Drum washing machine with detergent supply device

a technology of detergent supply device and drum washing machine, which is applied in the field of drum washing machine, can solve the problems of increasing increasing the number of components, and difficulty in manufacturing the washing machine, and achieves the effects of reducing the production cost of the washing machine, facilitating manufacturing, and simplifying the structure of the detergent supply devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

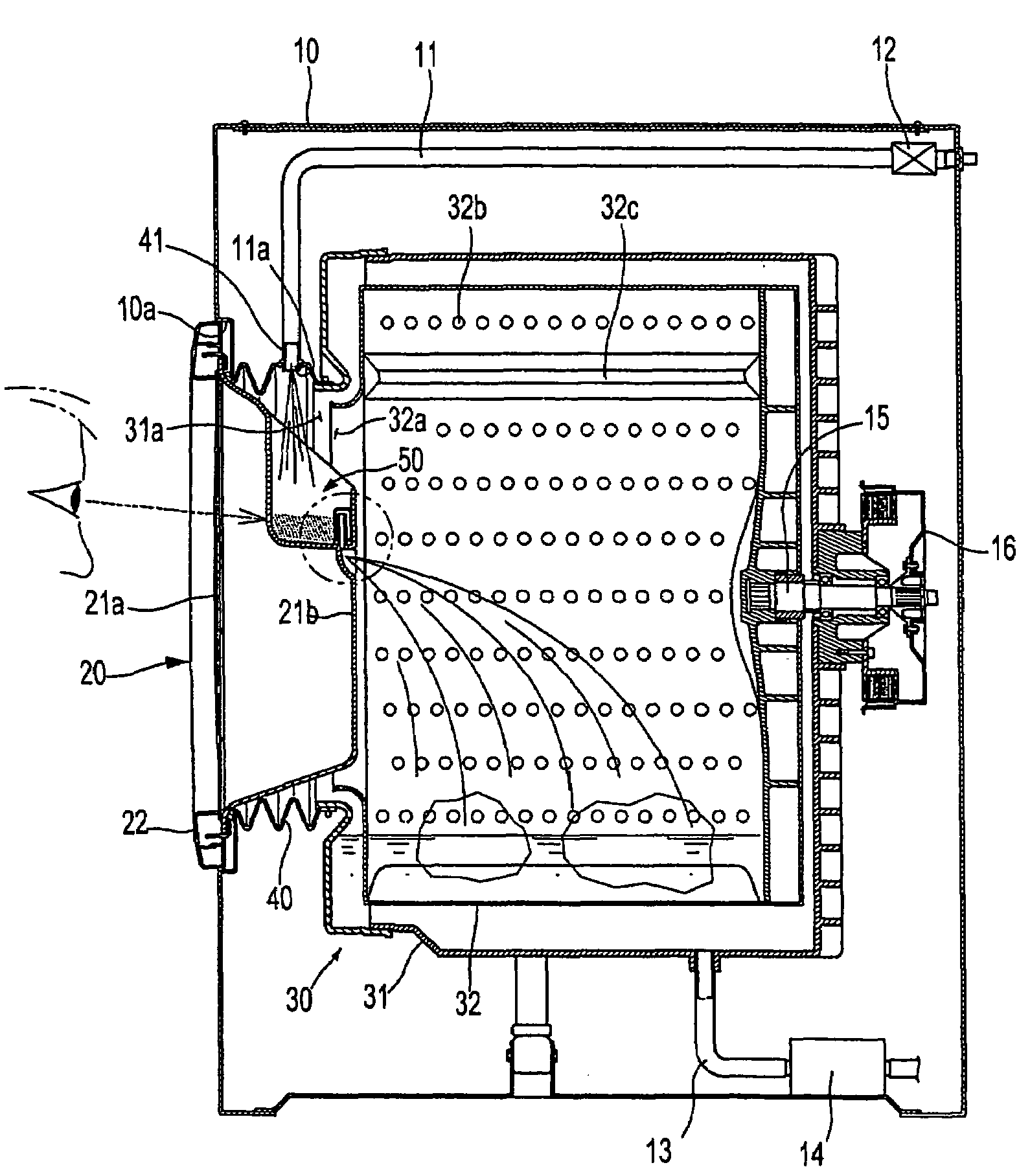

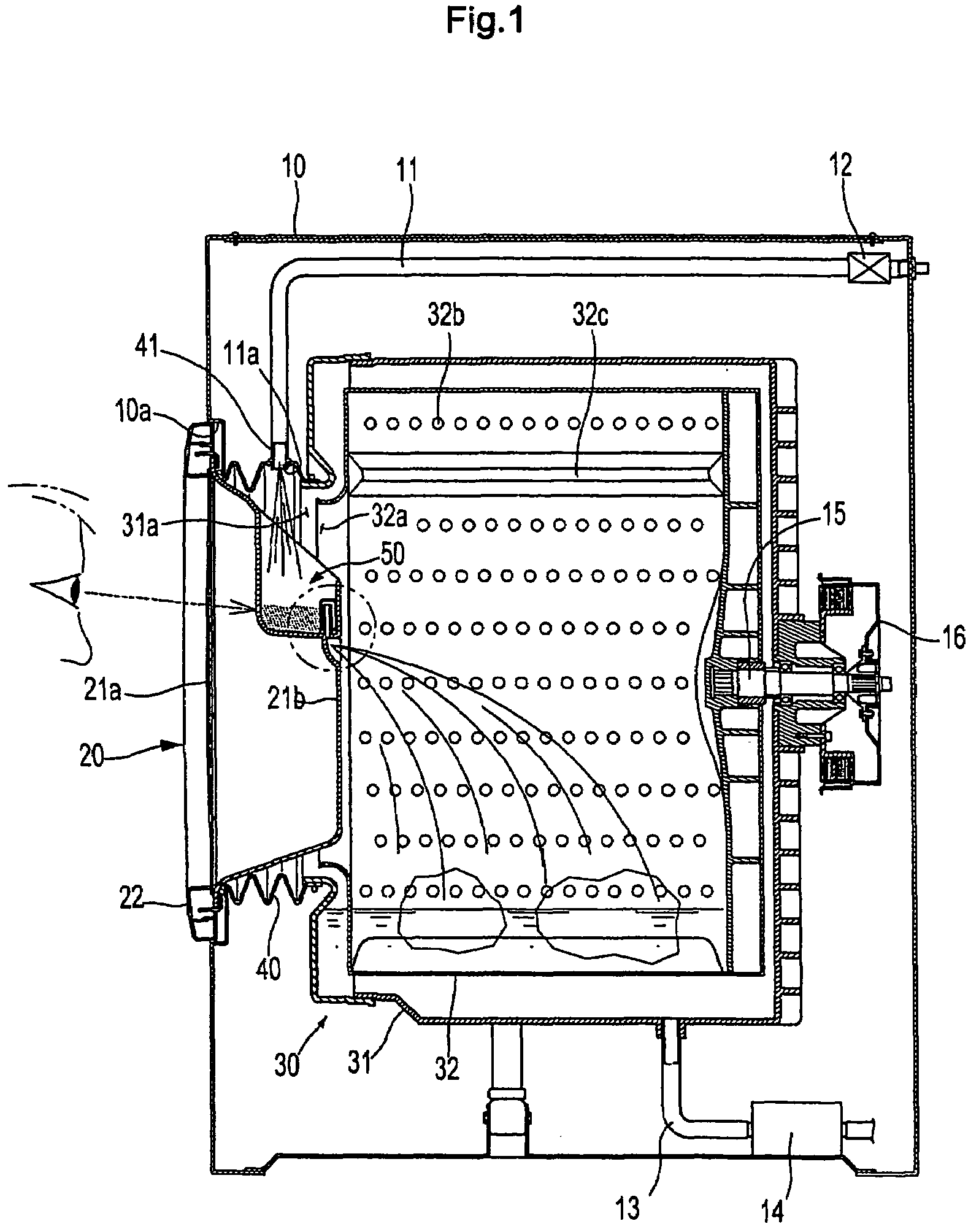

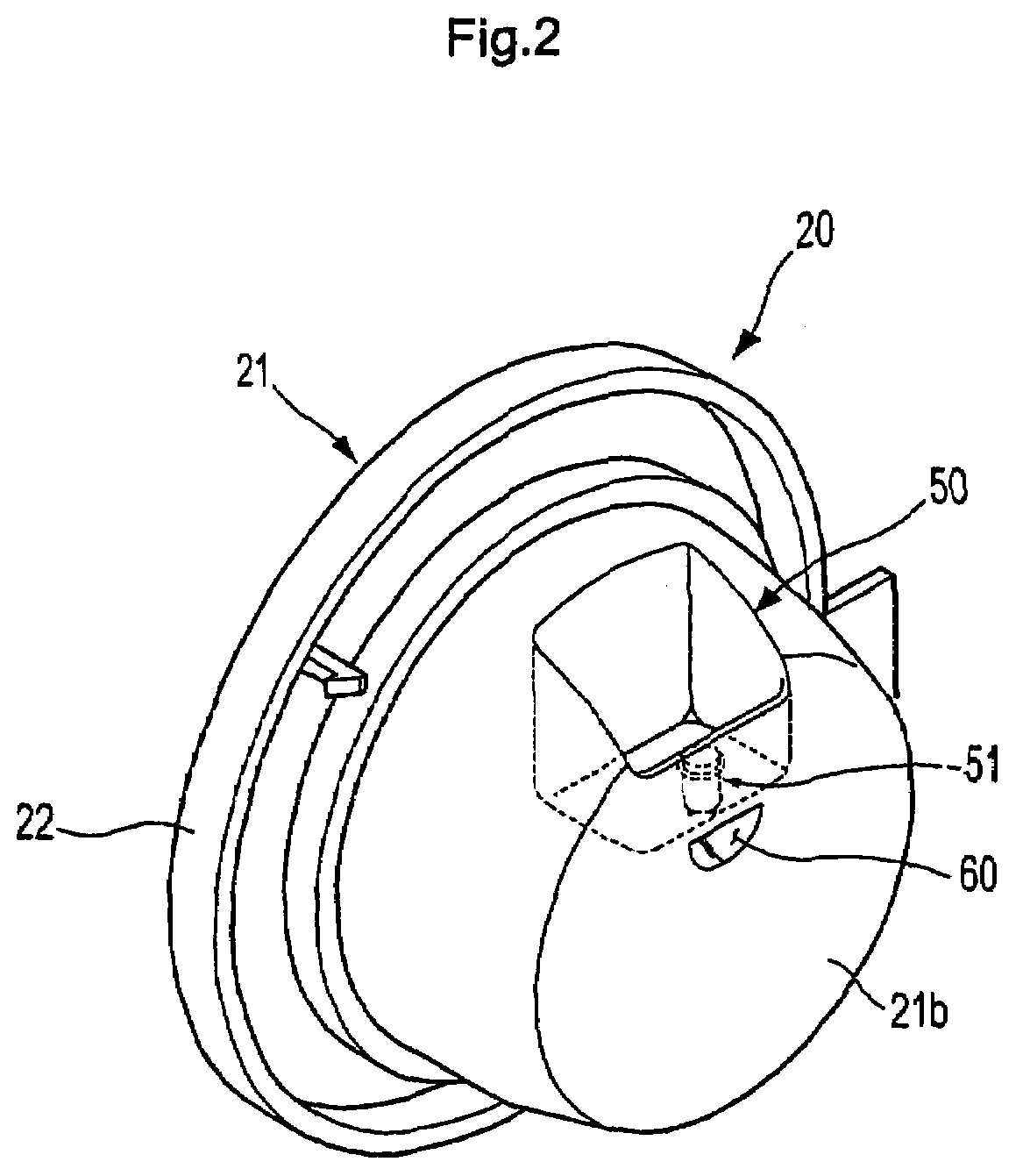

[0031]As shown in FIG. 1, a drum washing machine of the present invention includes a main body 10 forming an external appearance of the drum washing machine, a door 20 connected to a front surface of the main body 10 such that the door 20 can be opened and