Combustion apparatus

a combustion apparatus and combustion chamber technology, applied in lighting and heating apparatus, domestic stoves or ranges, heating types, etc., can solve the problems of inability to complete combustion, inability to fully burn wood, and inability to emit combustion gases and particulates, etc., to achieve clean, smokeless burning, and high heat energy. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

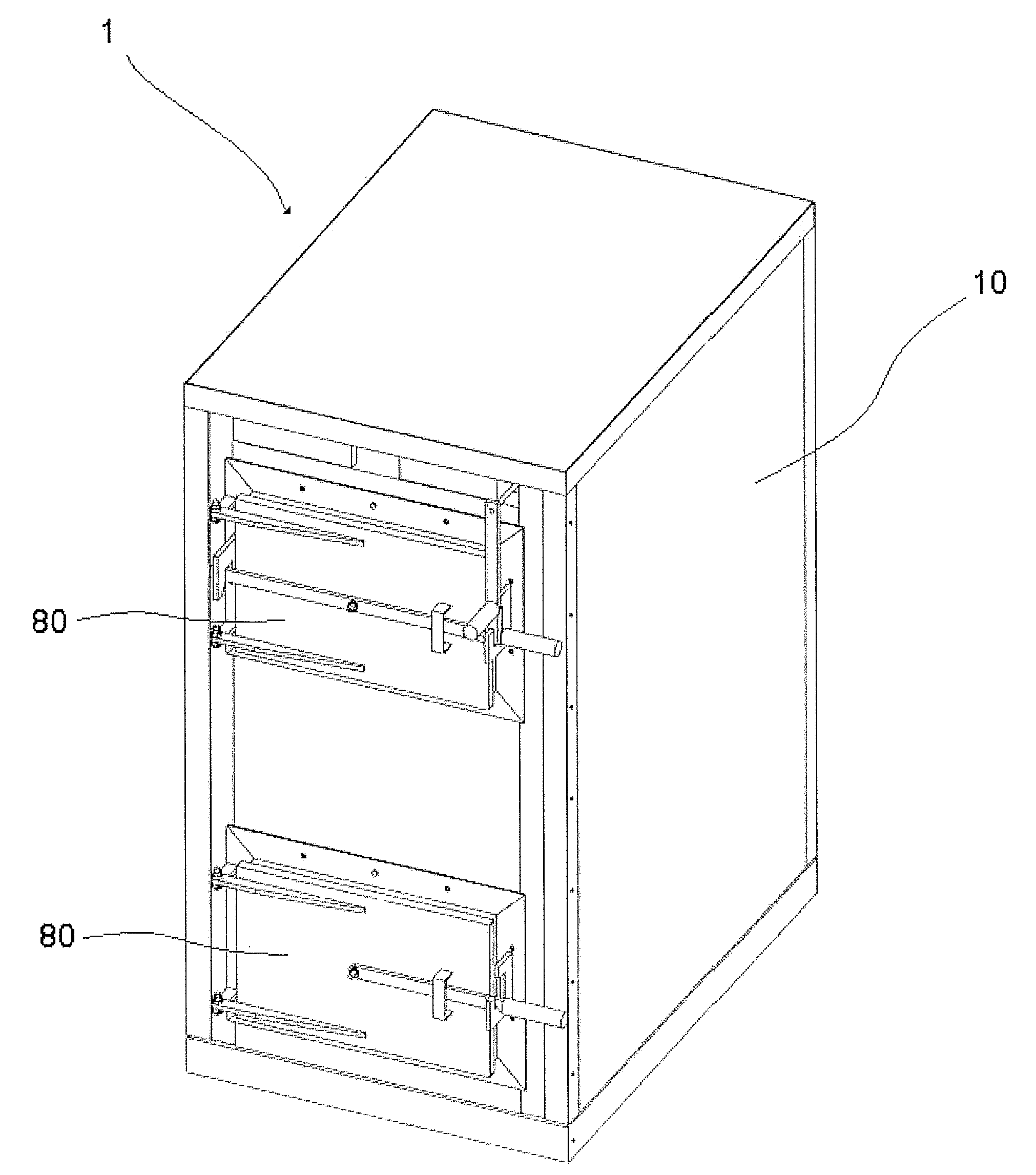

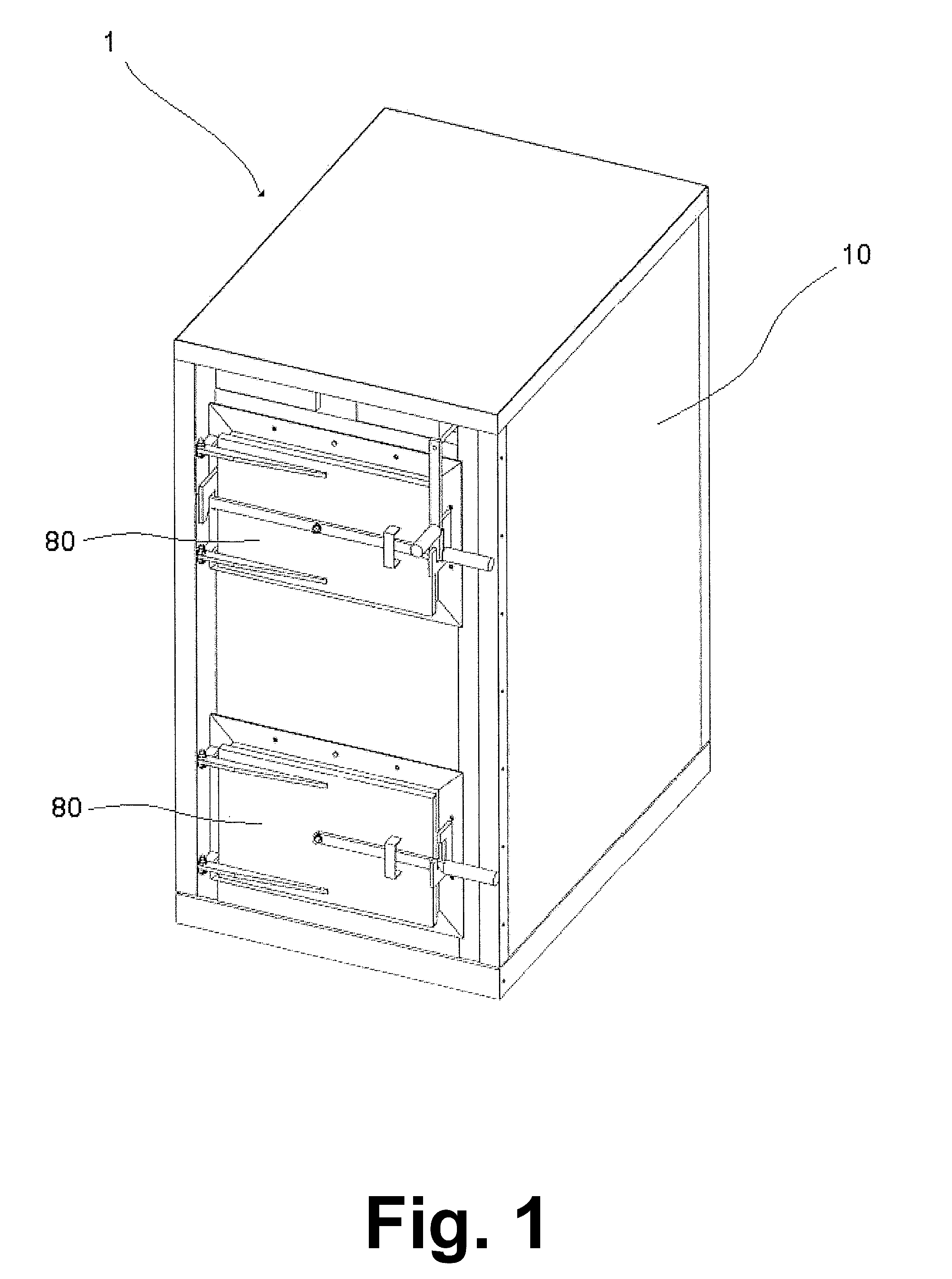

