Enhanced unitary sole assembly

a technology of unitary soles and soles, applied in the field ofsole assembly, can solve the problems of excessive rolling inward, underdeveloped arches may suffer from overpronation, and the foot may not pronate enough, and achieve the effect of facilitating the natural transition of impact and propulsion forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

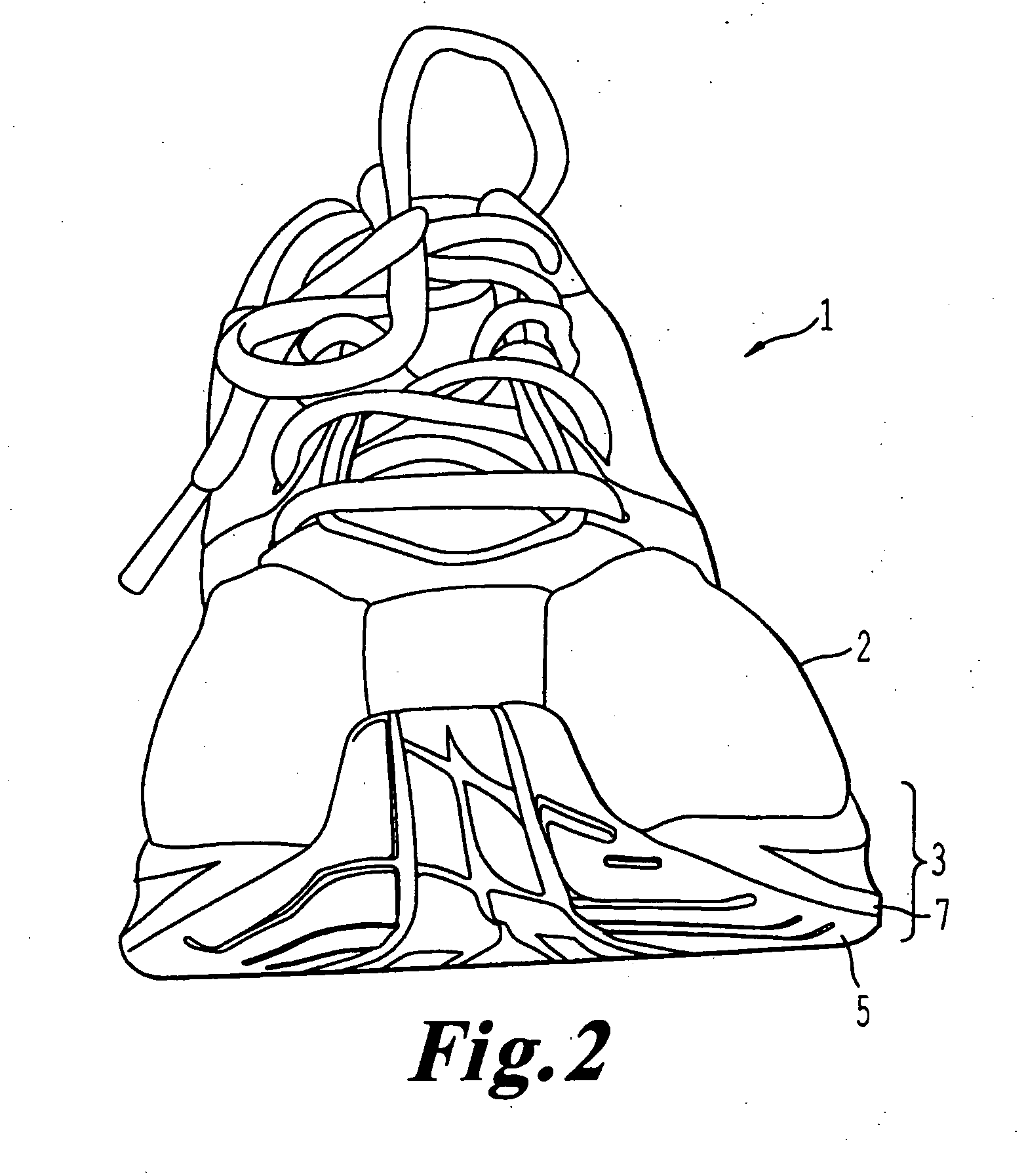

first embodiment

[0067]FIG. 6 shows a medial side view of the present invention. As shown in FIG. 6, the unitary midsole 7 has no hole on its medial side. Thus, the location of the lateral side hole 23 softens the lateral side of the sole assembly 3 relative to the medial side, thereby providing an effect similar to an arch support. The amount of support provided can be adjusted by changing the shape or thickness of the heel cradle 4, the hole frame 24, and the shape and size of the lateral side hole 23.

[0068]FIG. 7a depicts a rear view of the first embodiment of the present invention. In FIG. 7a, the heel hole 25 is positioned approximately in the center of the heel region, but with a slight bias toward the lateral side of the shoe. Thus, the heel hole 25 provides a centering effect, while also facilitating proper pronation of the foot by softening the lateral side of the unitary midsole 7, even if no heel cradle is present. If the heel cradle is present, the centering effect of the heel cradle 4 i...

third embodiment

[0077] Unlike the first two embodiments, the unitary midsole 7″ of the third embodiment does not have a lateral hole. The lateral side of the shoe 1″ is best shown in FIG. 19. The lateral hole may be omitted when the wearer has a tendency to underpronate. Thus, without the lateral hole, the lateral side of the unitary midsole 7″ is stiffer and the outside edge of the foot will compress the sole assembly 3 to a lesser extent.

[0078]FIG. 20 shows the sole assembly 3″ with medial hole 29″ and hole frame 24, but no fins 31. Thus, fins 31 are optional and are included when additional stiffness is required, or to enhance aesthetic appearance. Like the lateral holes described above, the medial holes are in fluid communication with the bottom hole 19. The inclusion of the medial hole 29″ enhances the effect of the exclusion of the lateral hole regarding pronation of the foot. In other words, a sole assembly 3″ with a medial hole 29″, but no lateral hole will typically have a stronger tendenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com