Controlled time-release algae resistant roofing system

a technology of algae-resistant roofing and controlled time-release, which is applied in the direction of cellulosic plastic layered products, roads, traffic signals, etc., can solve the problems of severe discoloration of the entire roof, accelerate premature roofing failure, and buildup of hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Encapsulated AR Granules

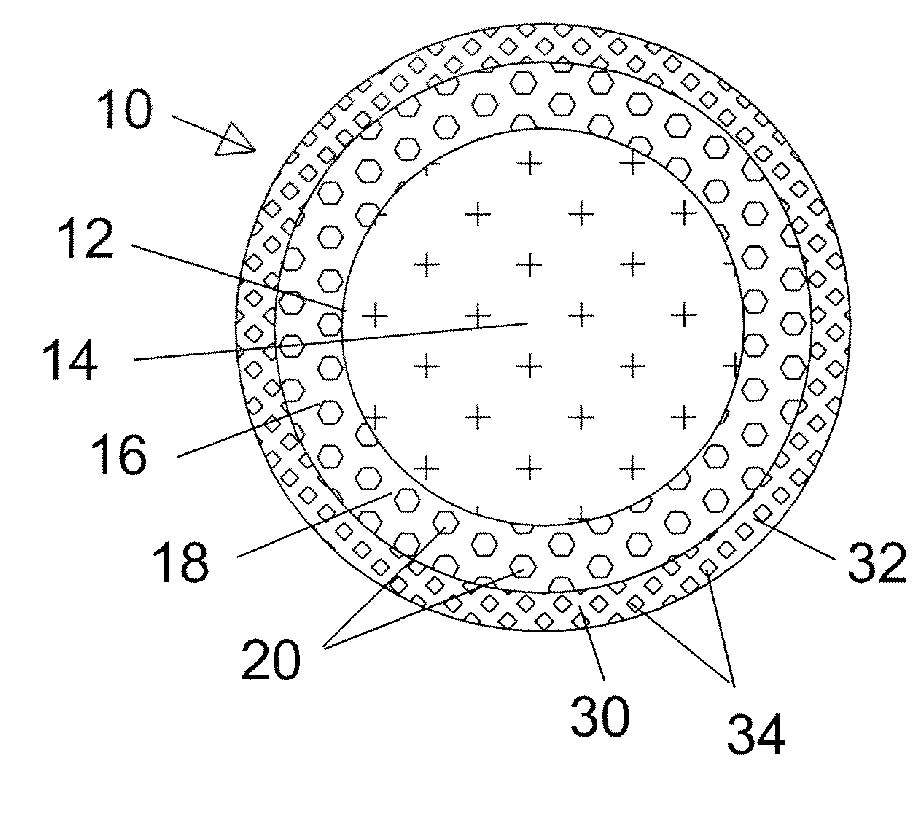

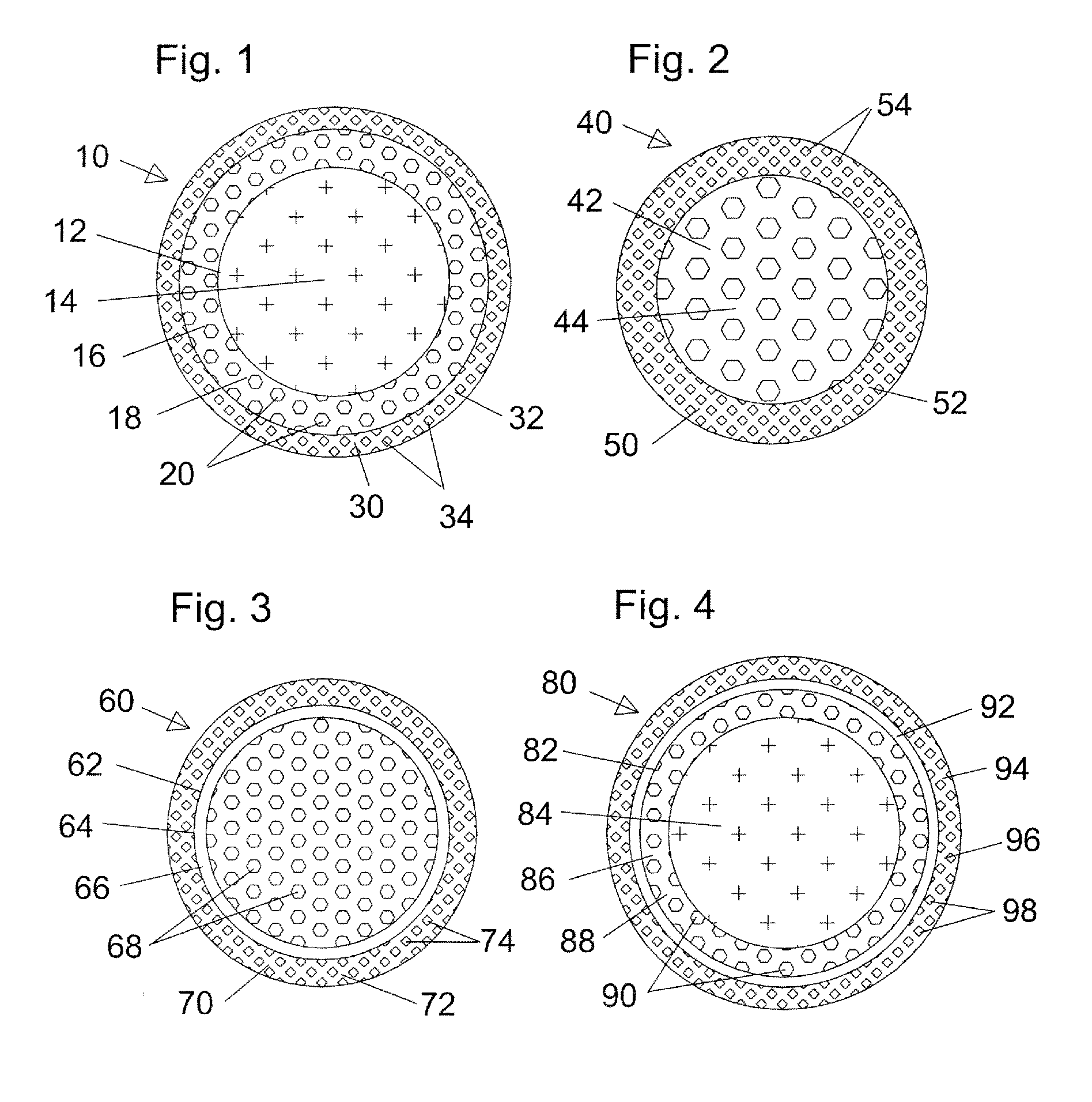

[0115]1,000 g of conventional cuprous oxide-loaded algae resistant (AR) roofing granules (Product Code GH 71 AR) manufactured at CertainTeed's Gads Hill roofing granule plant located at Piedmont, Mo. were used as the base particles. In this case, cuprous oxide acted as the first algaecidal material. These granules were in turn encapsulated with an outer coating. Composition of this outer coating consisted of 125 g of sodium silicate (40% solids, with Na2O:SiO2 ratio of 1:3.2; Occidental Chemical Corporation, Dallas, Tex.), 100 g of clay slurry (70% solids, Unimin Corporation, New Canaan, Conn.), 20 g of titanium oxide (TiPure Product Number R-101, DuPont, Wilmington, Del.) and 120 g of water. The outer coating was applied onto the roofing granules using a fluidized bed coater Model 2 supplied by Fluid Air, Inc. (Aurora, Ill.). The operating conditions were set at 24 scfm of inlet air flow rate, 70° C. of inlet temperature, 10 psi of spraying pr...

example 2

Preparation of Encapsulated AR Granules

