Molded waveguides

a waveguide and waveguide technology, applied in the direction of circuit masks, chemical vapor deposition coatings, capsule delivery, etc., can solve the problems of limited materials suitable for reactive ion etching masks, difficult to etch relatively precisely, and inability to etch vertical channels,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] U.S. patent application Ser. No. 09 / 634,201, filed Aug. 9, 2000 and U.S. patent application Ser. No. 09 / 004,583, filed Jan. 8, 1998 (now U.S. Pat. No. 6,355,198) and U.S. application Ser. No. 08 / 616,929, filed Mar. 15, 1996 and U.S. provisional application Ser. No. 60 / 046,689 filed May 16, 1997, all are incorporated herein by reference.

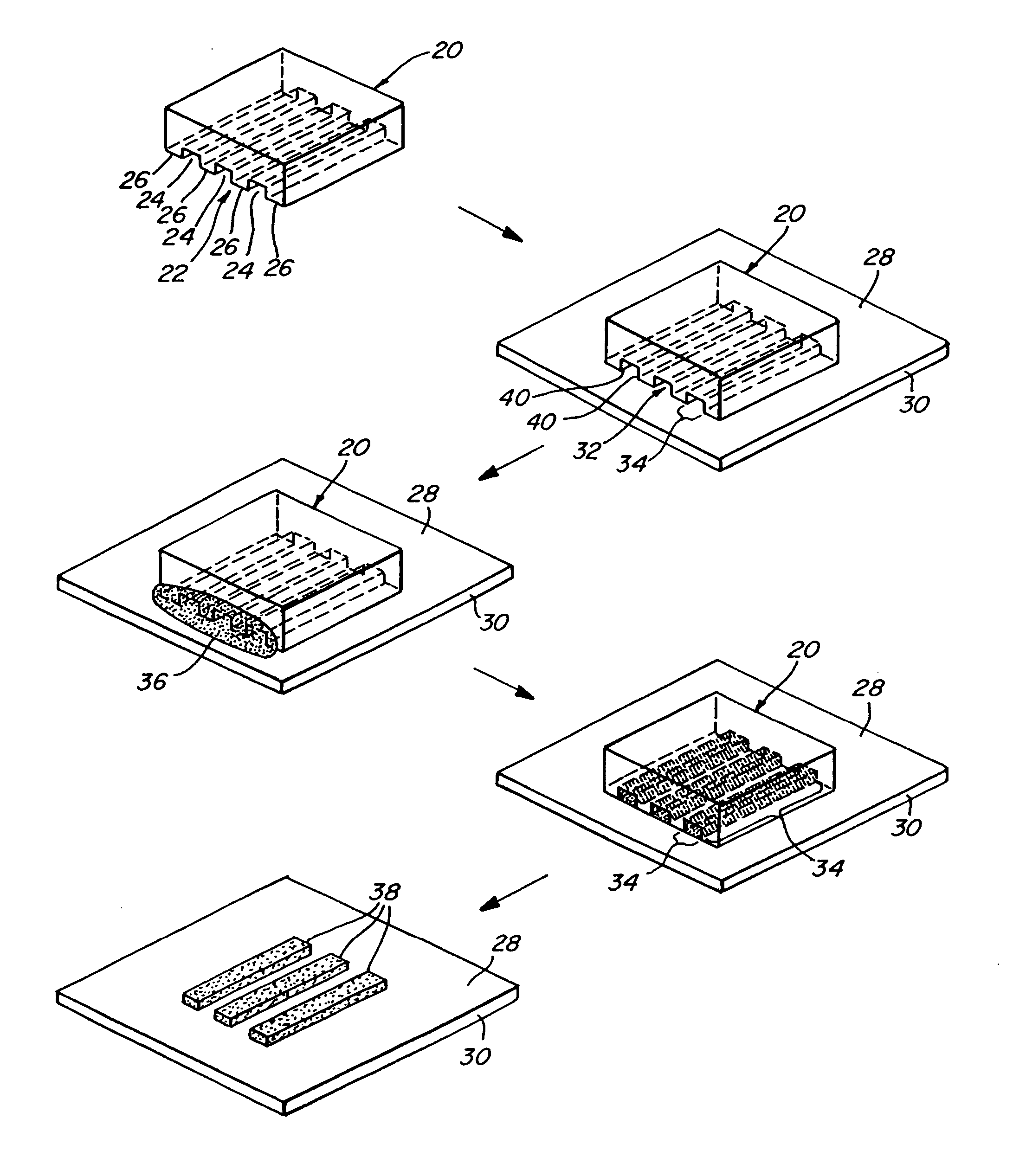

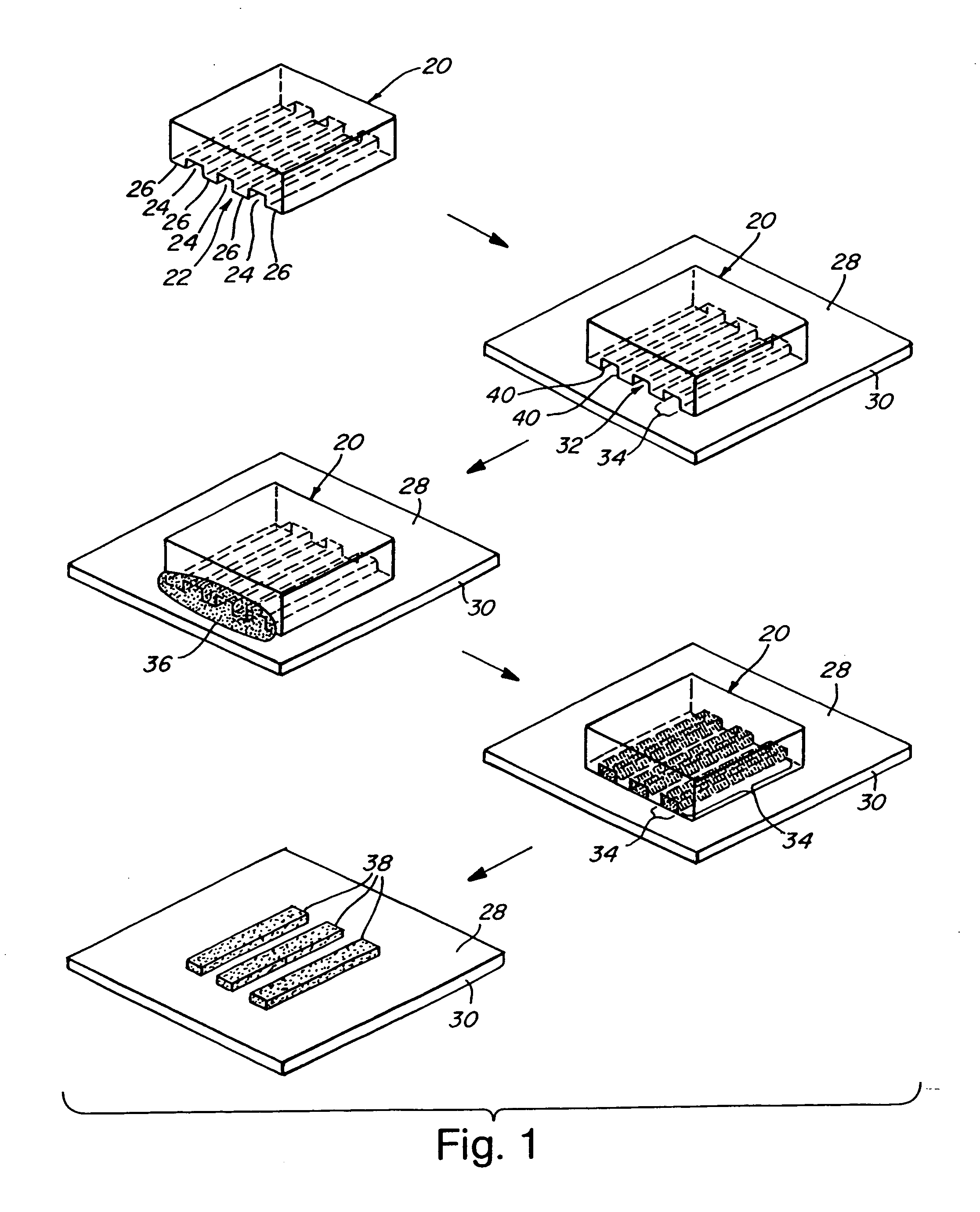

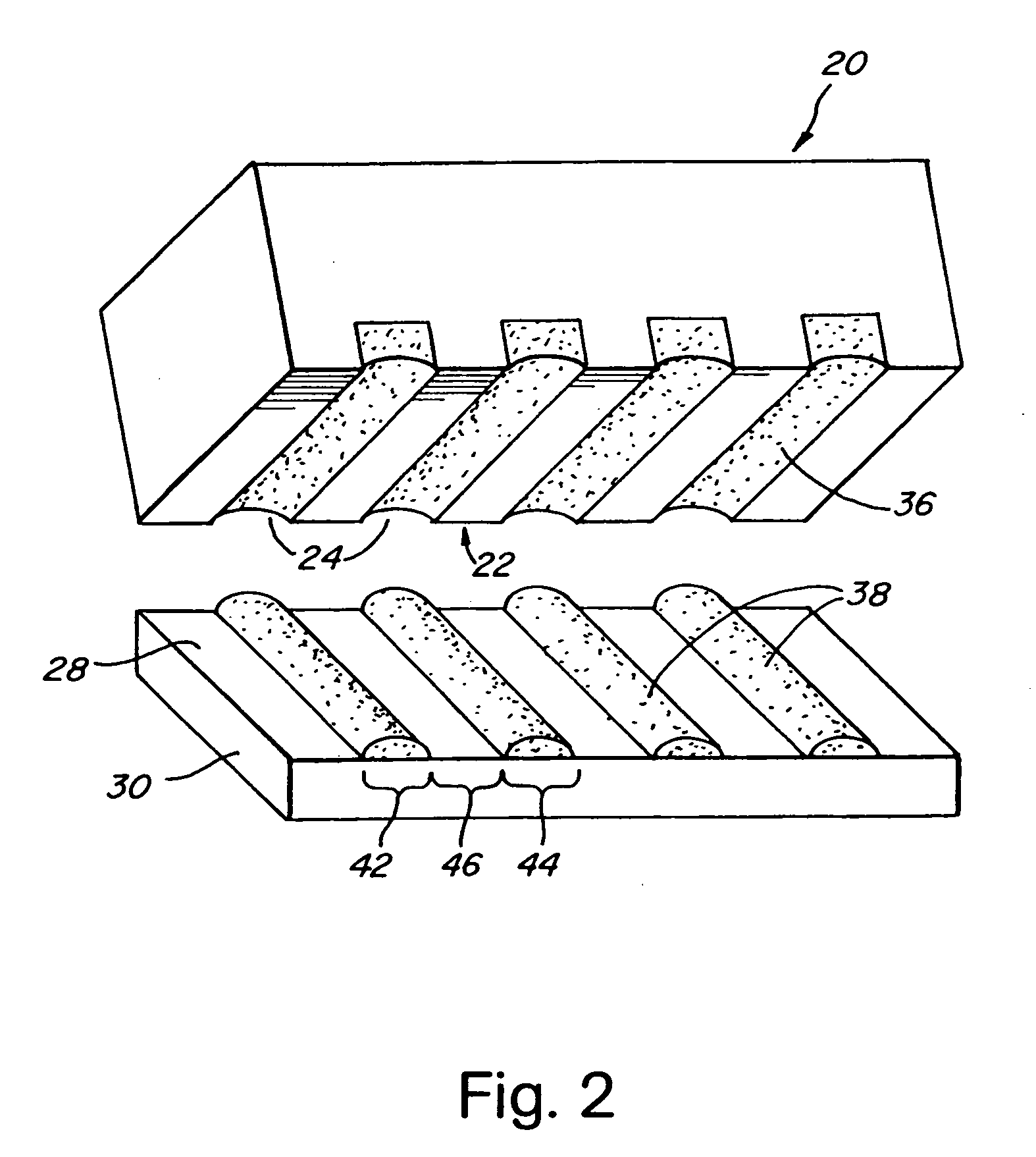

[0070] The present invention provides, in one aspect, techniques for placement, at regions proximate a substrate surface, of chemically or biochemically active agents, fluid precursors of articles such as waveguides to be immobilized proximate a substrate surface, and / or other species desirably transferred to a region or regions proximate a substrate surface in a pattern. “Fluid precursor”, as used herein, means a material that is fluid enough that it can be formed into a pattern using a forming article, using techniques described herein. The invention utilizes an applicator having a pattern of indentations that can be used to transfer such a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com