Multi-layered film window system

a film window system and multi-layer technology, applied in the field of energy-efficient windows, can solve the problems of preventing the application of curtain-wall covers, difficult to construct such covers to be weather-tight, reliable, movable, etc., and achieve the effect of reducing solar gain and promoting solar heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

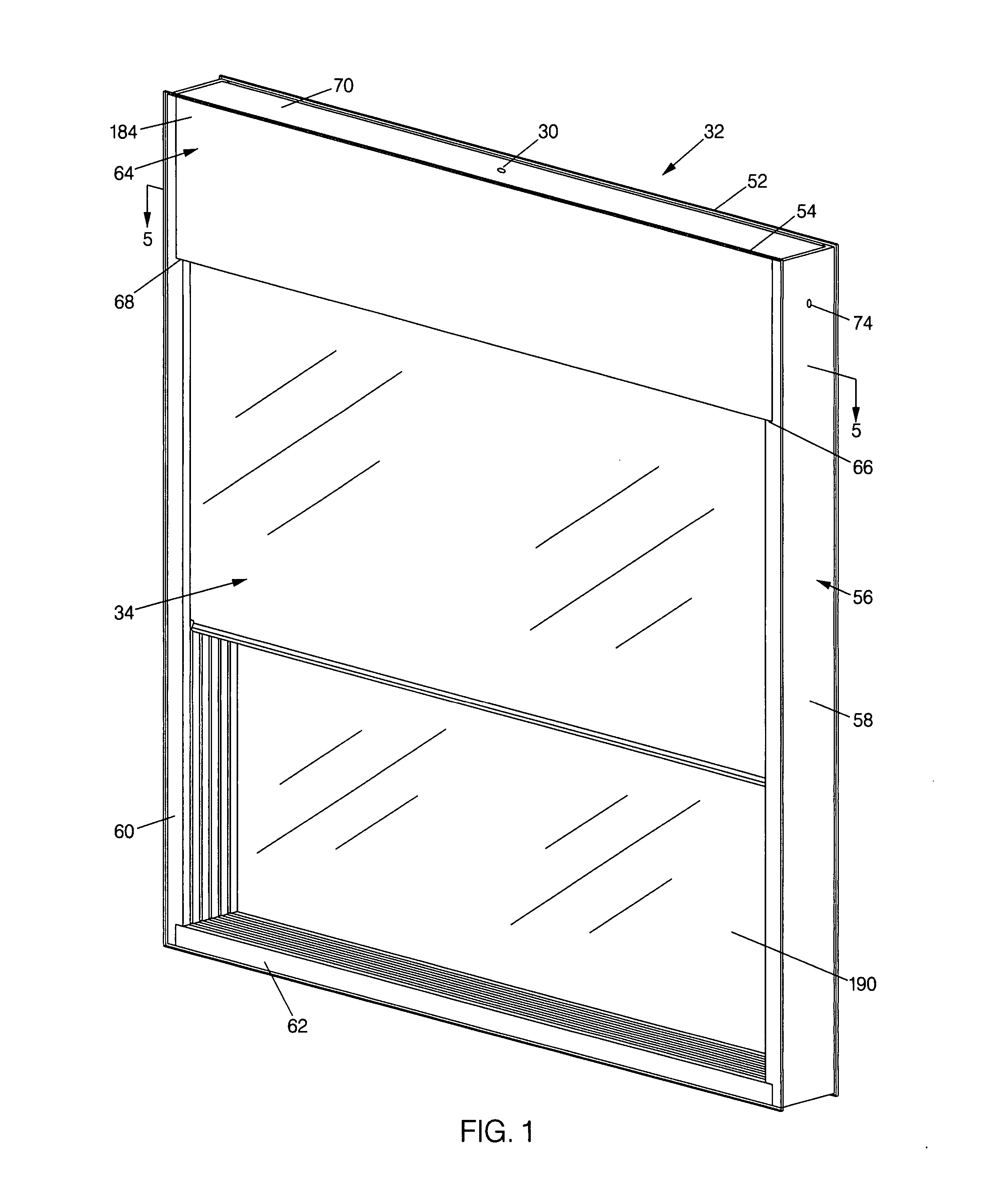

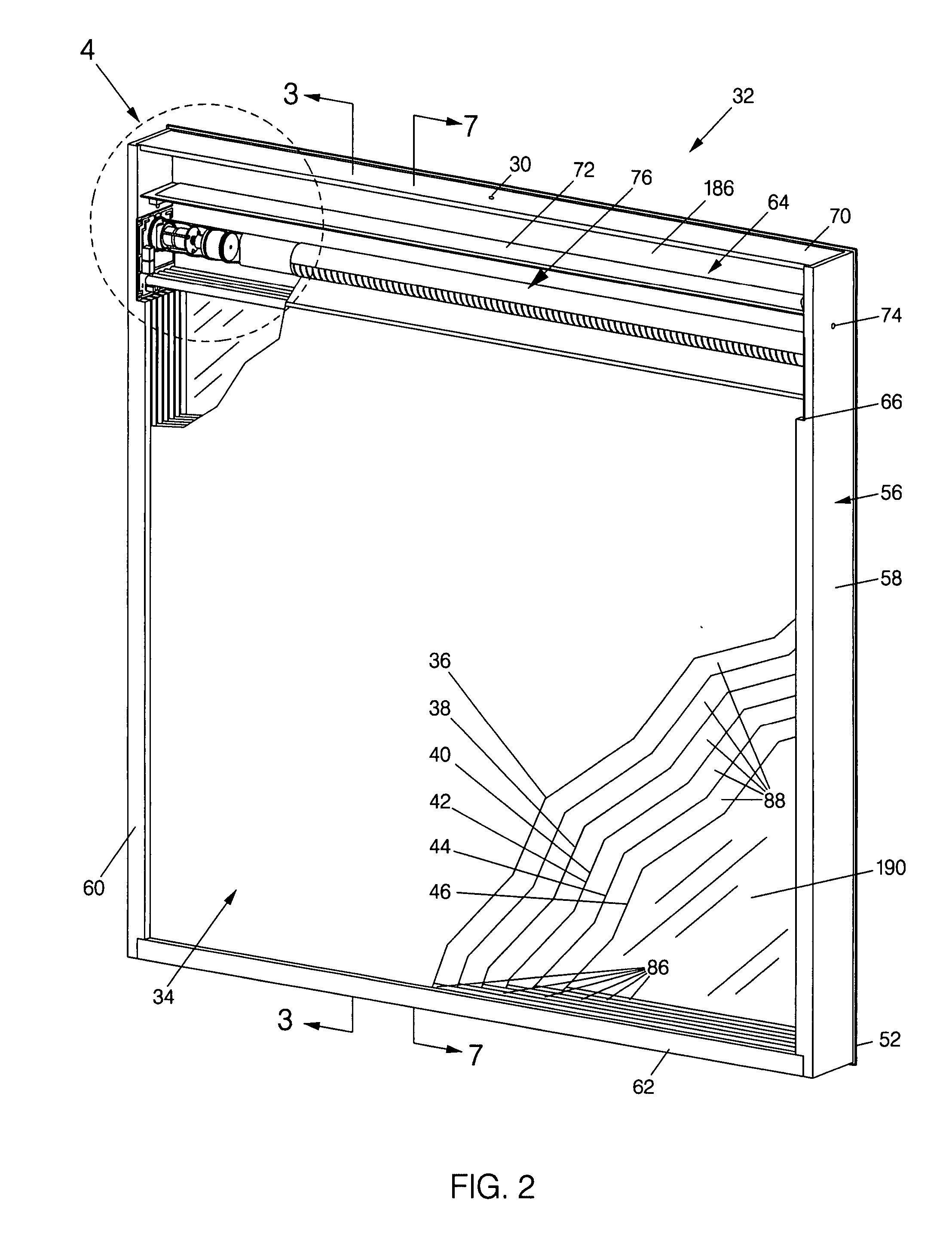

[0059] As generally noted above, the invention seeks to provide a sealed, glazed window assembly 32 having two layers of glass 52 and 54 or other suitably transparent material separated by several intermediate film layers 36-46. The assembly 32 is designed to demonstrate an insulation R-value on the order of a frame wall (e.g. R18 to R20). In contrast, a typical frame wall R-value of 19 is achieved with fiberglass bats fitted in a 6″ solid, opaque framed wall.

[0060] The significance of the capabilities of the assembly 32 can be appreciated upon consideration of the applicable physics relating to multi-layered glazed assemblies and available multi-layered windows. The physics of the assembly 32 derives from basic considerations that glass is transparent in the visible spectrum and a layer of glazing transmits approximately 95% of incident sunlight. A single layer of glass, which has a through-glass resistance of about 0.02 hrft2F / BTU has a measured R-value of about 1.0 hrft2F / BTU. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com