Method for Preparing Nano Metallic Particles

a nano-metal and nano-particle technology, applied in the direction of magnetic bodies, superimposed coating processes, transportation and packaging, etc., can solve the problems of complex fabrication process, and the array of nano-metal particles, so as to achieve high fabrication and time costs and lower costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

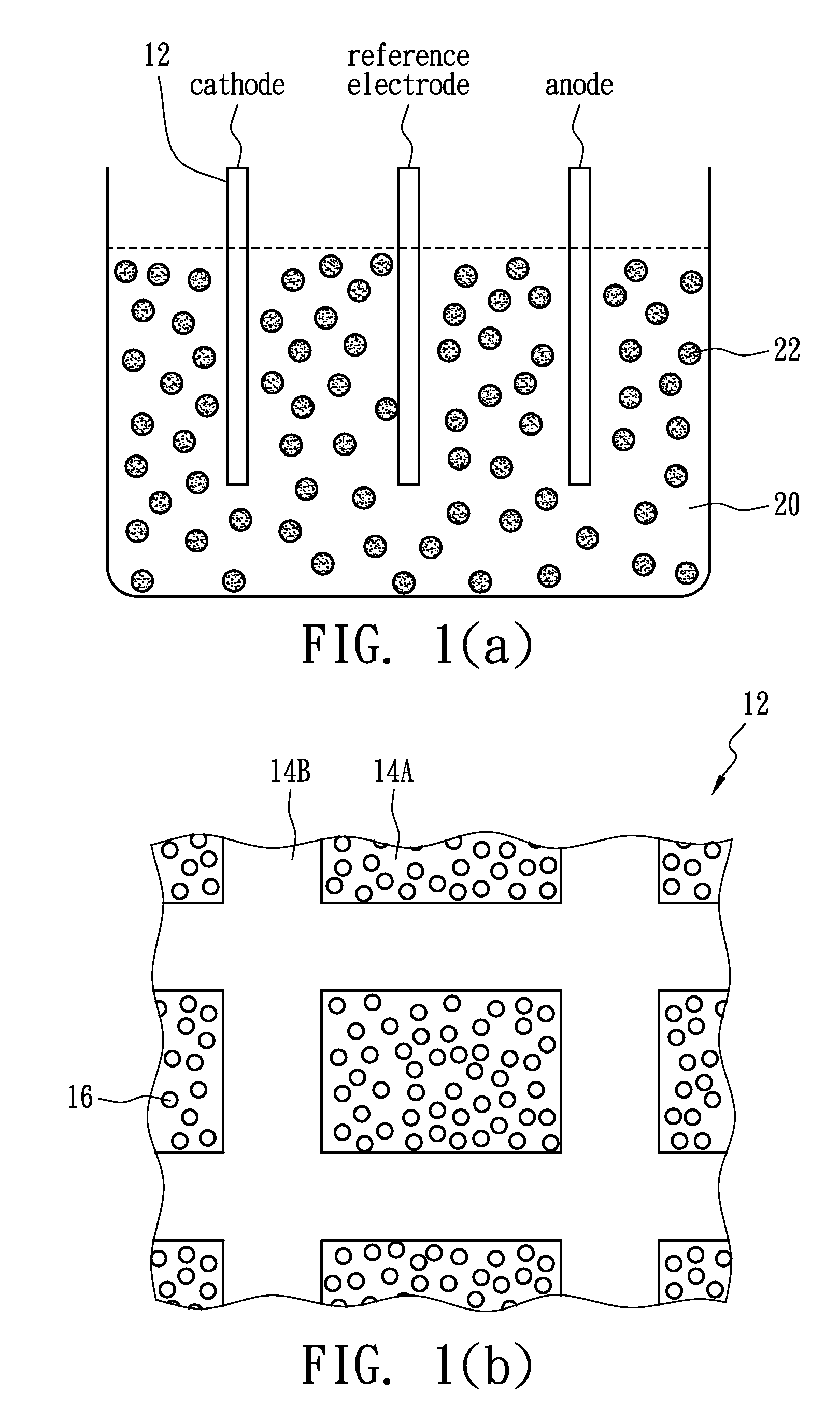

[0024]FIGS. 1(a) and 1(b) illustrate methods for preparing nano metallic particles 16 according to the present invention. A conductive substrate 12 is dipped in an electroplating solution 20 containing metallic ions 22, and an electroplating process (e.g., cyclic voltammery electroplating process) is then performed to form nano metallic particles 16 on the conductive substrate 12 by the reduction reaction of the metallic ions 22. Preferably, the size of the nano metallic particles 16 is between 1 nm and 150 nm. Preferably, the conductive substrate 12 includes indium-tin-oxide (ITO) with the lattice size between 5 nm and 500 nm. The electroplating solution 20 may include nickel nitrate, nickel sulfate or nickel chloride, and the nano s metallic particles 16 may be nickel metallic particle. In addition, the electroplating solution 20 may contain magnetic metallic ions such as iron ions or cobalt ion, and the nano metallic particles 16 may be magnetic metallic particles such as iron pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com