Control apparatus for an internal combustion engine

a control apparatus and internal combustion engine technology, applied in the direction of electric control, machines/engines, instruments, etc., can solve the problems of reducing the control accuracy the response time of the actual phase angle becomes relatively long, and the control delay time until the start of operation of the valve timing variable mechanism might be extended, so as to reduce the response time of the actual engine operating characteristic, shorten the control delay time, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

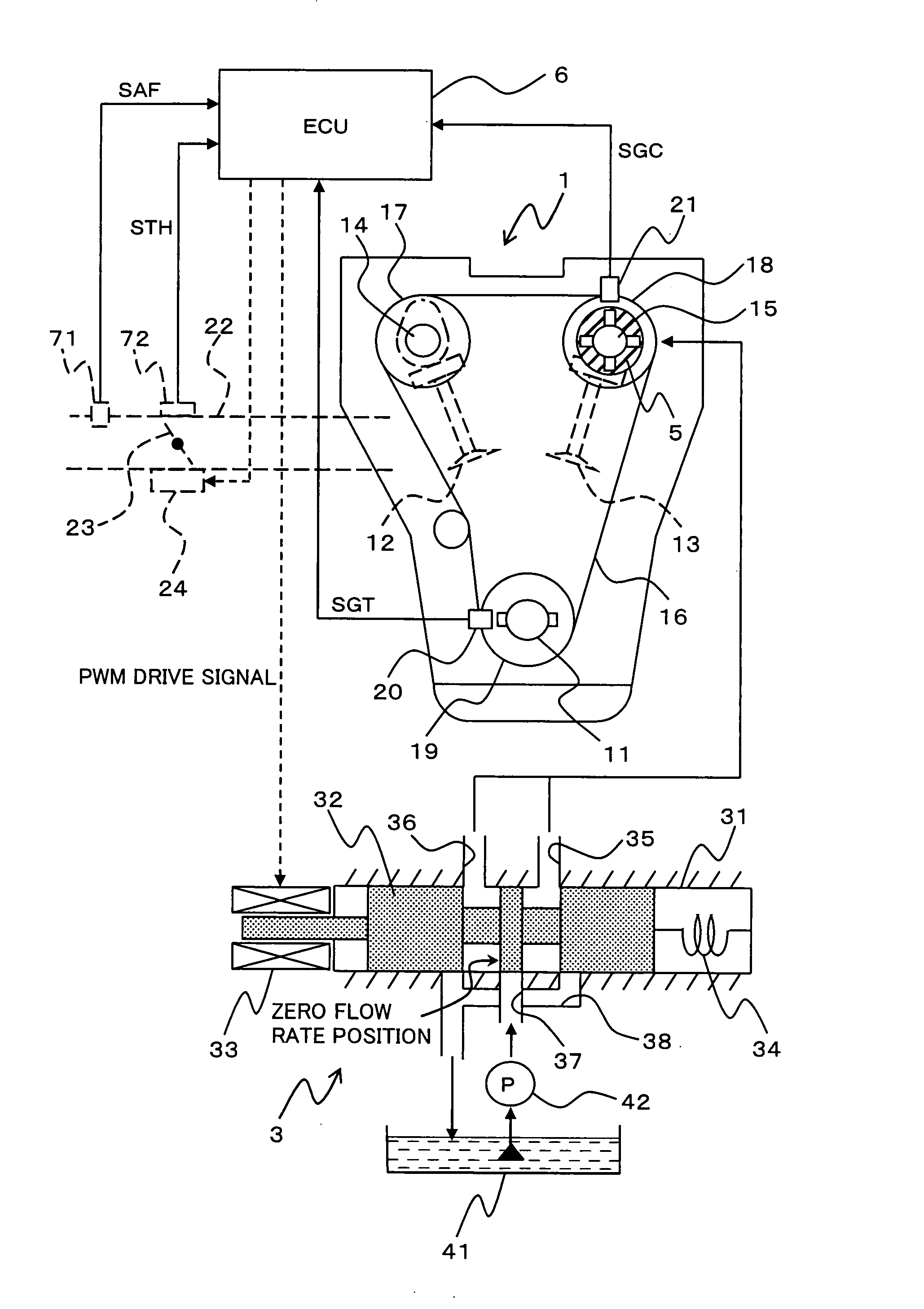

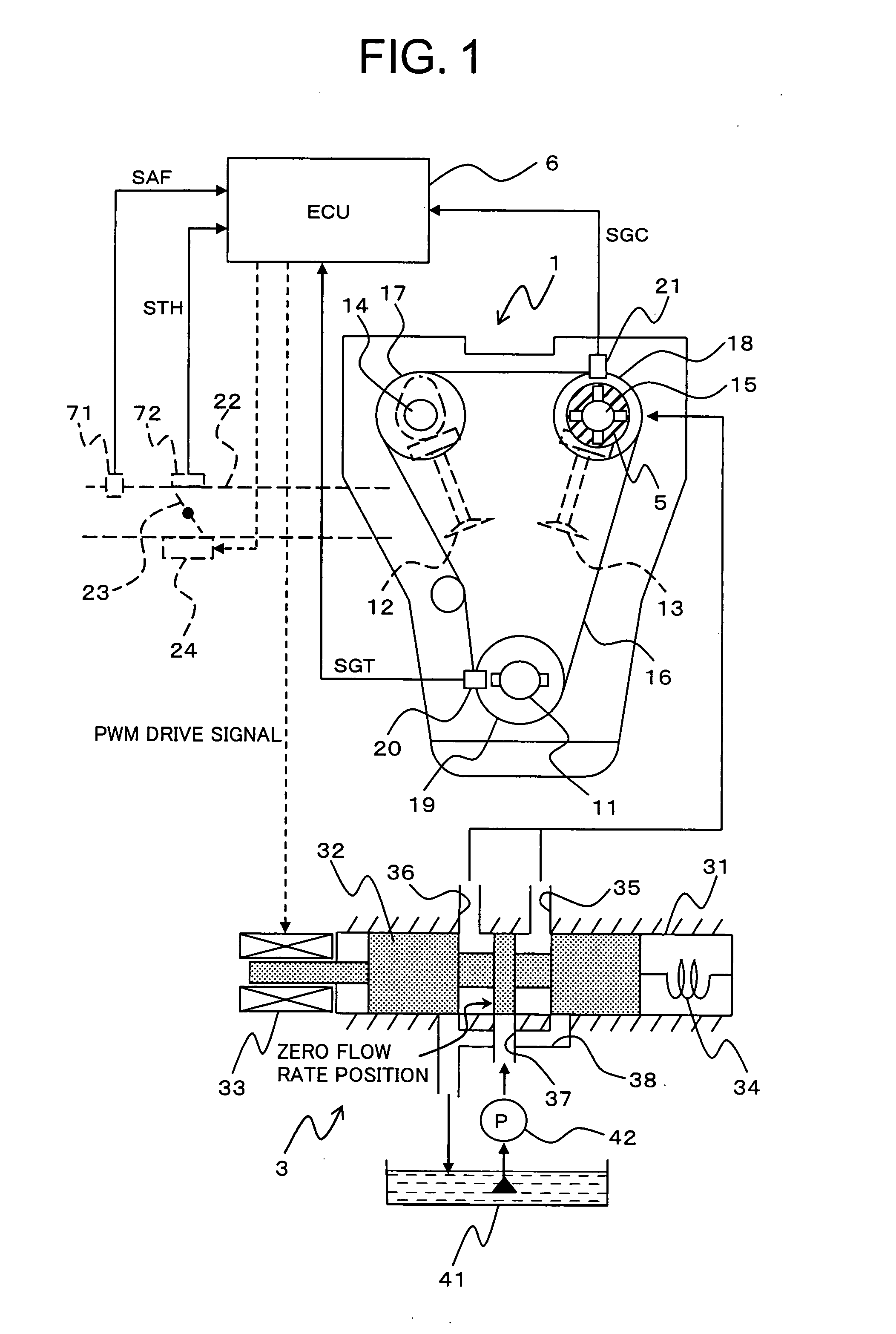

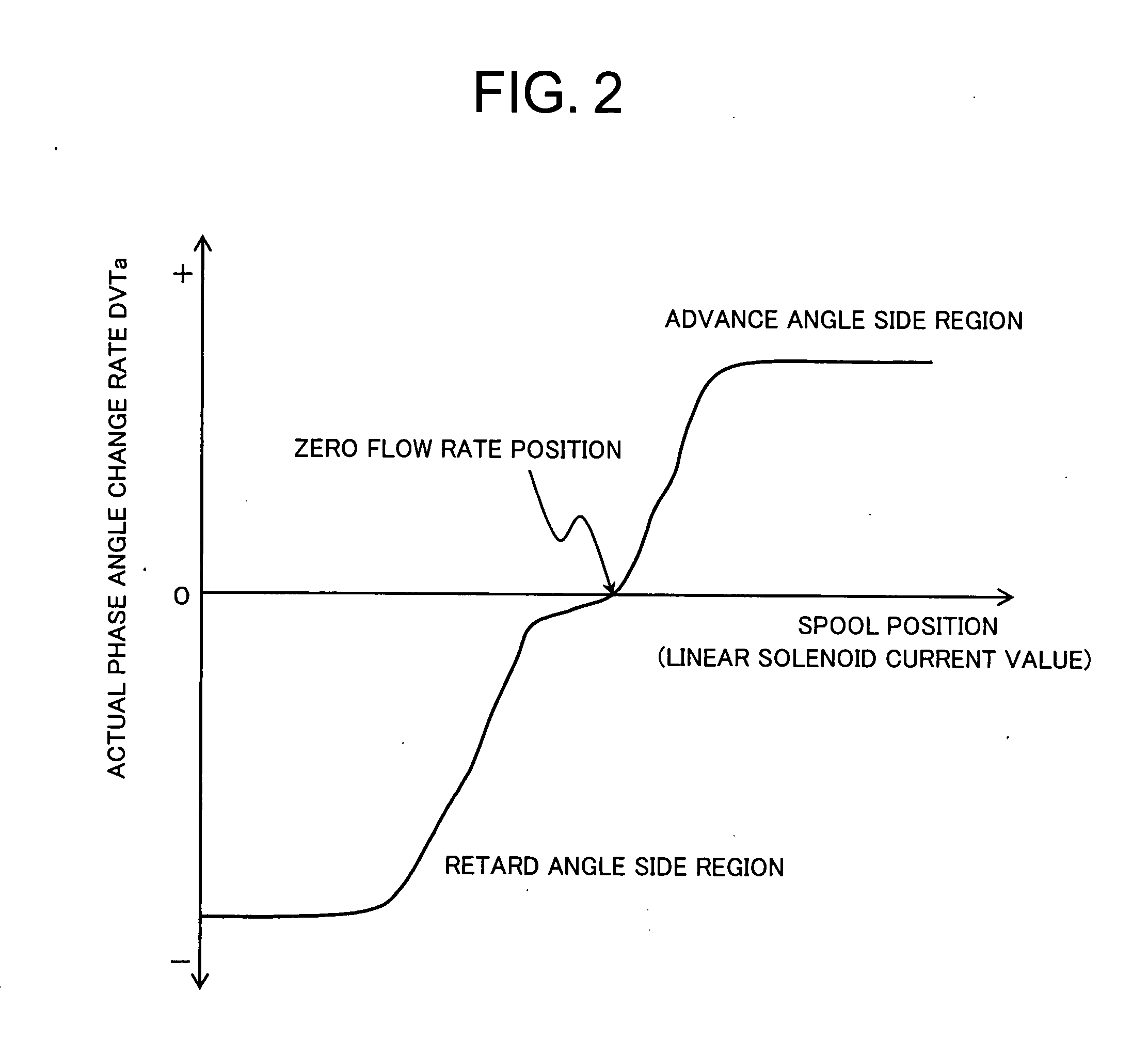

[0041]Referring to the drawings and first to FIG. 1, therein is shown an entire system including a control apparatus for an internal combustion engine according to a first embodiment of the present invention.

[0042]In FIG. 1, an internal combustion engine 1 has a combustion chamber (not shown) defined by a tubular cylinder (not shown) and a piston that is connected with a crankshaft 11, wherein a mixture having fuel and air mixed with each other is sucked into the combustion chamber so as to be combusted therein.

