Apparatus for Processing Highly Corrosive Agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

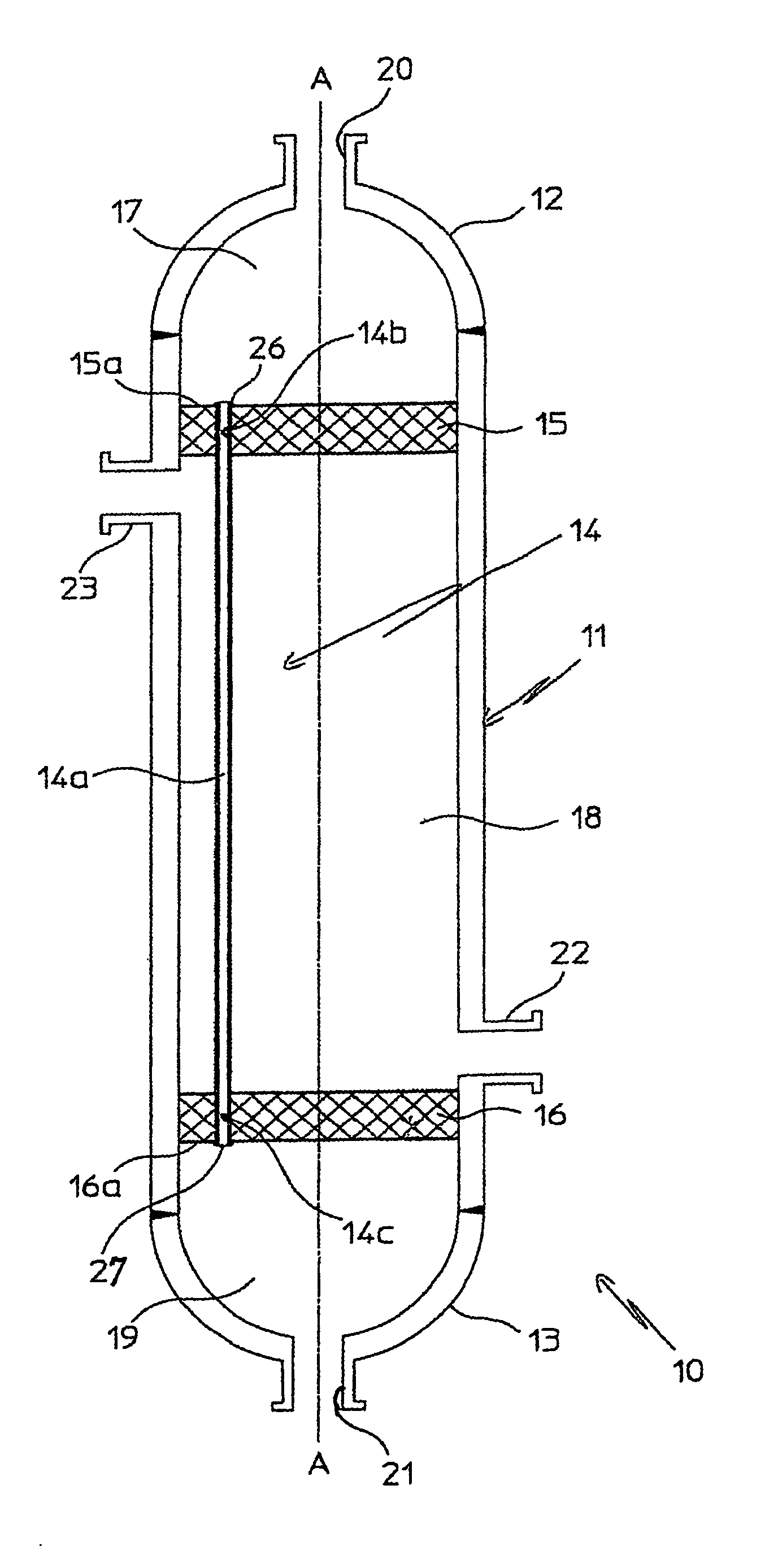

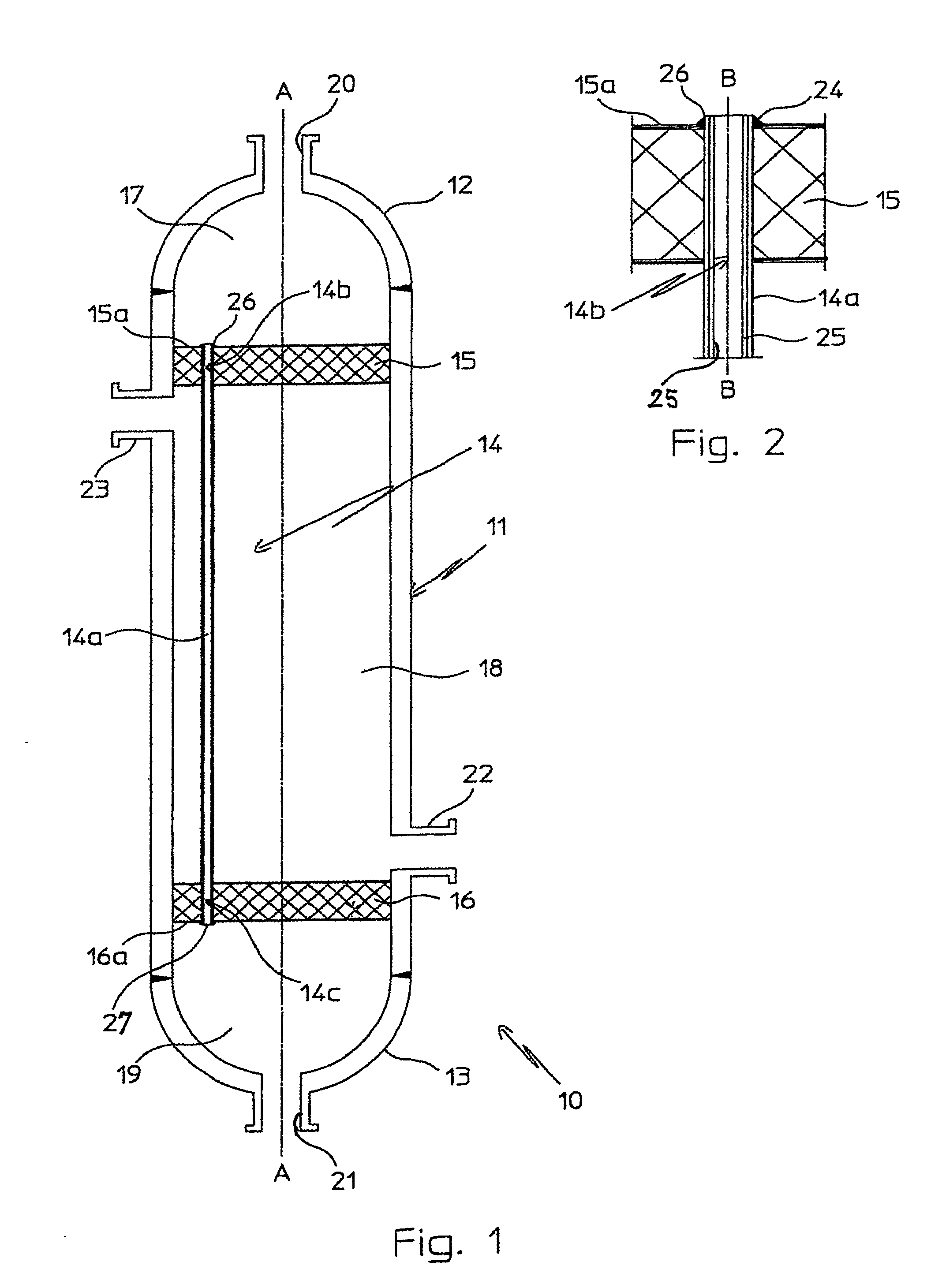

[0029] With reference to the aforementioned figures, the heat exchange apparatus according to the invention shall be described, purely for indicating and not limiting purposes, with specific reference to a descending film tube bundle heat exchanger 10, with vertical tubes, that has advantageous and specific use as a stripper of a urea production plant, but it is clear that it can be used as a condenser, evaporator, boiler, reactor or similar apparatuses based upon the heat exchange between two fluids.

[0030] In particular, the heat exchanger 10 according to the invention has advantageous and specific use as a stripper or condenser in a high pressure synthesis section of an urea plant, and more precisely of a urea plant of so-called CO2 or ammonia stripping, not represented because it is conventional. Such a section generally comprises at least one synthesis reactor, a stripper for the decomposition of the ammonium carbamate and of the-free ammonia present in the reaction mixture com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com