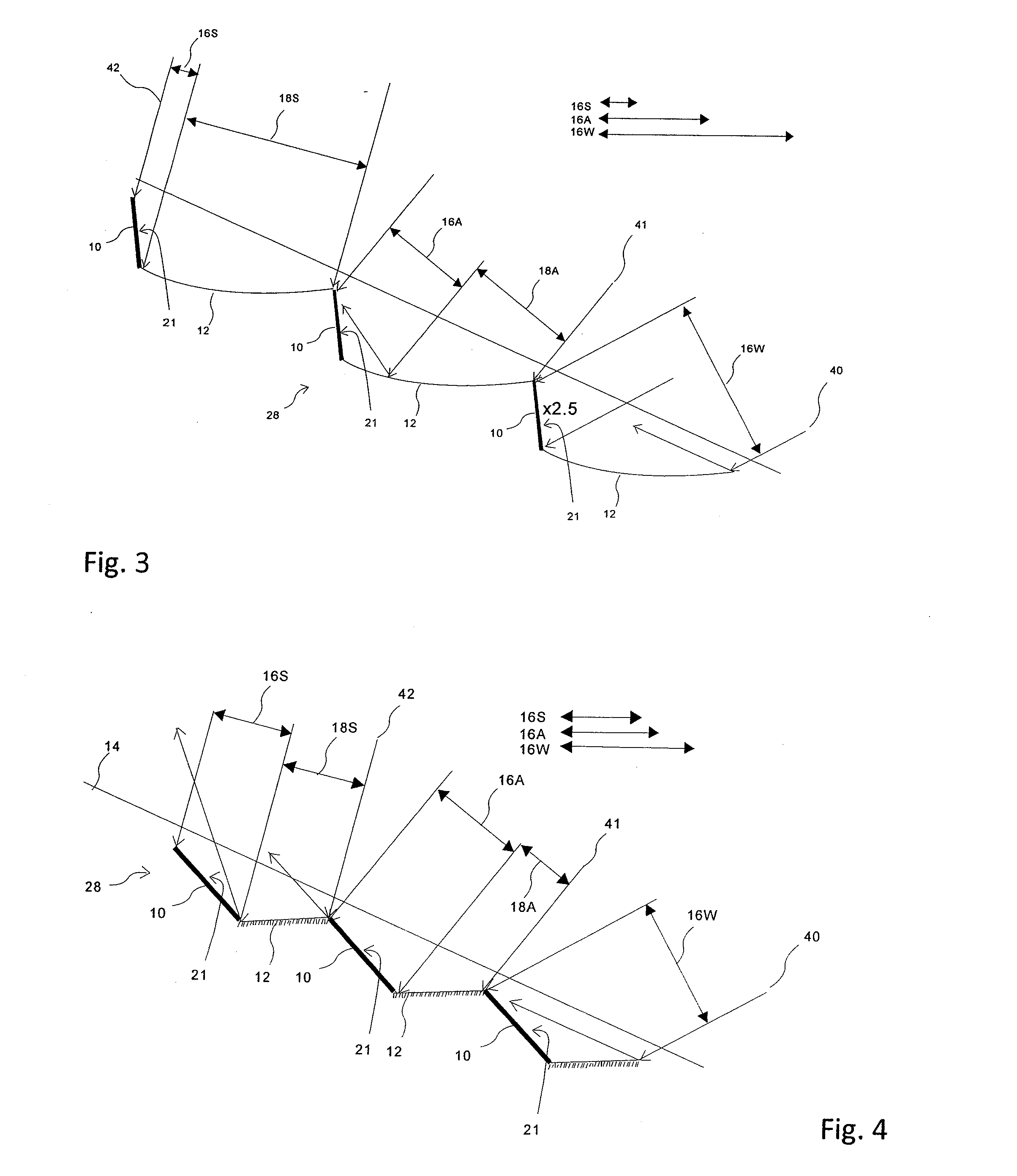

[0060]Referring to FIG. 1 a solar collector 11 is shown fitted to a roof structure 19. Such an installation may be made as a retrofit or may be completed at the time of building in which case the roof may be modified specifically to allow simplified installation and ducting of pipe work. The embodiment shows a solar collector 11 with a typical casing structure including side walls 13, top cover 14, and a bottom cover or wall 26 (ref FIGS. 6-14&16), with an internal arrangement of absorber elements 10 and reflectors 12 configured in a step-like structure. Inlet 15 and outlet 17 end piping connections are provided for the absorber fluid channels 22 (ref FIGS. 6-15). Piping (not shown) connected to the inlet 15 and outlet 17 will be lead from the roof 19 and connected to a heat storage system or used directly for the provision of useful heat.

[0061]The preferred solar collector 11 is a low profile panel which absorbs solar energy and converts it to heat. A passive or non-mechanical meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com