Perpendicular magnetic recording medium with multilayer recording structure including intergranular exchange enhancement layer

a multi-layer recording and magnetic recording technology, applied in the field of perpendicular magnetic recording media, can solve the problems of high media noise, random shift of readback signal peaks, and increase intrinsic media noise, and achieve the effects of good recording properties, less susceptible to corrosion, and poor corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

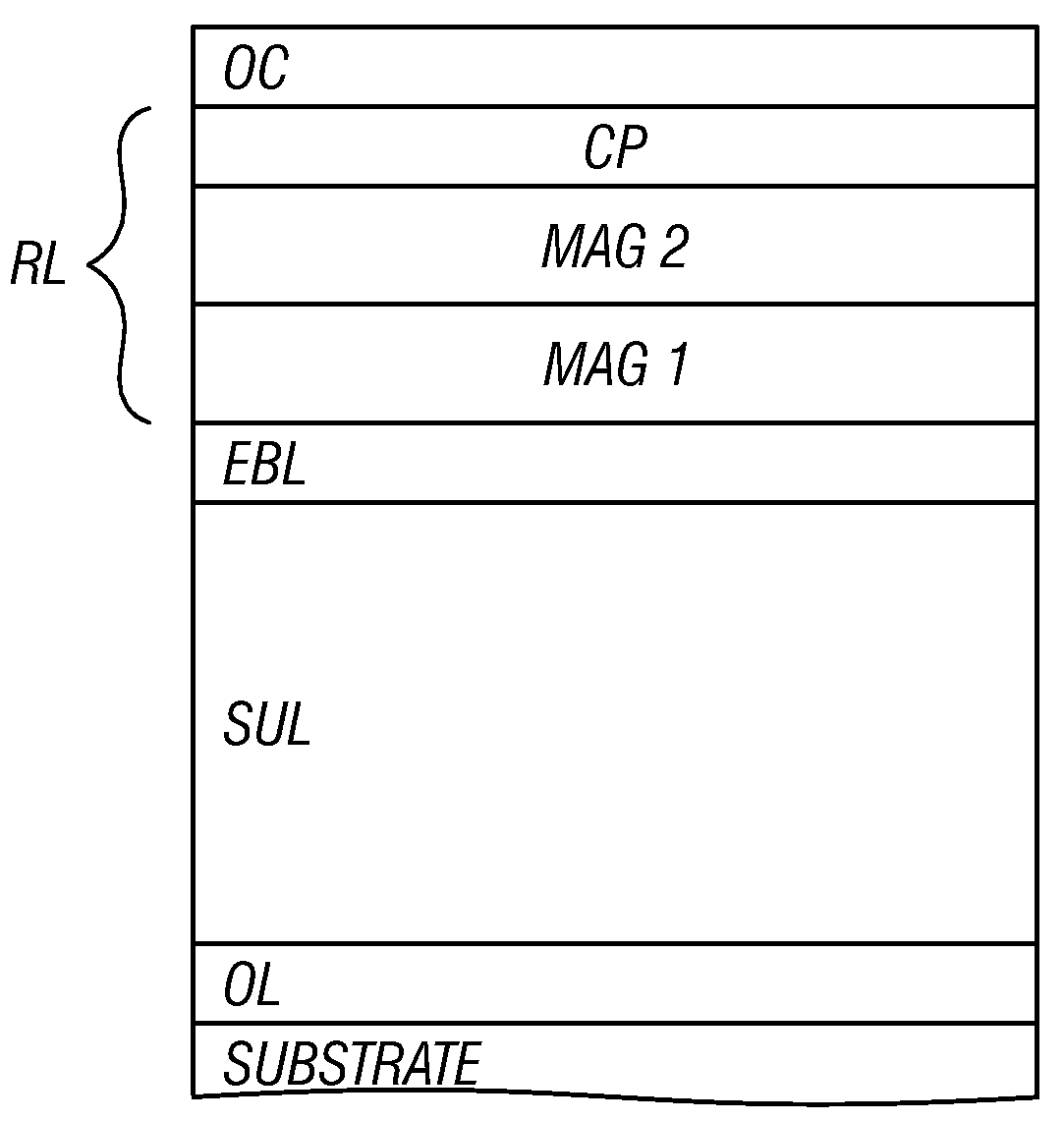

[0028]the perpendicular magnetic recording disk of this invention is illustrated in FIG. 5, which is schematic of a cross-section of the disk. The RL structure is a multilayer of two lower ferromagnetic layers (MAG1 and MAG2), each with reduced or no intergranular exchange coupling, and a CP on top of and in contact with the upper ferromagnetic layer MAG2.