[0116]The process of Example 1 was repeated, except the outer coating composition was modified. The composition consisted of 188 g of sodium silicate (40% solids, with Na2O:SiO2 ratio of 1:3.2; Occidental Chemical Corporation, Dallas, Tex.), 100 g of clay slurry (70% solids, Unimin Corporation, New Canaan, Conn.), 20 g of titanium oxide (TiPure Product Number R-101, DuPont, Wilmington, Del.), 12 g of zinc oxide (Zinc Corporation of America, Monaca, Pa.) and 150 g of water. The coated granules were fired in a gas-fired kiln at a temperature of 500° C. for 20 minutes to form a composite roofing granule having cuprous oxide in the interior fully encapsulated by an exterior layer of zinc oxide-loaded sodium silicate binder. In this case, the resultant composite granules have dual algaecides: cuprous oxide in the interior and zinc oxide on the outer layer.

example 3

Preparation of Encapsulated AR Granules

[0117]The process of Example 1 was repeated, except the outer coating composition was modified further. The composition consisted of 60 g of colloidal silica Ludox CL-X (45% solids, pH 9.1, Sigma-Aldrich Corporation, St. Louis, Mo.), 30 g of clay slurry (70% solids, Unimin Corporation, New Canaan, Conn.), 12 g of aluminum phosphate (Sigma-Aldrich Corporation, St. Louis, Mo.), 20 g of titanium oxide (TiPure R-101, DuPont, Wilmington, Del.), 18 g of zinc oxide (Zinc Corporation of America, Monaca, Pa.) and 135 g of water. The coated granules were fired in a gas-fired kiln at a temperature of 500° C. for 20 minutes to form a composite roofing granule having cuprous oxide on the interior fully encapsulated by an exterior layer of zinc oxide-loaded phosphate binder. In this case, the resultant composite granules have dual algaecides cuprous oxide in the interior and zinc oxide on the outer layer.

