Modular structure for building panels and methods of making and using same

a module structure and building panel technology, applied in the field of improved structural and foundation system, can solve the problems of not being taught, prior art components do not appear to provide an integrated system capable of enduring the required load for an extended period of time, and prior art foundation systems generally preclude easy shipping and assembly of foundations, so as to reduce the processing of post-extrusion, reduce the cost, and the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

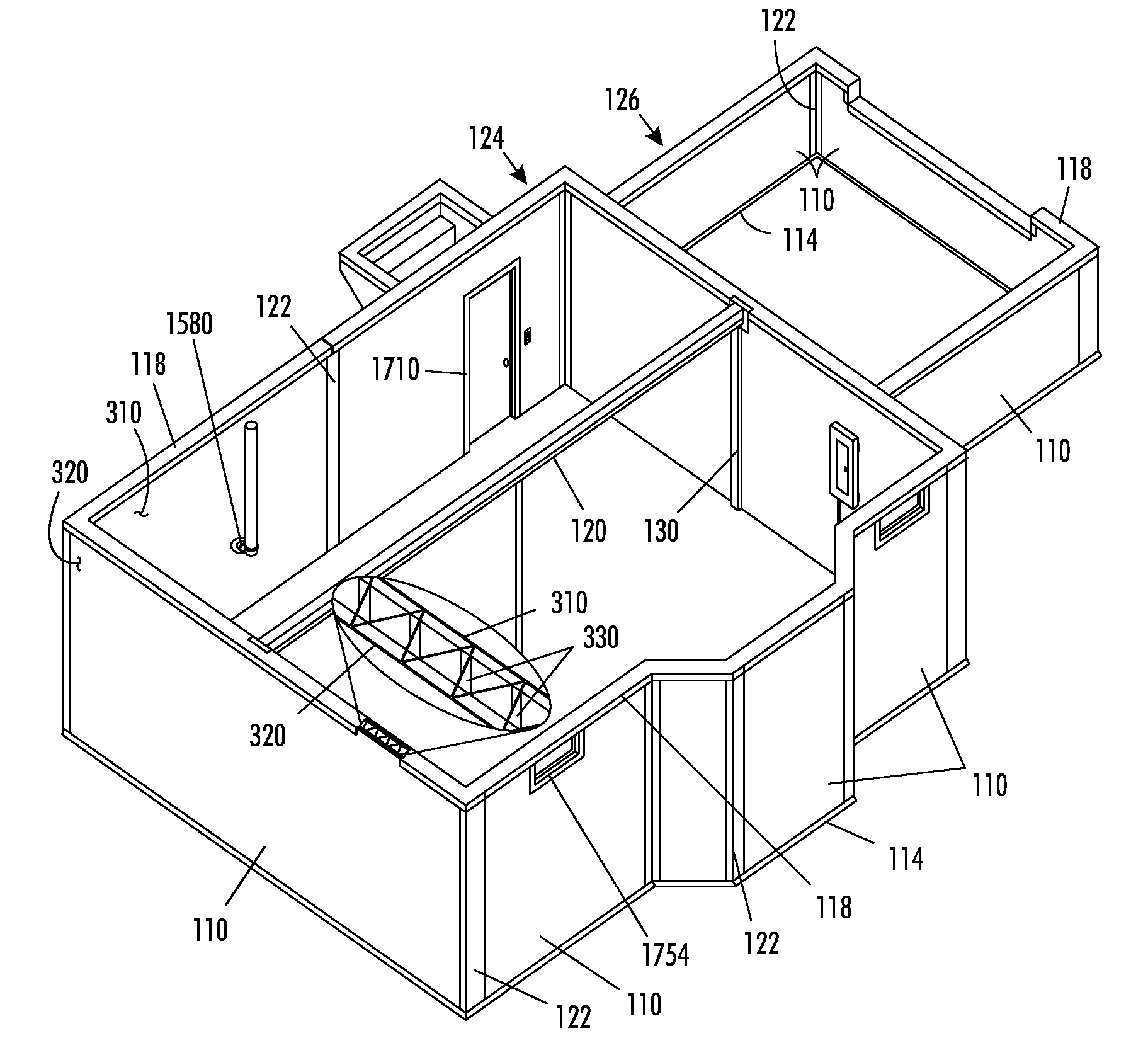