[0029]MAG1 is formed of a granular polycrystalline Co alloy, such as a CoPt or CoPtCr alloy, and an oxide or oxides of Ta. MAG2 is formed of a granular polycrystalline Co alloy, such as a CoPt or CoPtCr alloy, and an oxide or oxides of Si. The CP may be formed of Co, or ferromagnetic Co alloys, such as CoCr alloys. The Co alloys of the CP may include one or both of Pt and B. The CP is deposited directly on MAG2, with MAG2 being deposited directly on MAG1. MAG1 and MAG2 are sputter deposited at relatively high pressure (e.g., 10-20 mTorr) in the presence of oxygen. Alternatively MAG1 and MAG2 may be sputter deposited from an oxide-c...

second embodiment

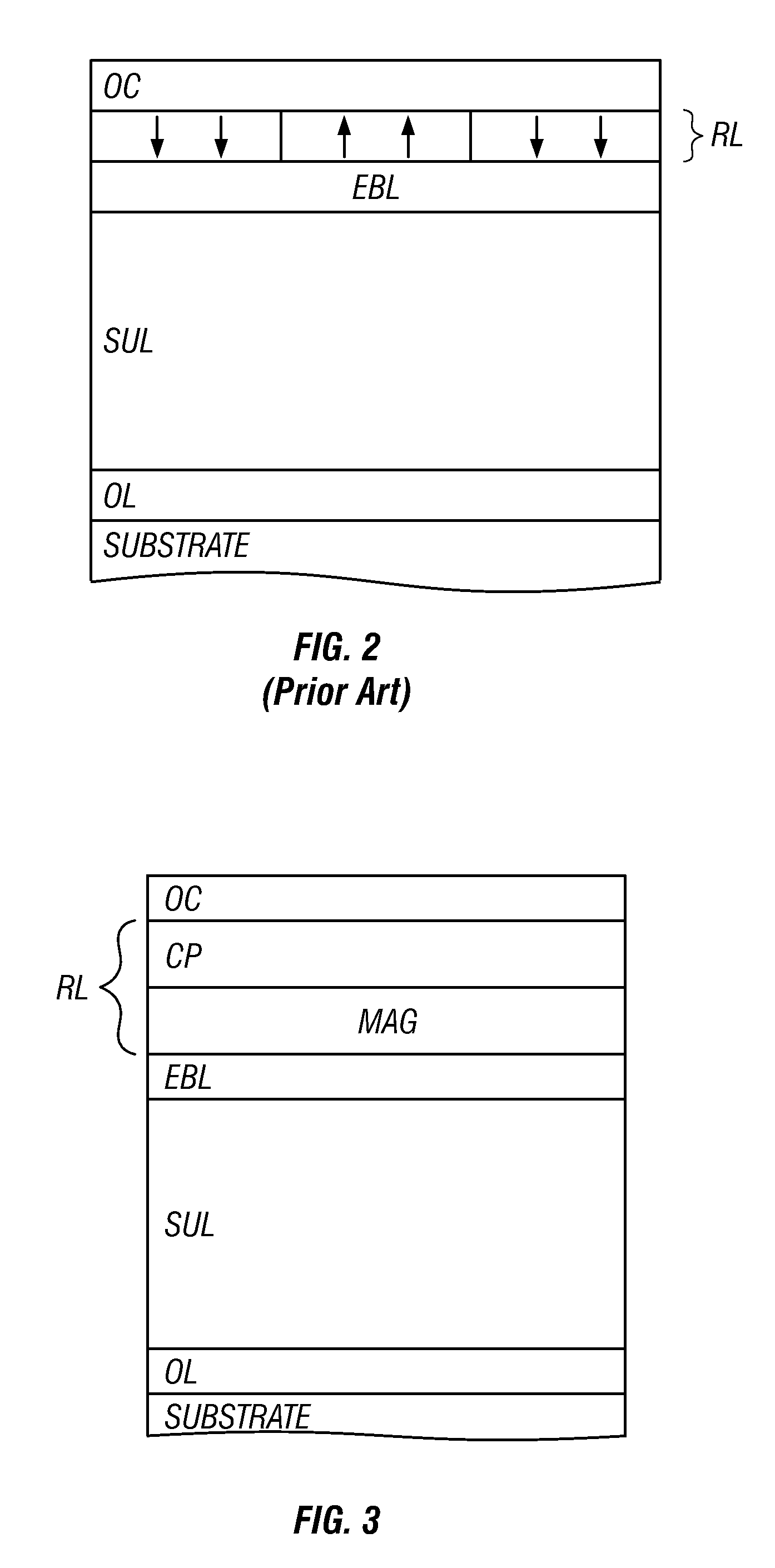

[0032]In the perpendicular magnetic recording medium of this invention, as depicted in FIG. 6, the RL structure is a multilayer with an intergranular exchange enhancement interlayer (IL) in between two ferromagnetic layers, MAG1 and MAG2. The total thickness of MAG1+MAG2 is the same as the thickness of MAG in the prior art of FIG. 3. The IL functions like the CP. However, the intergranular exchange from the IL acts on two interfaces instead of one. Also, because the IL is acting on half the thickness of magnetic layer than in the prior art of FIG. 3, it can be made thinner. Therefore, the same or better effects as achieved with the prior art can be achieved with less total thickness for the RL structure.

[0033]In the embodiment of FIG. 6, the MAG1 and MAG2 layers are preferably formed of a granular polycrystalline Co alloy, such as a CoPt or CoPtCr alloy, with a suitable segregant such as an oxide or oxides of one or more of Si, Ta, Ti, Nb, Cr, V and B. Also, like in the embodiment o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com