Digital core workflow method using digital core image

a workflow method and digital core technology, applied in the field of formation depth determination methods, can solve the problems of inability to accurately determine the depth of the formation, easy errors, and time-consuming labeling process, and achieve the effects of reducing time expenditure, reducing labor intensity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

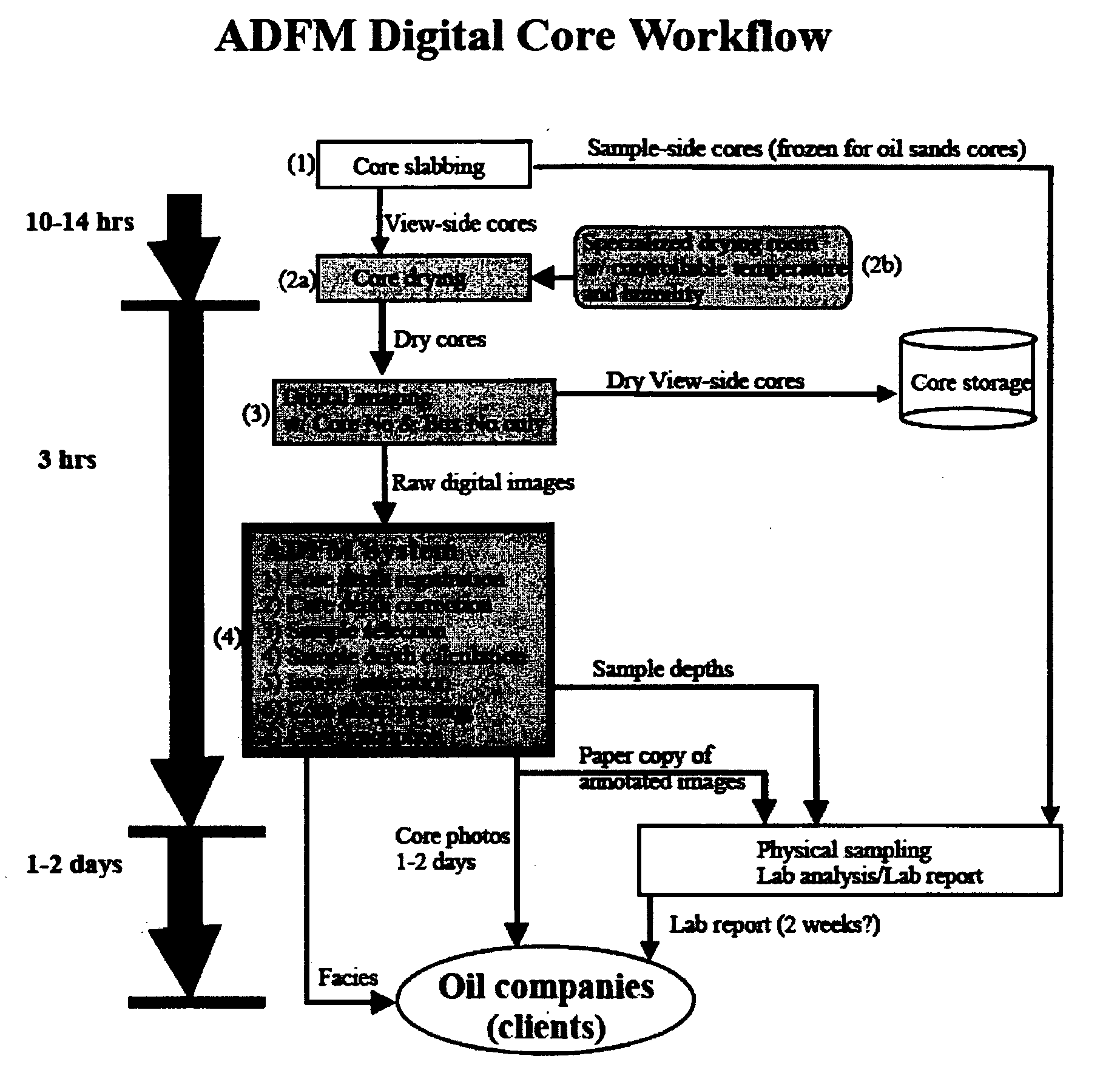

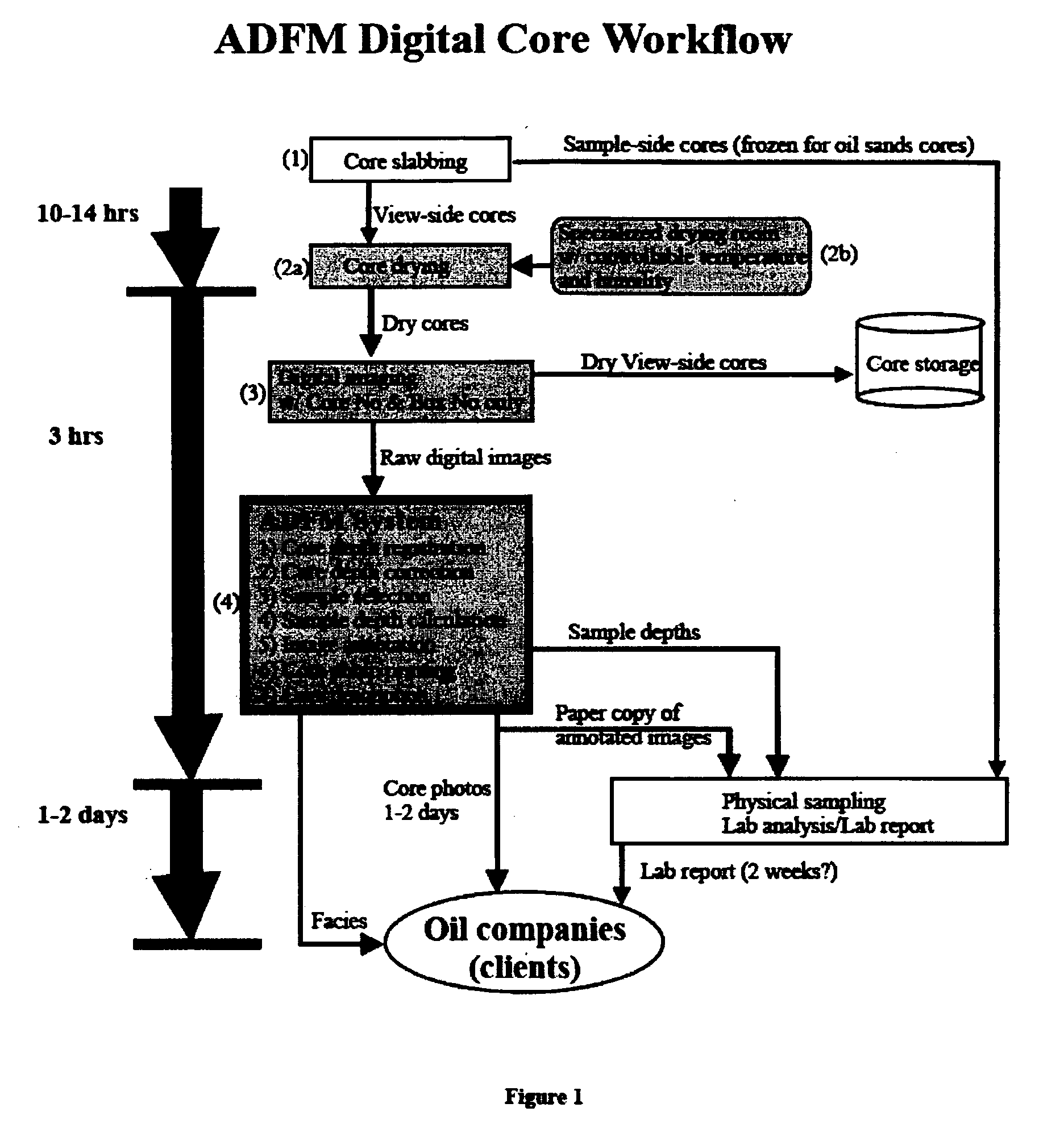

