Double-wall plastic produce container having ventilation holes therein, and mold for the manufacture thereof

a technology of plastic produce containers and ventilation holes, which is applied in the direction of containers, domestic articles, packaged goods, etc., can solve the problems of difficult to eliminate porosity from this type of hole structure, and type of hole structure has been found unsuitable for application, so as to prevent the occurrence of porosity, good contact, and uniform melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]While this invention is susceptible of embodiment in many different forms, there are shown in the drawings and will be described in details herein one specific embodiment of a double-wall ventilated container, with three different preferred ventilation hole structures, with the understanding that the present disclosure is to be considered as an example of the principles of the invention and is not intended to limit the invention to the embodiment and preferred hole structures illustrated and described.

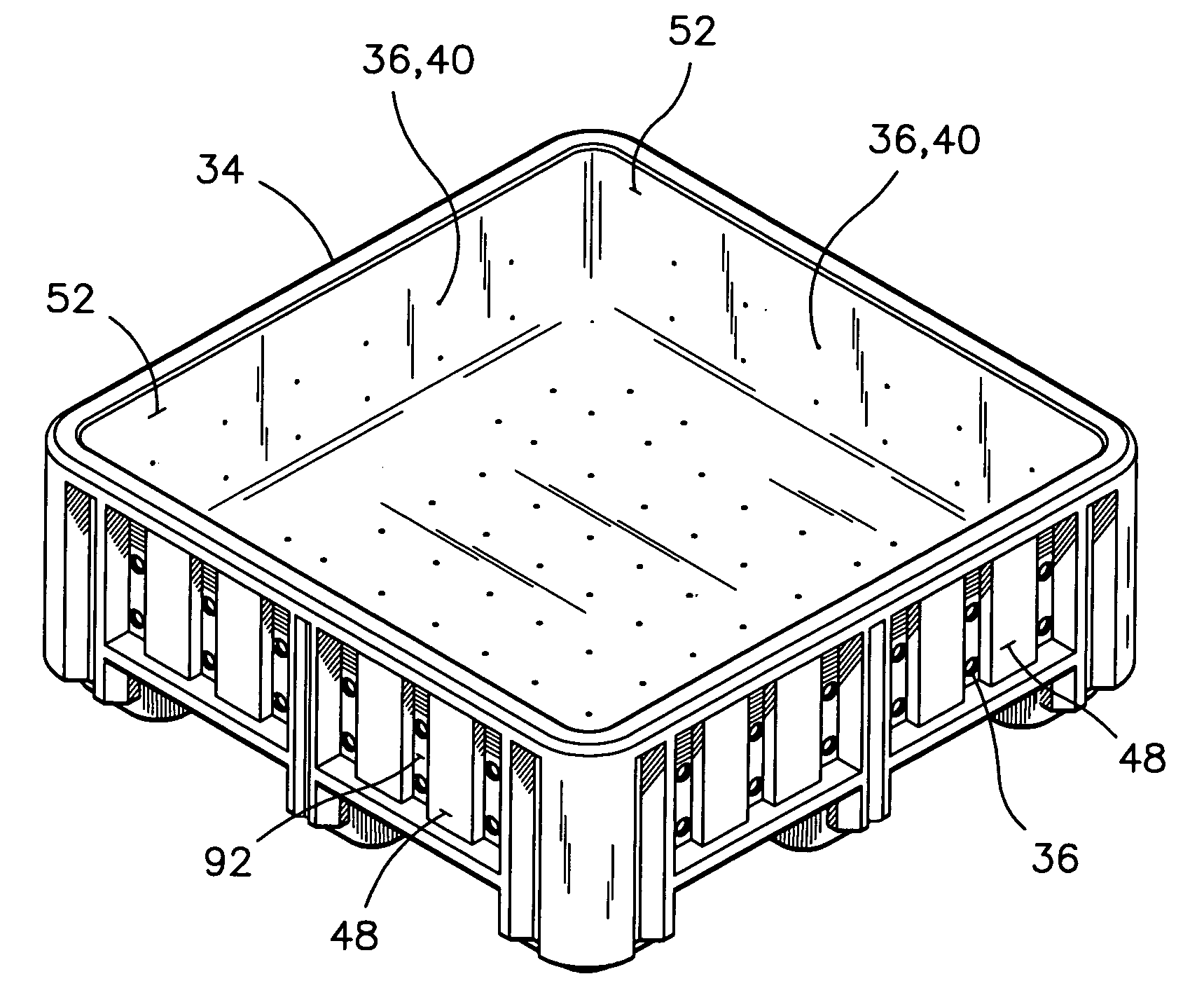

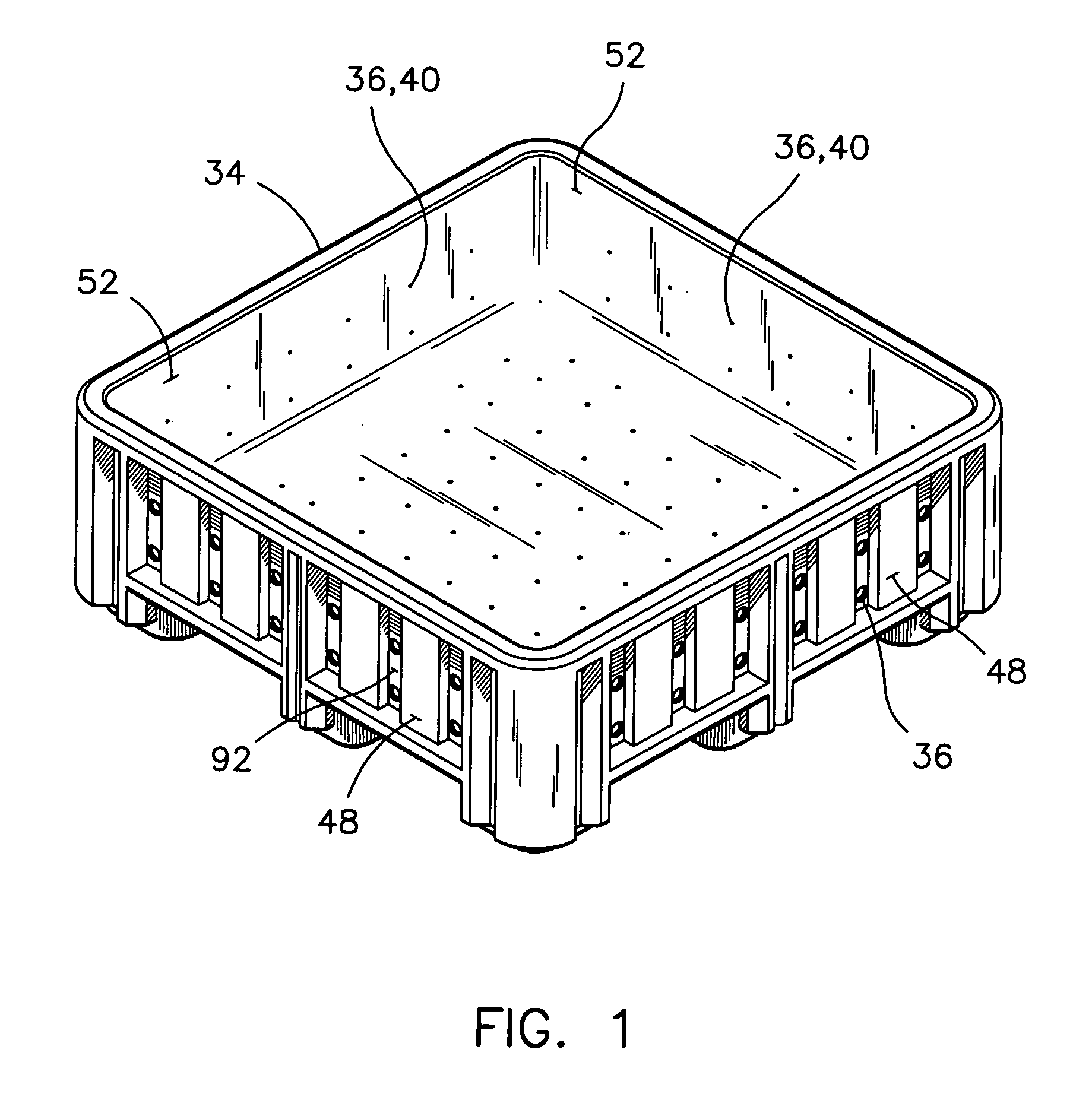

[0027]For reference purposes, FIG. 1 illustrates a stackable, double-wall plastic produce container 34 with ventilation holes 36 according to one of the preferred hole structures described and illustrated herein.

