Magnetic annealing tool heat exchange system and processes

a technology of heat exchange system and magnetic annealing tool, which is applied in the direction of magnetic bodies, lighting and heating apparatus, furnaces, etc., can solve the problems of insufficient flexibility to control and vary the heating and cooling steps independently and efficiently, affecting the annealing cycle, and affecting the cooling effect of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

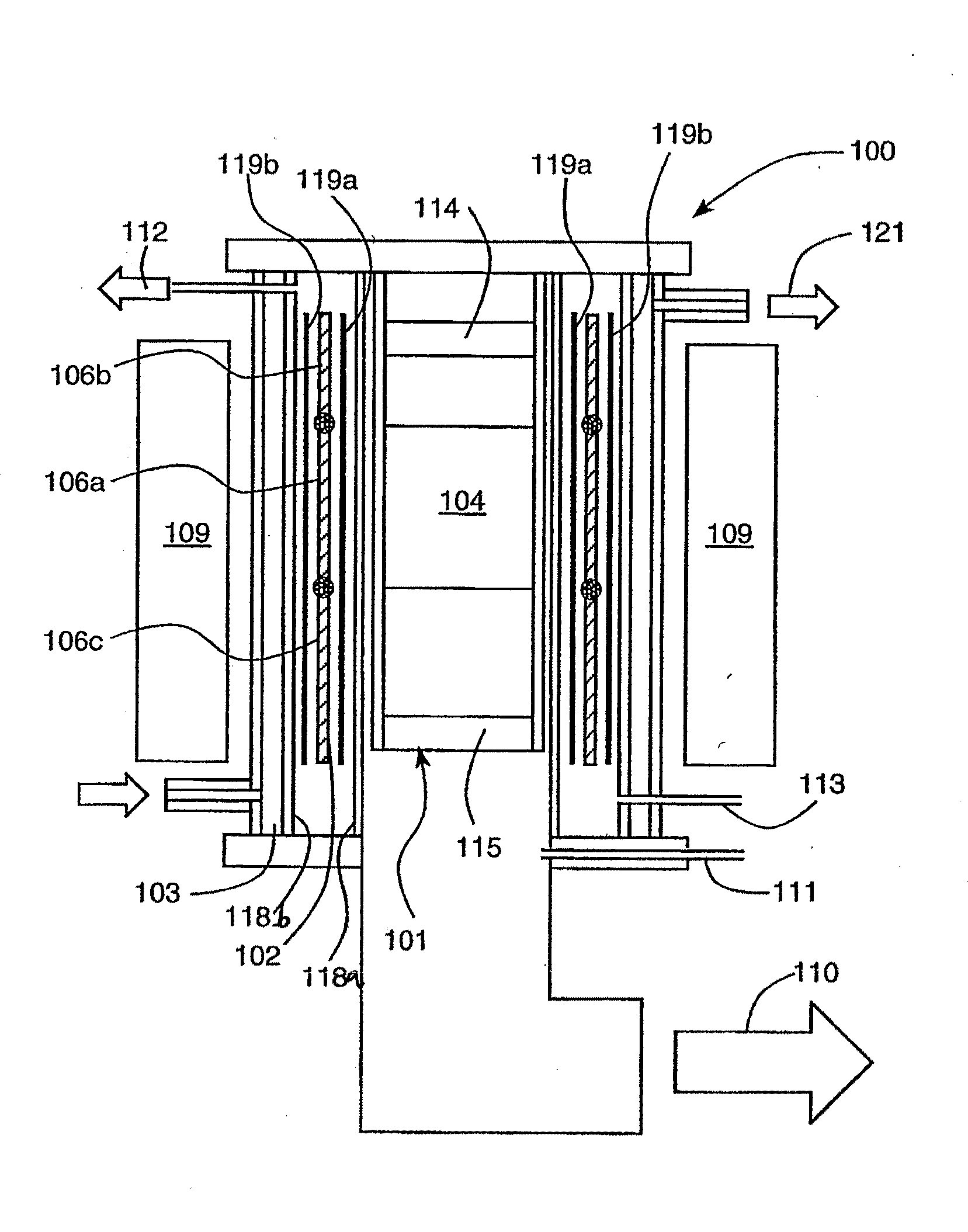

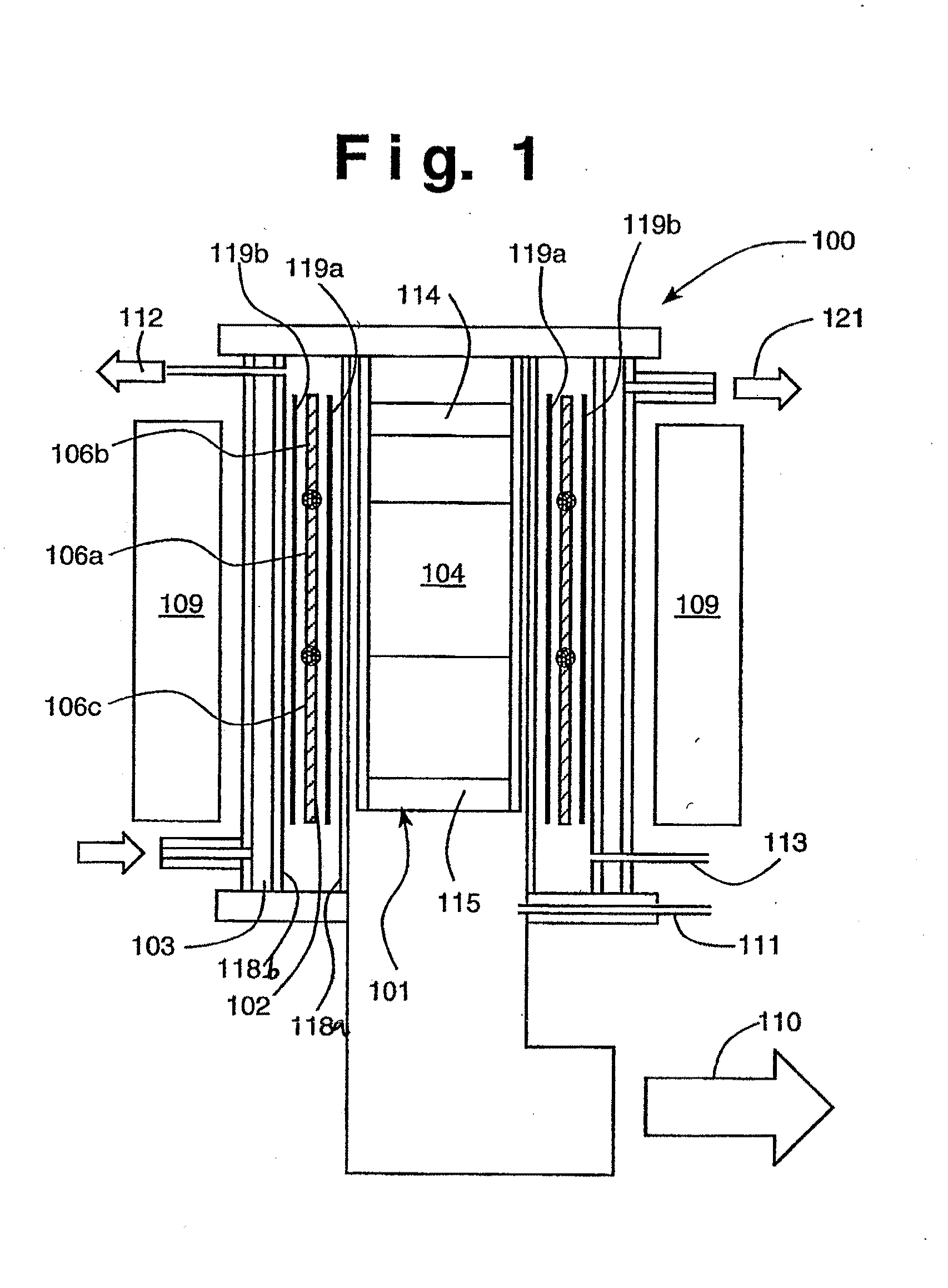

