Diamond Cutting Tool and Manufacturing Method Thereof

a cutting tool and diamond technology, applied in the direction of grinding devices, superimposed coating processes, instruments, etc., can solve the problems of diamond particles moving in disarray, so much plating time in order to thicken the plating thickness, and increase the manufacturing cost and time, so as to achieve the effect of shortening the manufacturing tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

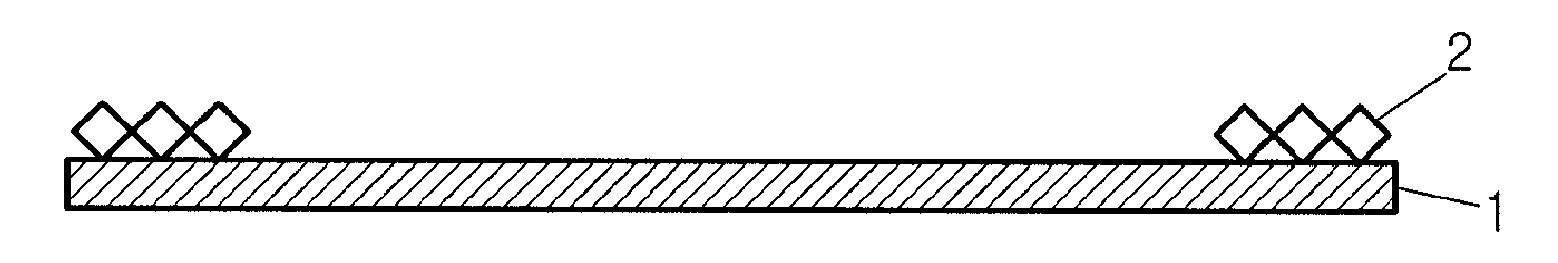

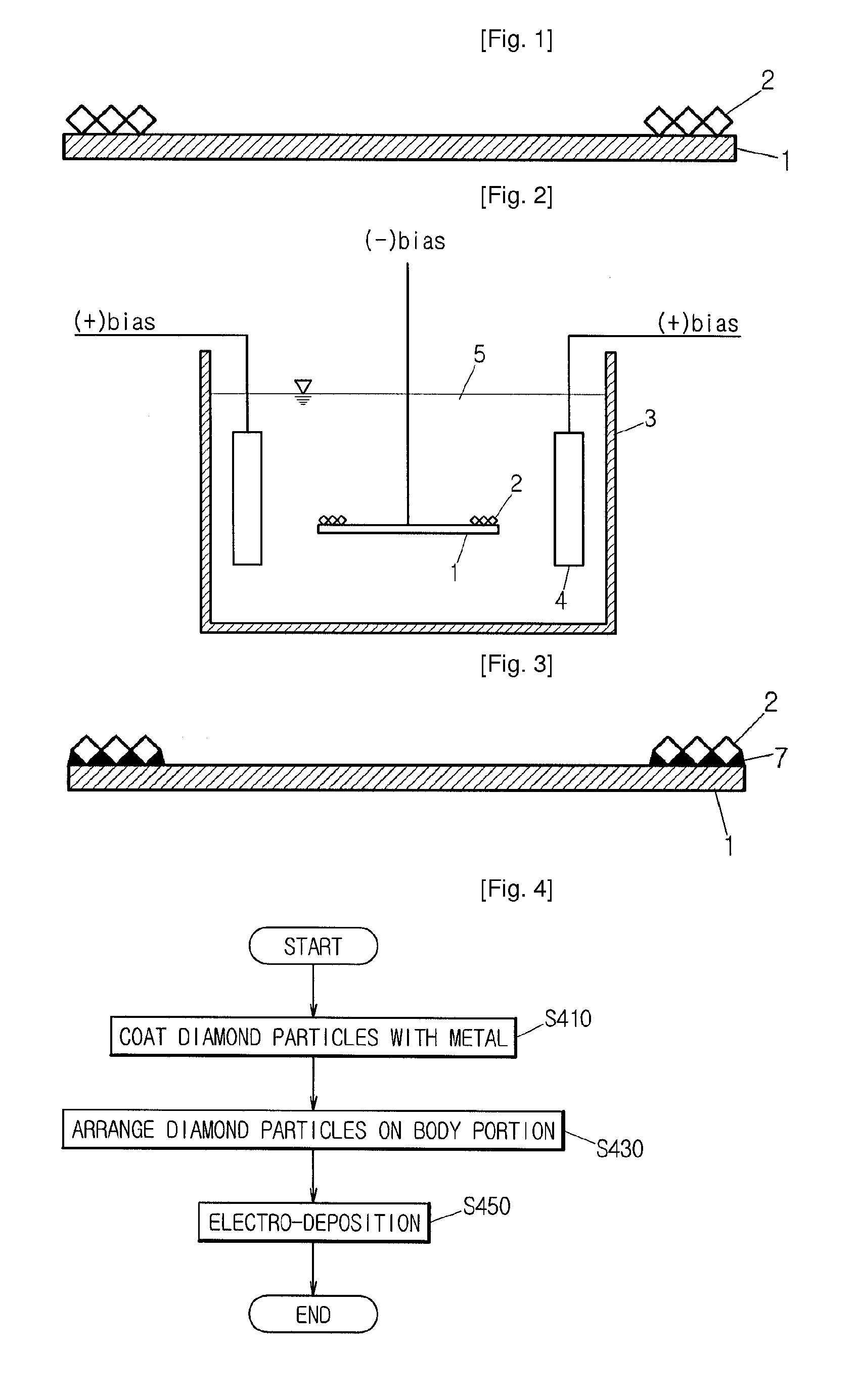

[0031]FIG. 4 is a flow chart showing a manufacturing method for a diamond cutting tool according to a preferred embodiment of the present invention. As shown in FIG. 4, the manufacturing method for a diamond cutting tool according to the present invention comprises