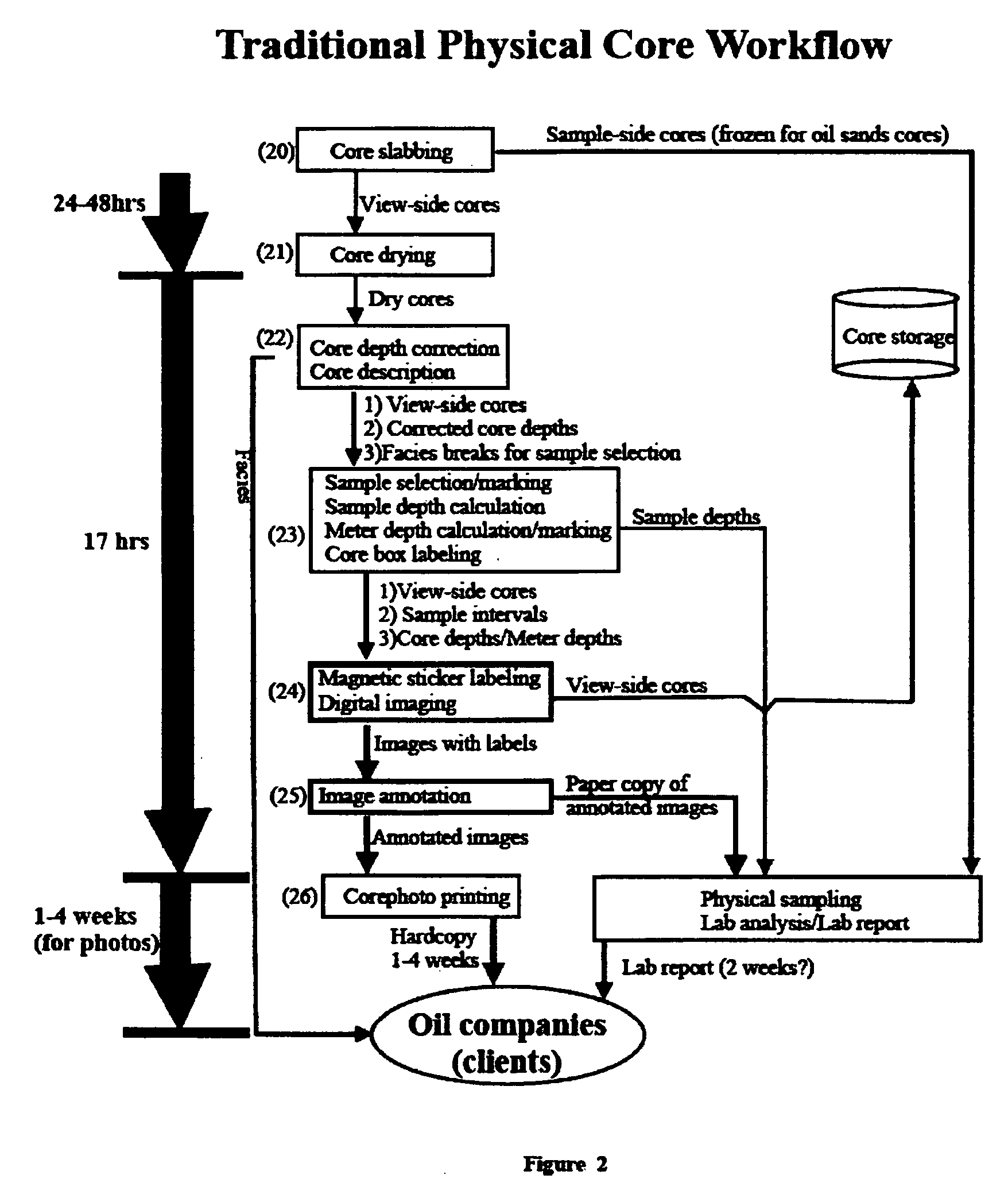

[0123] A preferred embodiment of the present invention will now be described with reference to the accompanying drawings. The preferred embodiment of the present invention will be described below by reference to an overall digital core workflow, which digital core workflow comprises a method and system referred to as ADFM™ (an acronym for “Accurate Depths for Facies and Modeling”).

Digital Core Workflow

[0124] Referring now in detail to FIG. 1, a digital core workflow is illustrated in accordance with the present invention. As can be seen, after cores (which may be frozen) are slabbed into two halves at step 1, the view-side cores are placed at step 2a into a specialized drying room 2b for approximately 10 to 14 hours to dry the cores, instead of simply displaying the cores in an ordinary core-view room. The specialized drying room 2b is tightly sealed after the doors are dosed and is separated from other ordinary view rooms or office rooms. The temperature in the room is settable,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com