Methods of fabricating and using shaped springs

a technology of interconnection elements and springs, which is applied in the manufacture of electrical instruments, printed circuit aspects, instruments, etc., can solve the problems of increasing the difficulty of determining limiting the design choices for the shape and metallurgy of the contact portion of the contact elements, and reducing the quality of the interconnection element. , to achieve the effect of increasing the spring constant of the interconnection elemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

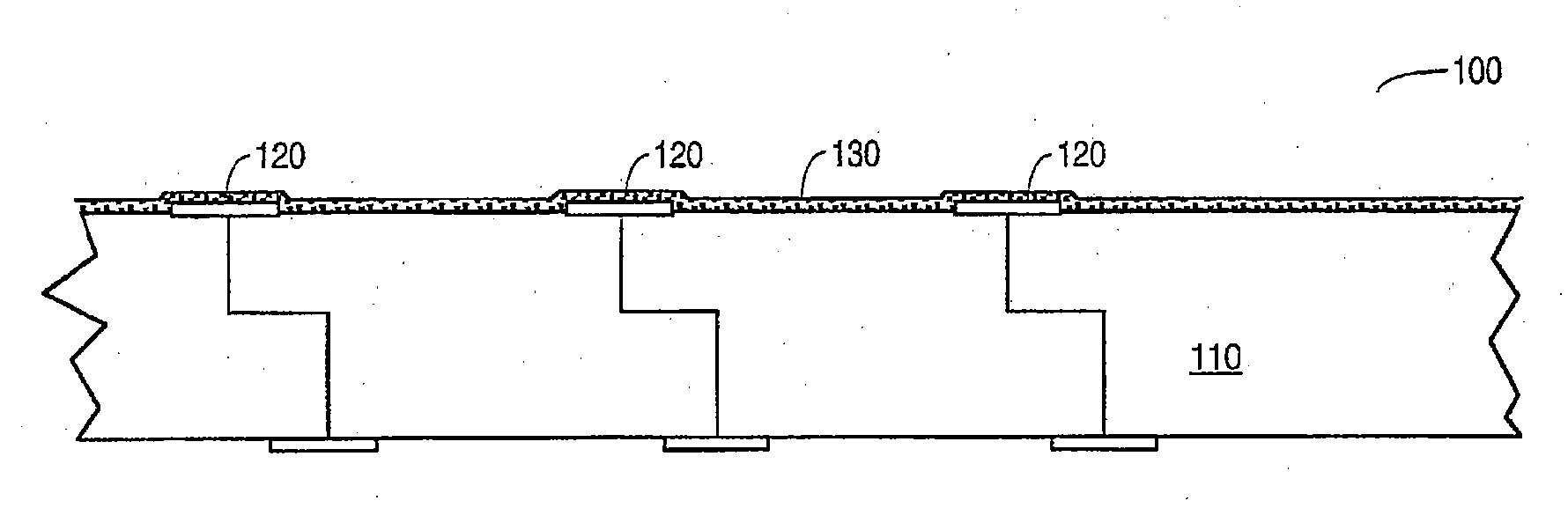

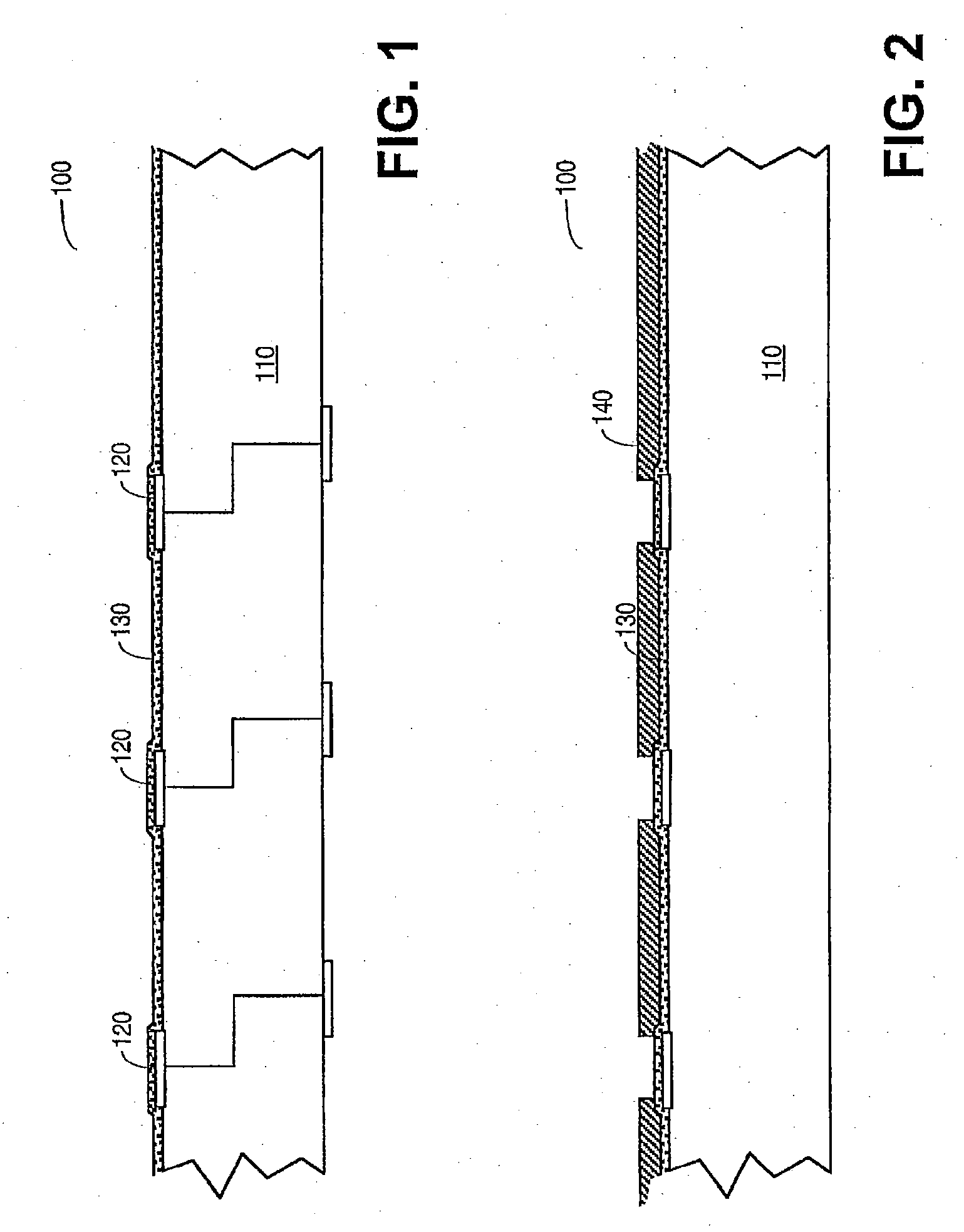

[0056] The invention relates to interconnection elements, including contact elements. According to one aspect of the invention, at least initially, an interconnection element includes at least two materials and one or both of the materials is adapted to undergo a transformation to deform the shape of the interconnection element. One example is a volume transformation of at least one of the materials from a first volume to a second, different volume, the volume transformation bringing about a change in the shape of the interconnection element. One advantage of the interconnection element of the invention is that such a structure may be formed with the desired shape, resilience, and spring constant according to a simplified technique.

[0057] In this manner, the invention describes an interconnection element having improved characteristics over prior art interconnection elements thus improving the suitability of the interconnection element of the invention for use in present and future...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com