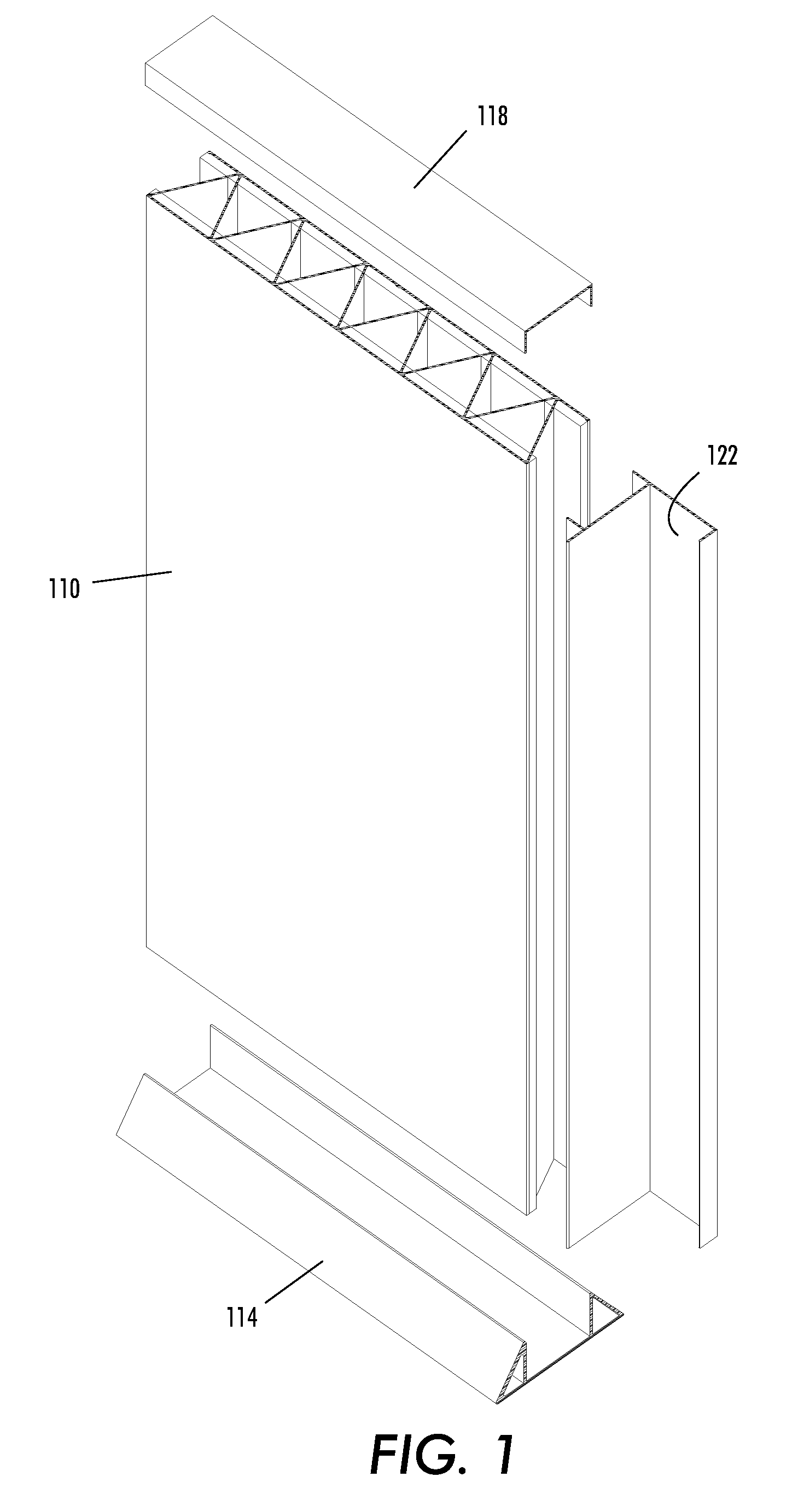

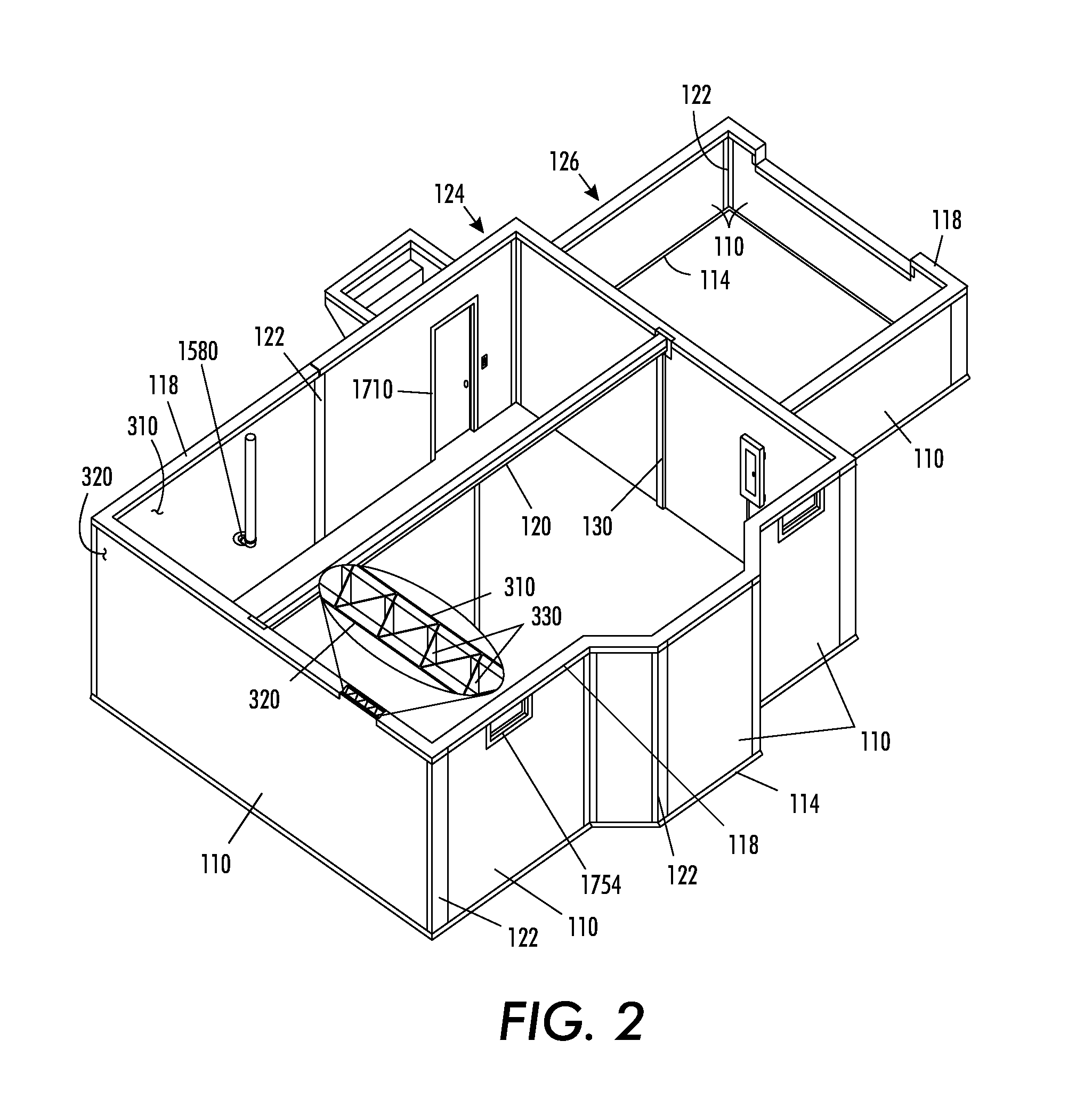

[0055] For a general understanding of the present invention, reference is made to the drawings. In the drawings, like reference numerals have been used throughout to designate identical elements.

[0056] As used herein the term “wall panel” is intended to include pre-manufactured panels comprising one or more materials formed to provide a finished or partially-finished surface or surfaces for the construction of structures, including but not limited to buildings, foundations for buildings and similar above and below-grade structures (e.g., retaining walls, noise barriers). It is further contemplated that the wall panel may be employed to produce pre-fabricated structural elements applicable for below-grade use such as pre-formed stair entryways, manholes, vaults, etc.

[0057] In the following description, an embodiment of the present invention is described relative to a polymeric material such as polyvinyl chloride (PVC), for example, a PVC resin may be used where no precompounding is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heights | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| rigidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com