Swinging Apparatus

a technology of swinging apparatus and swinging rod, which is applied in the direction of movable seats, transportation items, gearing, etc., can solve the problems of degrading the aesthetic aspect of the apparatus and increasing the size of the apparatus, and achieves the effects of simple structure, reduced apparatus size and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0039] An embodiment of the present invention will be described with reference to FIGS. 1 to 16.

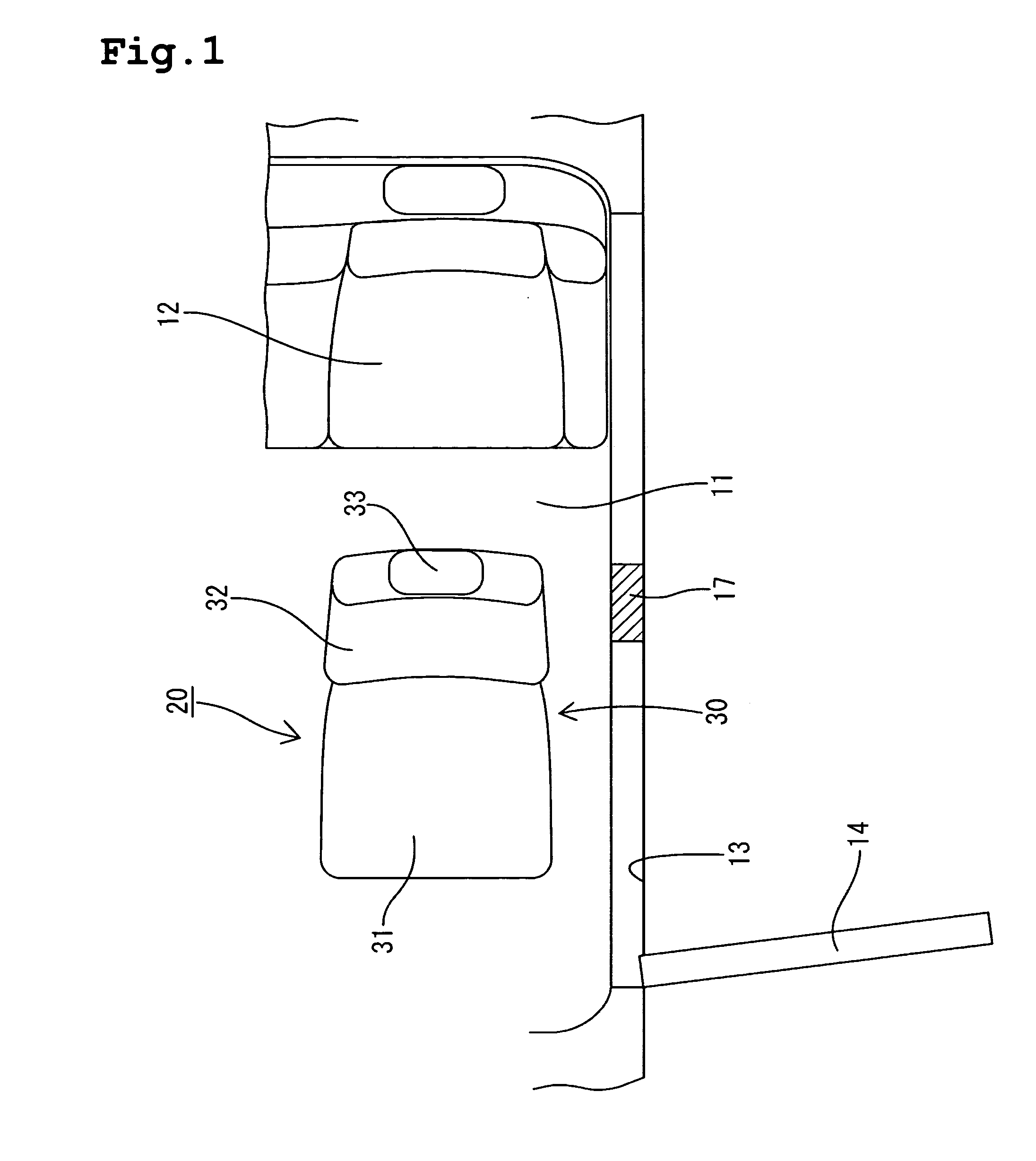

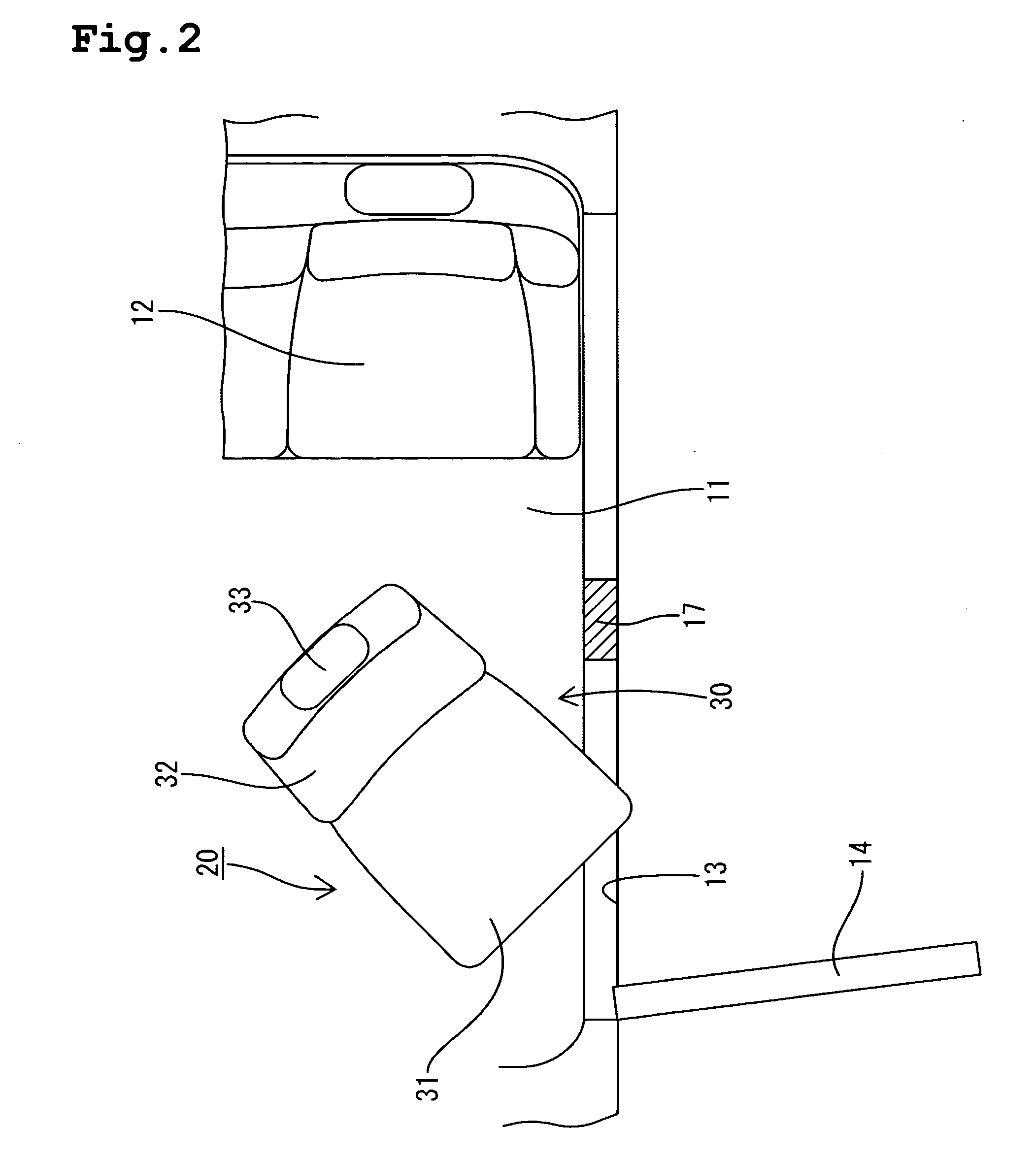

[0040]FIG. 1 shows half of a passenger seat in a car applied to the present embodiment. In a compartment, a passenger seat 20 and a rear seat 12 are arranged on a floor panel 11. A door opening 13 is provided on a side of the passenger seat 20. A door 14 is attached to the door opening 13 so that it can be opened and closed. A center pillar 17 is formed behind the door opening 13.

[0041] The passenger seat 20 is composed of a seat portion 30 consisting of a seat cushion 31, a seat back 32, and a headrest 33, and a rotatively moving and swinging apparatus M. The apparatus M causes the seat portion 30 to perform an internal slide operation for adjusting the seat position in the compartment and an external projecting operation and retracting operation for allowing a passenger to get in or out smoothly. The projecting and retracting operation causes the seat portion 30 to perform a combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com