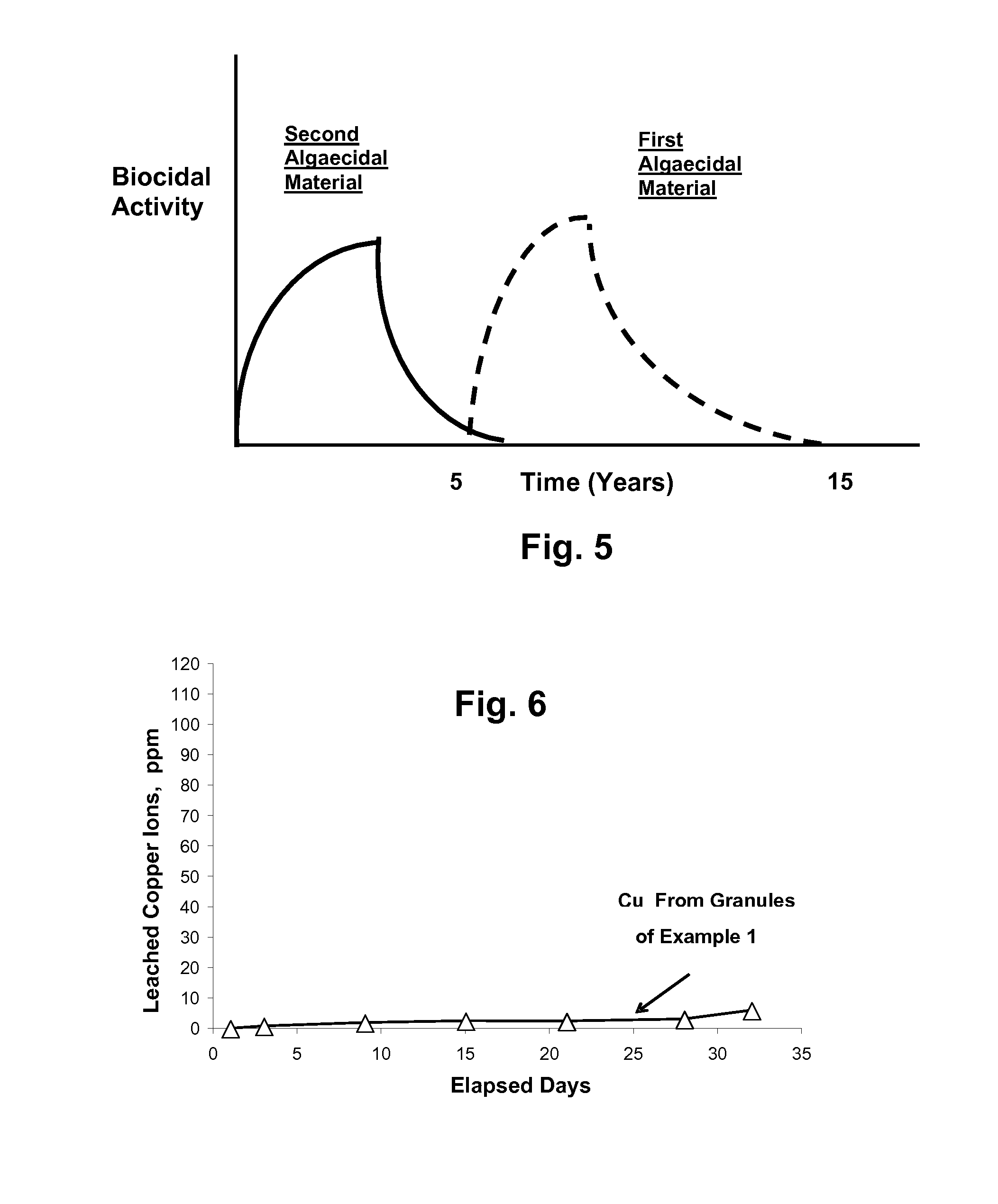

[0118]Leaching Procedure of Metal Ions from Roofing Gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com