the steps of coating the diamond particles with metal (S410), arranging the metal coated diamond particles on a body portion (S430), and electro-depositing the diamond particles on the body portion (S450).

[0032]Description will be made in detail to the steps of the manufacturing method for the diamond cutting tool according to the present invention.

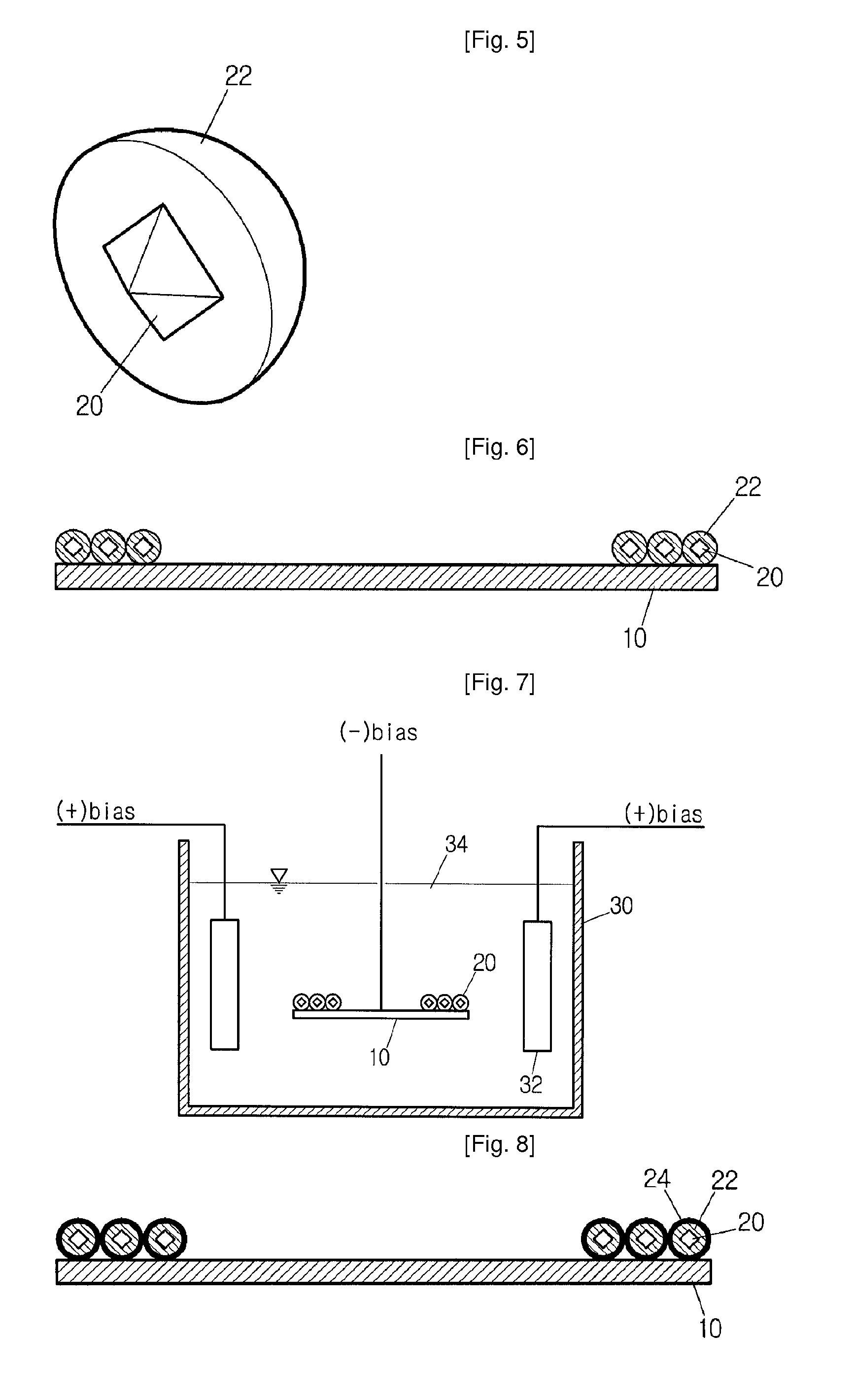

[0033]FIG. 5 is a perspective view of a diamond particle 20 coated with metal 22. As shown in FIG. 5, for manufacturing the diamond cutting tool, a worker first coats the outer surfaces of the diamond particles 20 with metal to form a metal coating lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic property | aaaaa | aaaaa |

| magnetic force | aaaaa | aaaaa |

| magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com