[0043]The cylinder is provided with an intake valve 12 for opening and closing an intake passage 22 leading to the combustion chamber, and an exhaust valve 13 for opening and closing an exhaust passage (not shown) leading to the combustion chamber.

[0044]At an upstream side of the intake passage 22, there is arranged an air flow sensor 71 (i.e., an operating condition detection section and an actual operating characteristic detection section) that serves to detect an actual am...

embodiment 2

[0168]In the above-mentioned first embodiment, the phase angle feedback control section 67 calculates the amount of operation Dout with respect to the linear solenoid 33 of the OCV 3 by using the PID control gains (the proportional gain Kp, the differential gain Kd and the integral gain Ki) which are fixed values, respectively, but the present invention is not limited to this.

[0169]The phase angle feedback control section 67 may execute the phase angle feedback control by switching among the PID control gains in accordance with the phase angle deviation EP (operating characteristic deviation) between the target phase angle VTt and the actual phase angle VTa.

[0170]Also, the phase angle feedback control section 67 may execute the determination of stopping the phase angle feedback control based on the phase angle deviation EP.

[0171]In the following, reference will be made to the processing of switching among the PID control gains for the phase angle feedback control in accordance with ...

embodiment 3

[0189]Although no mention has been made in the above-mentioned first and second embodiments, the phase angle feedback control section 67 may execute a filter calculation with respect to the actual phase angle VTa detected by the actual phase angle detection section 65 with the use of a filter constant that is variably set in accordance with the crank angle signal period Tsgt.

[0190]In the following, reference will be made to the processing of executing the filter calculation with respect to the actual phase angle VTa with the filter constant that is variably set in accordance with the crank angle signal period Tsgt.

[0191]The configuration or construction of a control apparatus for an internal combustion engine according to a third embodiment of the present invention is the same as that of the above-mentioned first embodiment, and hence a detailed explanation thereof is omitted.

[0192]Note that an explanation is omitted here about the operation of this third embodiment similar to that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com