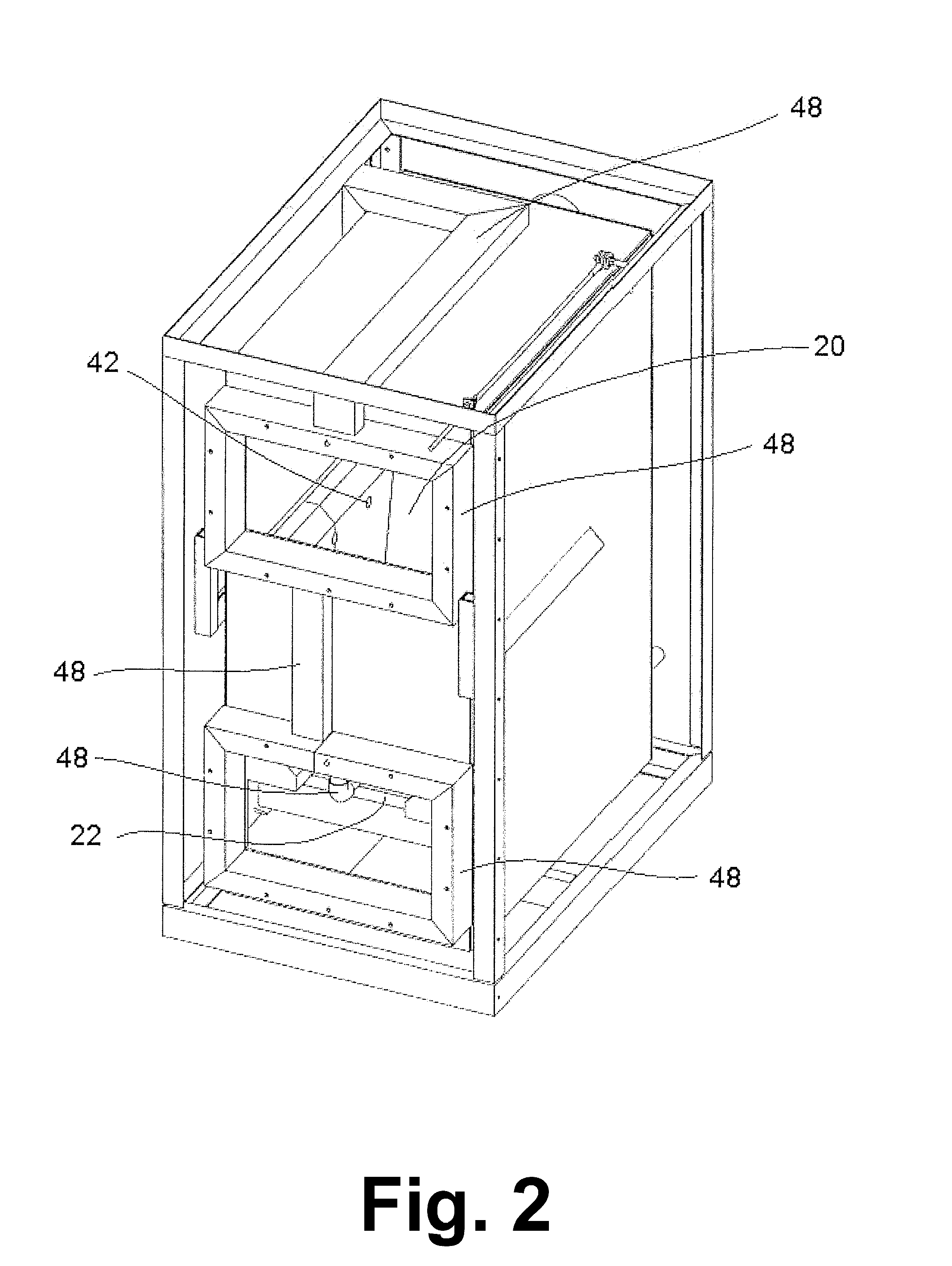

[0035]The combustion apparatus 1 of the present invention is comprised of an insulated housing 10, a primary combustion chamber 20, a secondary combustion chamber 22, a divider 30 disposed between and separating the primary and secondary combustion chambers 20,22, an oxygen introduction mechanism 40, a pressurizing mechanism 50, and an exhaust structure 60.

[0036]The housing 10 of the present invention is constructed of a heavy-duty metallic material, such as steel or cast iron, though other materials may also be used. It comprises insulation within its interior sufficient to allow for safe contact of the outer surface during operation of the combustion apparatus 1. The housing 10 defines an internal space in which the other elements are located, though portions of the pressurizing mechanism 50 and the exhaust structure 60 extend outside the housing 10. See FIGS. 1, 5, 8, 9, and 10. One or more access doors 80 may be provided to allow access into the interior of the housing 10. See F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com