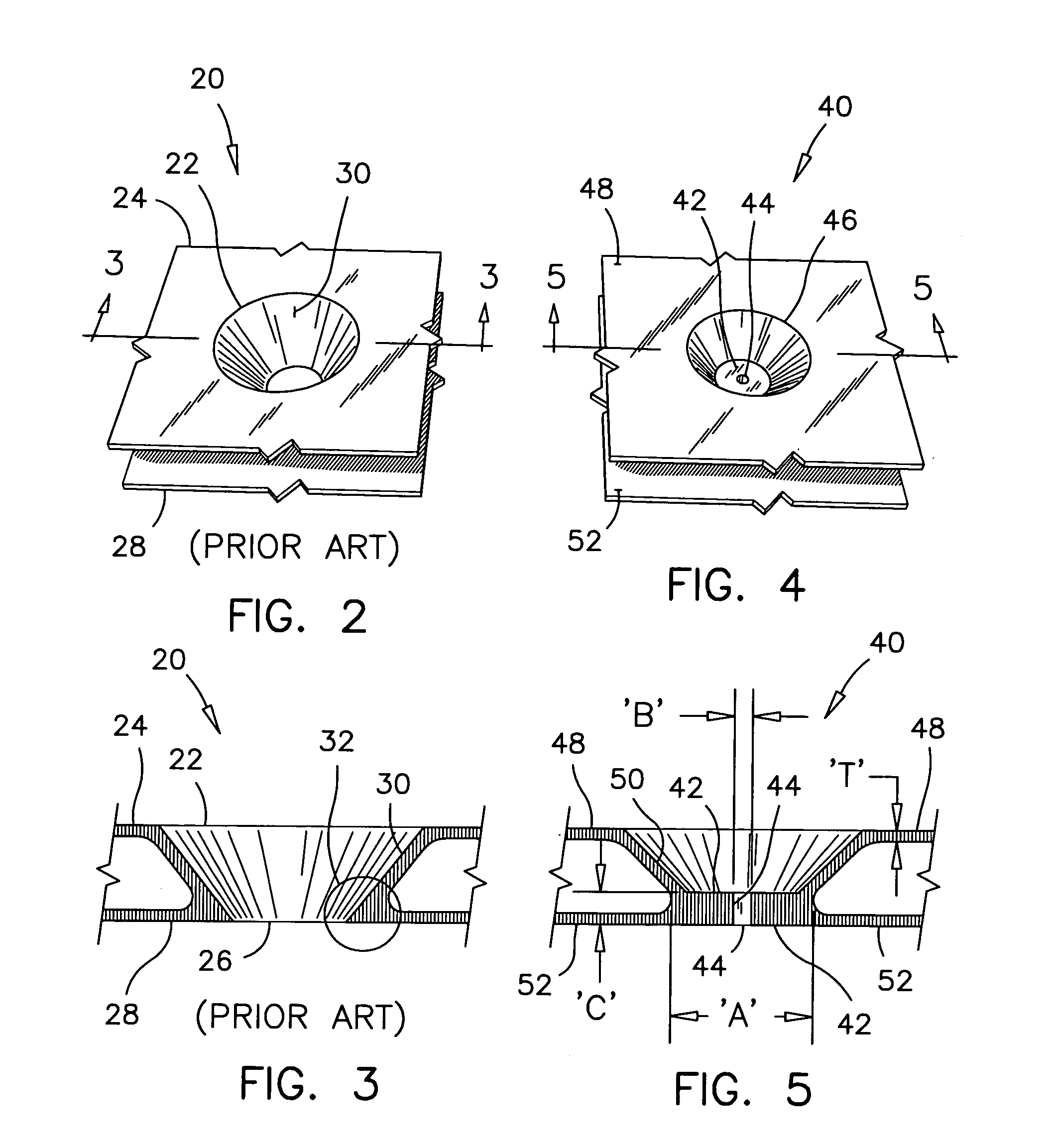

[0028]Referring now to FIGS. 4 and 5, the first preferred hole structure 40 is illustrated therein. The first preferred hole structure 40 is distinguishable from the hole structure 20 of the prior art, as shown in FIGS. 2 and 3, for having a flat disc-like solid flange 42...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angles | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com