closed so that laundry can be inserted into and removed from the main body 10 of the washing machine, and an operation unit (not shown) provided on the main body 10 above the door 20 to operate the washing machine.

[0032]A cylindrical washing tub 30 provided with an opening formed through the front surface thereof is installed in the main body 10 of the washing machine. The opening of the washing tub 30 faces the door 20. The washing tub 30 has a double structure including a body 31 of the tub 30 and a drum 32. The tub body 31 stores water required during a washing operation, and the drum 32 is rotatably installed in the tub body 31 to perform the washing operation.

[0033]A water supply device supplying water to the tub body 31 is i...

second embodiment

[0050]FIG. 5 illustrates a detergent supply device 70 of a washing machine in accordance with the present invention. The detergent supply device 70 includes a plurality of chambers 71 and 72, which are divided from each other so that various kinds of detergents can be respectively put into the plurality of chambers 71 and 72.

[0051]The plurality of chambers 71 and 72 include a detergent chamber 71 and a softener chamber 72, which are divided by a partition 73. The detergent chamber 71 stores a detergent used in a washing operation, and a softener chamber 72 stores a fabric softener used in a rinsing operation.

[0052]Generally, the detergent used in the washing operation has a powdery state, and the fabric softener used in the rinsing operation has a liquid state. Accordingly, a discharge hole 71a discharging the detergent dissolved in the water is formed through the rear surface of the detergent chamber 71, and a siphon unit 74 to discharge the fabric softener by a siphon is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com