Plasma Nozzle Array for Providing Uniform Scalable Microwave Plasma Generation

a plasma nozzle array and microwave plasma technology, applied in plasma technology, energy-based chemical/physical/physico-chemical processes, disinfection, etc., can solve the problems of one or more plasma species temperatures, high cost of operation, thermal sensitivity and destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 122

[0061]FIG. 4C is a cross-sectional diagram of an alternative embodiment 122 of the microwave cavity and nozzle array depicted in FIG. 4B. As illustrated, a nozzle 128 has similar components as those shown in FIG. 4B. FIG. 4C includes a gas flow tube 134 sealingly connected to a wall 126 to a receive a gas through a gas flow channel 127; a rod-shaped conductor 130 for collecting microwaves from the high-energy regions 69 in a cavity 133; and a vortex guide 132. The gas flow tube 134 may be made of any material that is substantially transparent to microwaves (i.e., microwaves can pass through the gas flow tube 134 with very low loss of energy) and, as a consequence, the gas flowing through the gas flow tube 134 may be pre-heated within the cavity 133 prior to reaching the region of the tapered tip of the rod-shaped conductor 130.

embodiment 140

[0062]FIG. 4D shows a cross-sectional view of another alternative embodiment 140 of the microwave cavity and nozzle array depicted in FIG. 4A. As illustrated, nozzles 144 have components similar to their counterparts in FIG. 4B: a gas flow tube 148 sealingly connected to a wall 143 of a microwave cavity 142 to receive a gas; a rod-shaped conductor 152 for collecting microwaves from the high-energy regions 69; and a vortex guide 146. The microwave cavity 142 may form a gas flow channel connected to the gas tank 34. The rod-shaped conductor 152 may be similar to the conductor 114 illustrated in FIG. 4B where the portion 116 of the rod-shaped conductor 114 is inserted into the cavity 113 to receive microwaves. Then, the received microwaves travel along the surface thereof and are focused on the tapered tip.

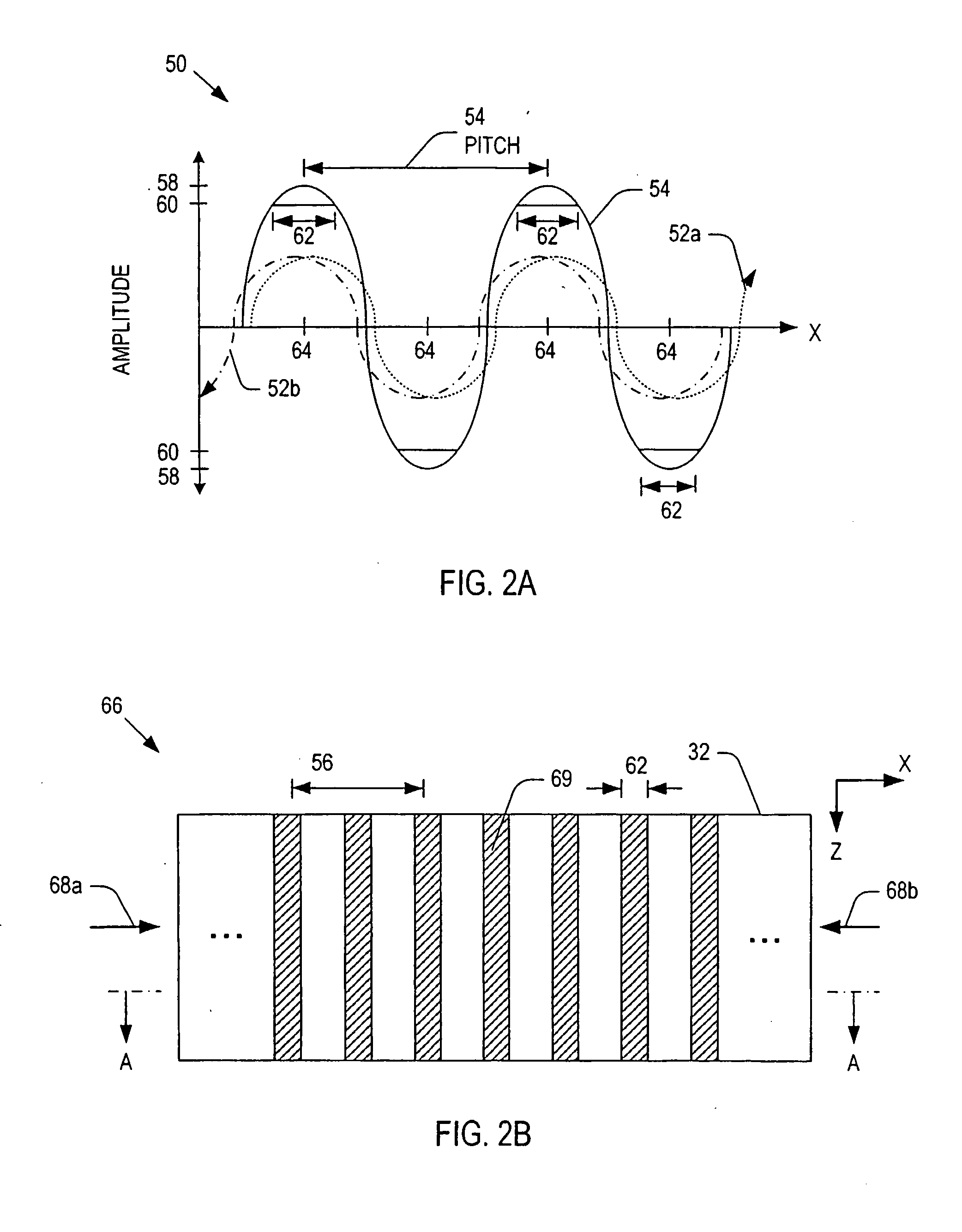

[0063] A mentioned previously, the width 62 (FIG. 2) of the high-energy regions 69 may be optimized by controlling the non-rotating phase shifters 24a and 24b. In general, a smaller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com