Heat dissipation module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

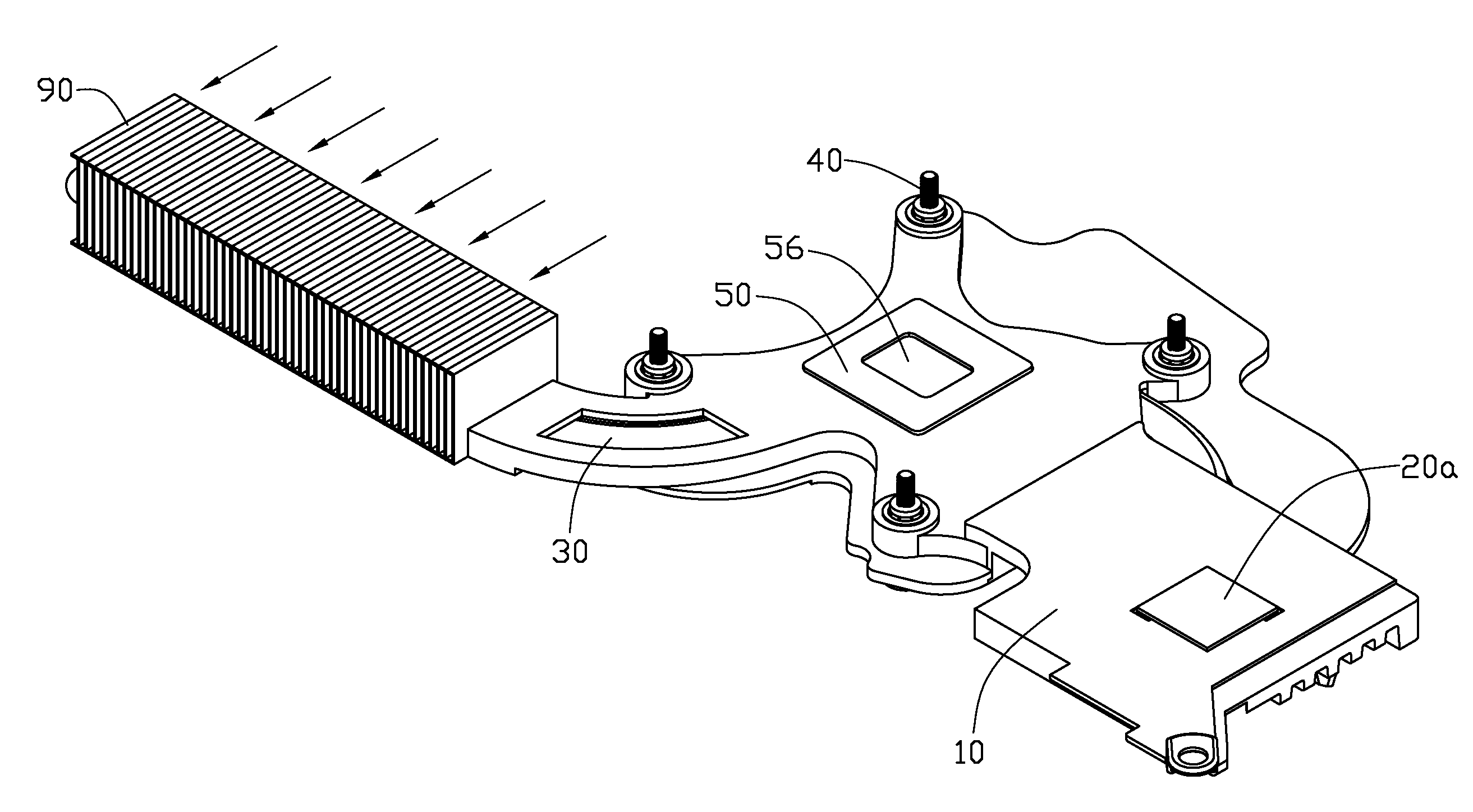

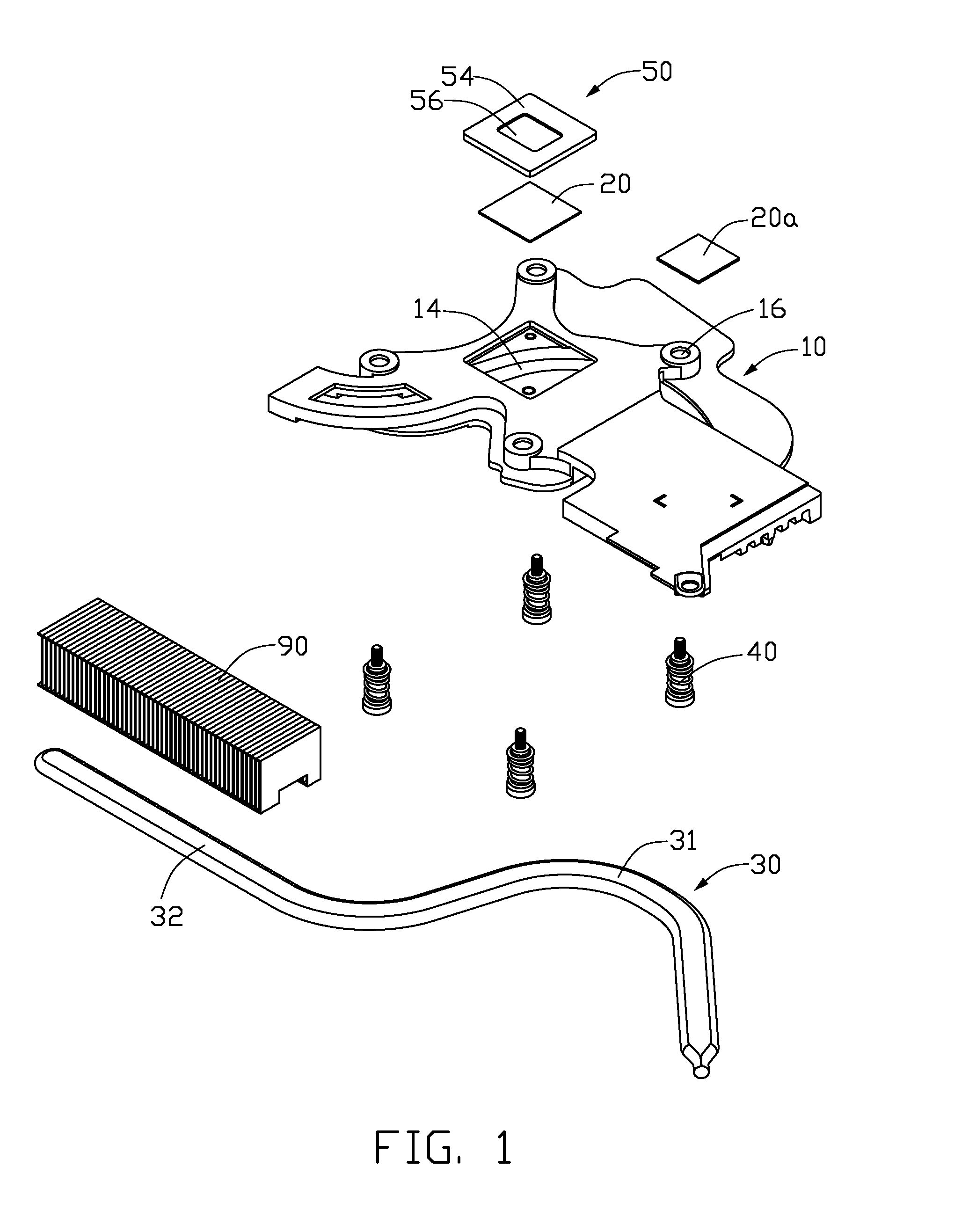

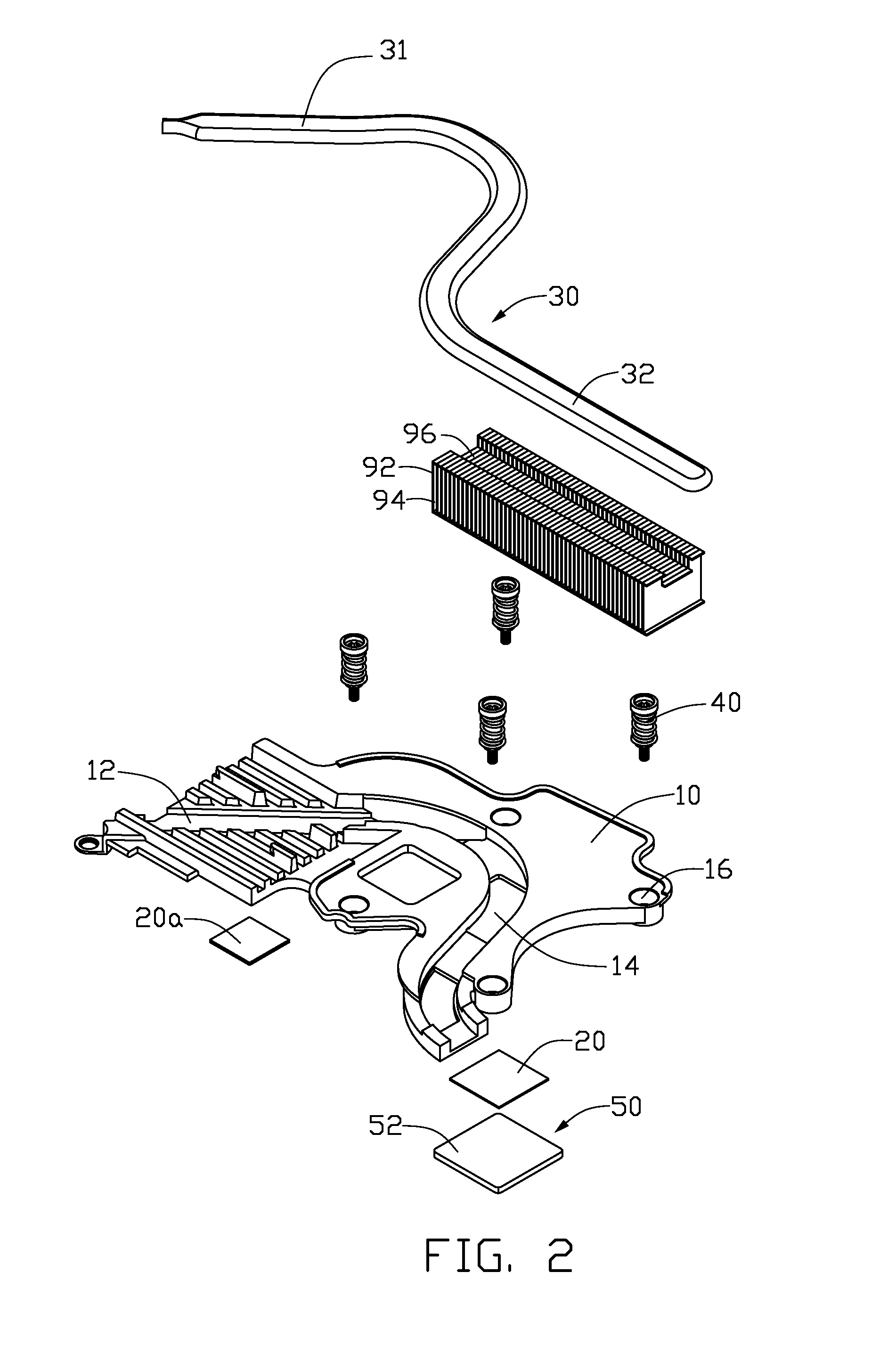

[0017]Referring to FIG. 1, FIG. 2 and FIG. 3, a heat dissipation module in accordance with a preferred embodiment of the present invention comprises a mounting seat 10, a heat pipe 30, a fin unit 90 and a thermal contact block 50.

[0018]A square-shaped receiving groove 14 is defined in a substantially central area of a top side of the mounting seat 10 for receiving the block 50 therein. A plurality of setting holes 16 are defined around the receiving groove 14 for allowing spring-loaded screws 40 to extend therethrough to secure the mounting seat 10 to a mainboard (not shown), such as a circuit board of a notebook computer. An arc-shaped groove 12 is defined in a bottom side of the mounting seat 10 for receiving the heat pipe 30 therein. The receiving groove 14 is connected to and communicates with the groove 12, in a manner such that the heat pipe 30 disposed in the groove 12 can be thermally connected to the block 50 disposed in the receiving groove 14.

[0019]The fin unit 90 compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com