Perforated heat pipes

a technology of perforated pipes and heat pipes, applied in the direction of tubular elements, lighting and heating apparatus, protective garments, etc., can solve the problems of discomfort in dressing, reduced mobility and weight, and long-term benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

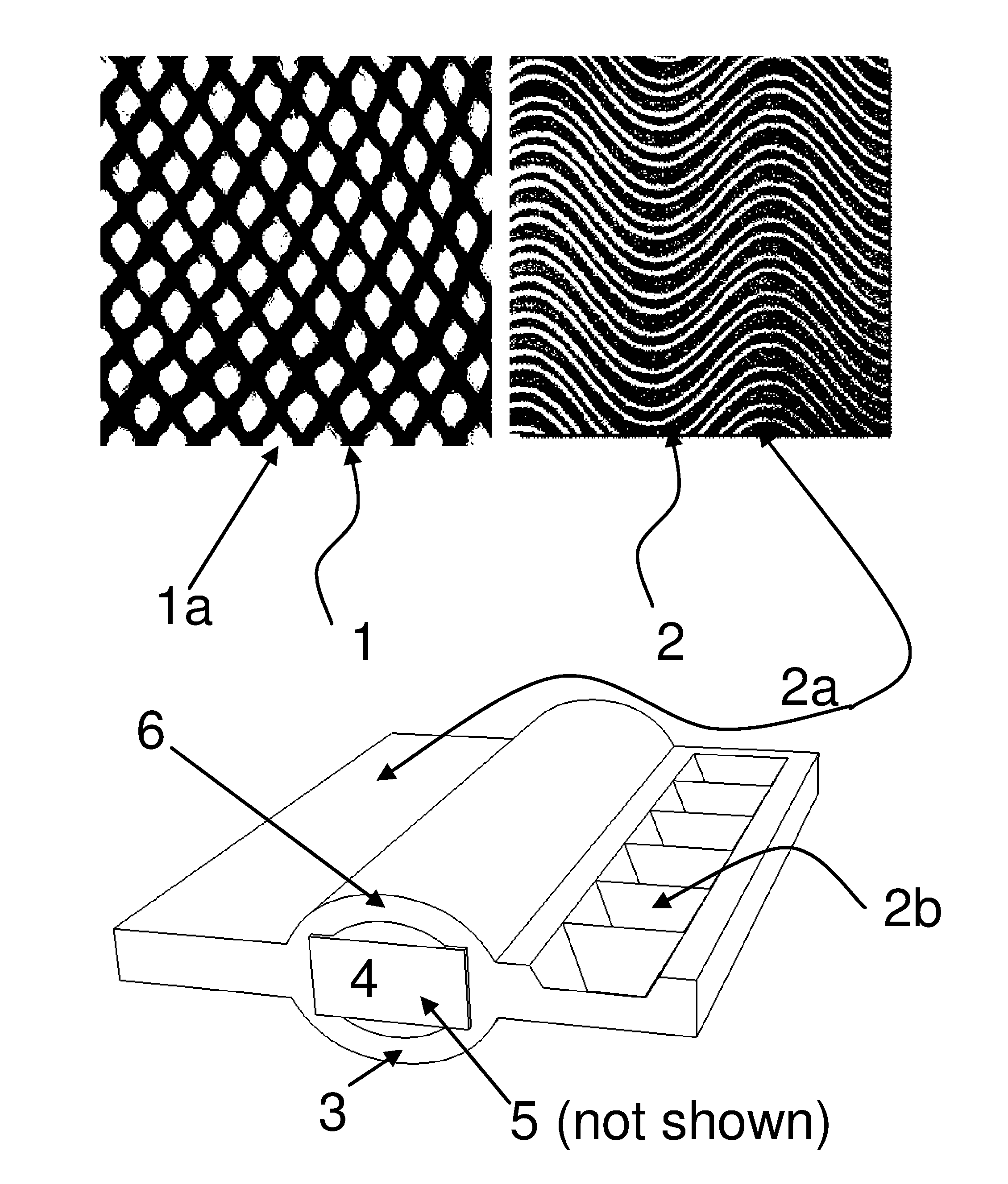

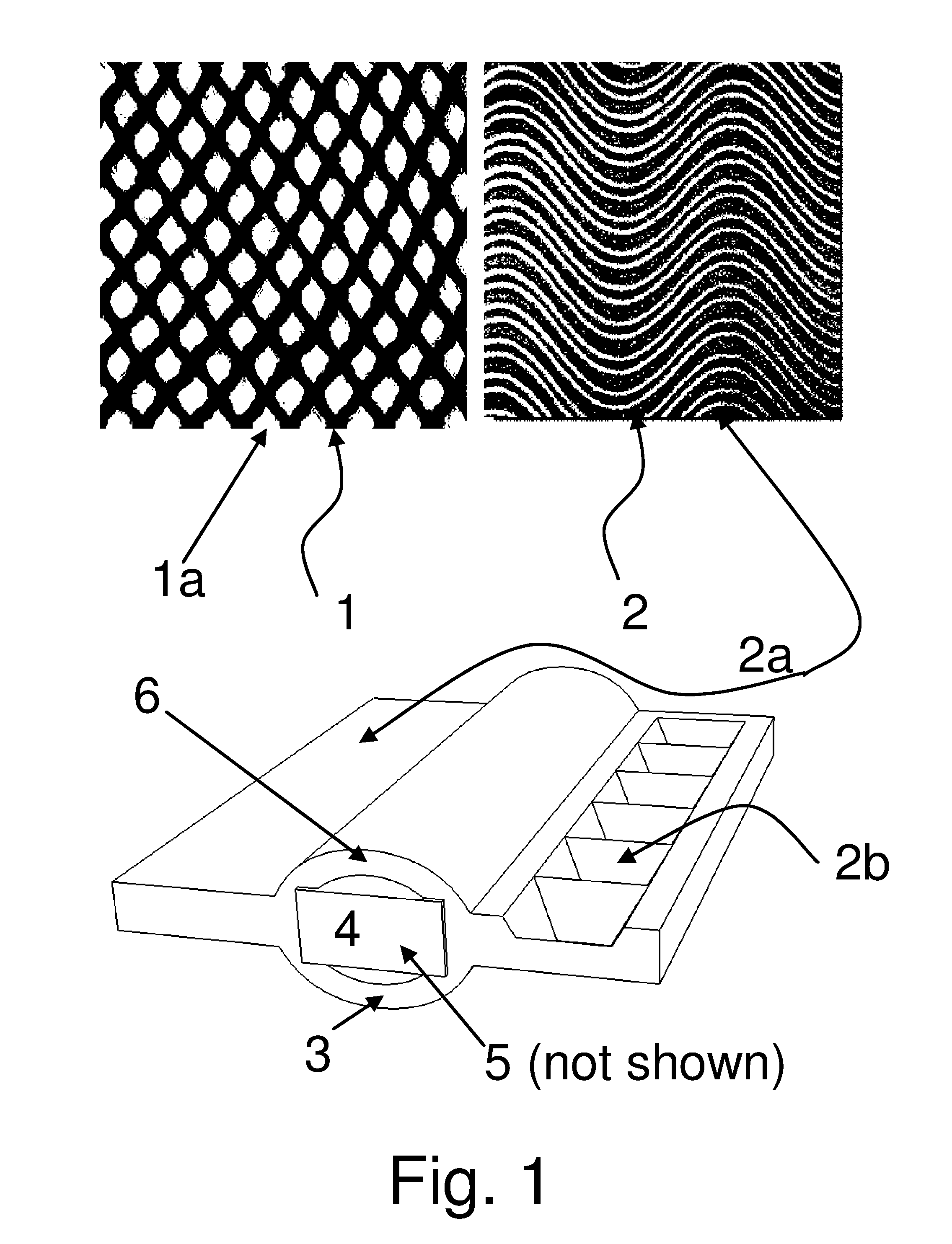

Image

Examples

Embodiment Construction

[0002]The essence of this invention is to provide completely passive lightweight solution that will be able to reduce thermal stress of wearier and have unlimited operating time. Benefit of this invention is effective combination of natural ability of a body to redistribute / manage heat and efficient heat exchange properties of the apparel system combined with its primary functions.

[0003]Each apparel article according to this invention is uniquely designed for a specific use scenario. This makes them comfortable, practical, lightweight, and reliable unlike prior art designs. Heat pipes are employed to increase heat exchange between the body surface and a heat source / recipient (in most scenarios ambient air).

[0004]Heat pipe uses a thin shell impermeable or partially impermeable to gases. Material of choice for the shell is:[0005]laminated single or multilayer metal foil (aluminum or other)[0006]inorganic film (silicate based or other)[0007]polymer or rubber (natural or synthetic with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com