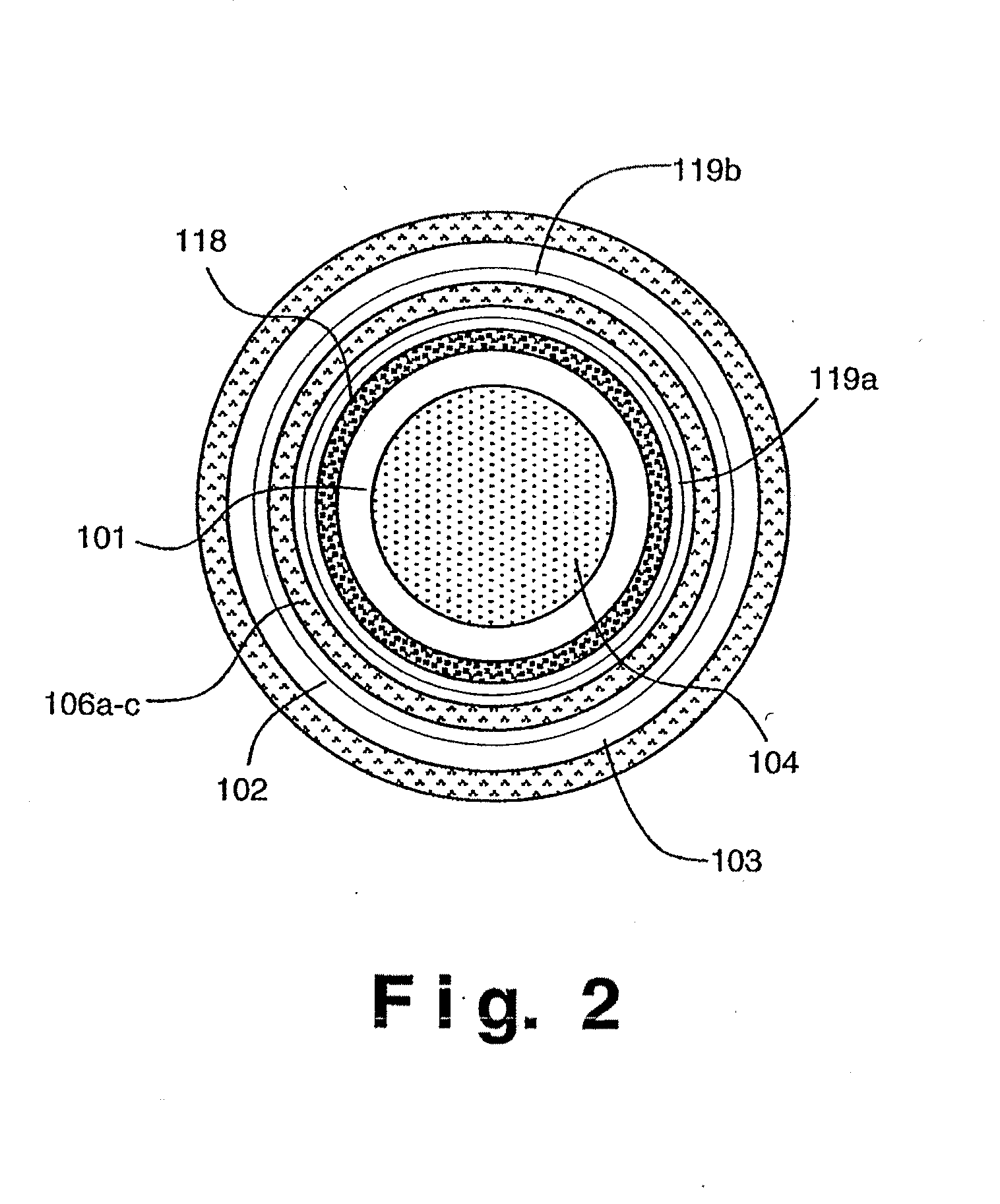

[0059] The particular processes described herein involve utilization of the system of the present invention, wherein an inert or reducing (i.e., non-oxidizing) atmosphere may be introduced to the process chamber at any stage in the anneal cycle / process. For instance, the heating and soaking steps may be carried out in a hard vacuum, while the cooling steps, may be carried out in a soft vacuum, a rough vacuum or a positive pressure (i.e., above 760 Torr) by introducing an inert or reducing atmosphere. The process conditions vary depending on the annealing cycle / process. Temperatures in the process chamber range from 200 to 1000° C., and the pressure will range from a hard vacuum (e.g., 10−7 Torr) to atmospheric conditions (e.g., 760 Torr). The workpieces can be processed in an inert atmosphere, a reducing atmosphere, or a vacuum. The gases employed can be hydrogen, helium, nitrogen, argon or any mixtures therefrom. The gases include in the cooling step (i.e., introduced into the elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com