Extraction of phytochemicals

a technology of extracts and phytochemicals, applied in the field of extracts of phytochemicals, can solve the problems of difficult scaling to commercial through-put volumes, phytochemicals are typically not soluble in water under ambient conditions, etc., and achieve the effects of increasing the dry weight basis percentage, and increasing the dry matter content of extracts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055] Flaxseed contains relatively high concentrations of phenolic compounds known as lignans that have demonstrated significant potential to reduce or prevent the incidence of various forms of cancer. The principle lignans in flax are secoisolariciresinol diglycoside (SDG) and SDG attached by an ester linkage to hydroxymethylglutaric acid (SDG-HMGA ester). Flaxseed also contains significant amounts of the phenolics coumeric acid, ferulic acid, chlorogenic acid and gallic acids, as well as flavonoids. These phytochemicals are typically extracted from flaxseed or flaxseed meal with aliphatic alcohols such as ethanol and methanol, after which the extract must be de-solventized before further processing or use.

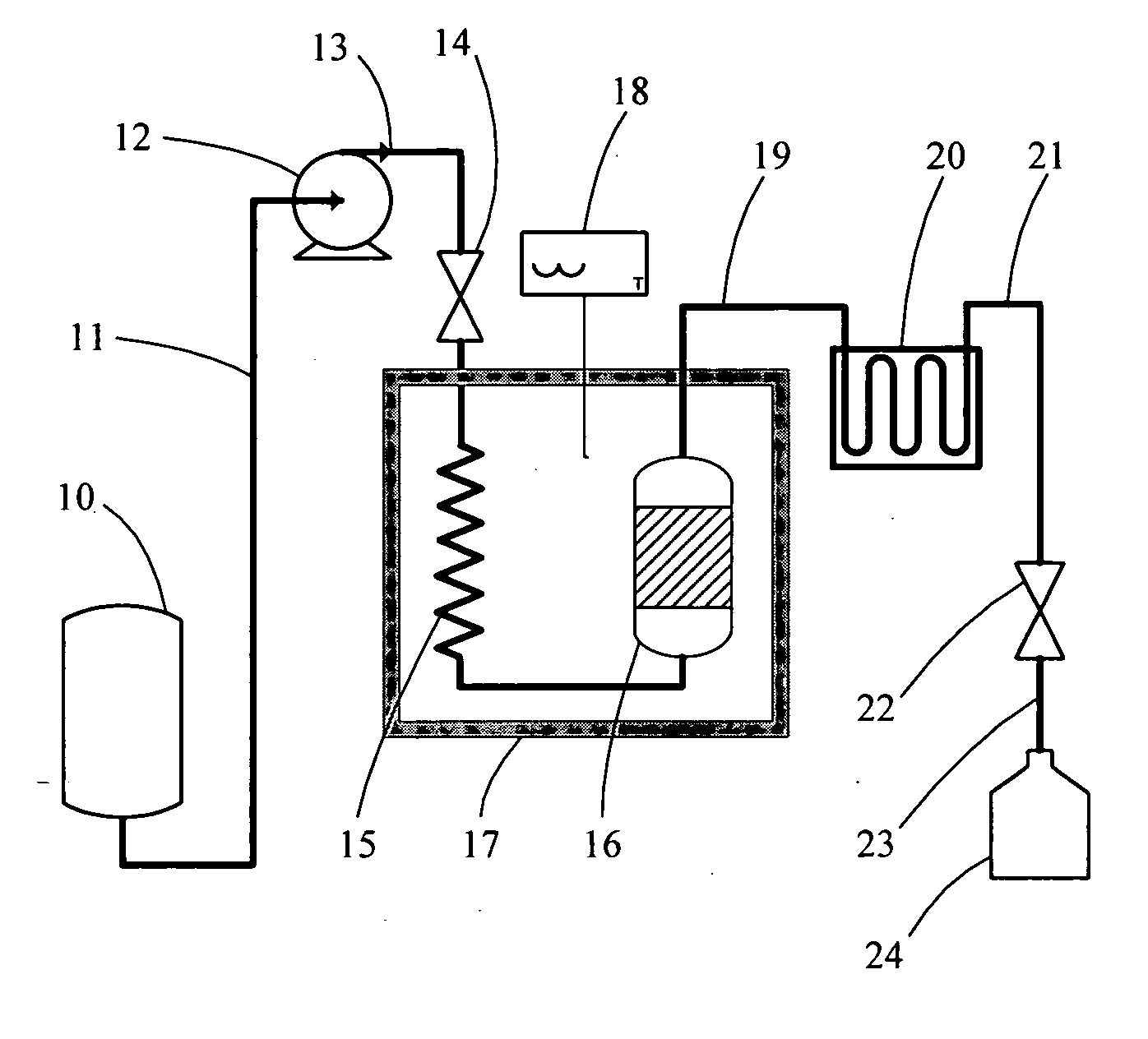

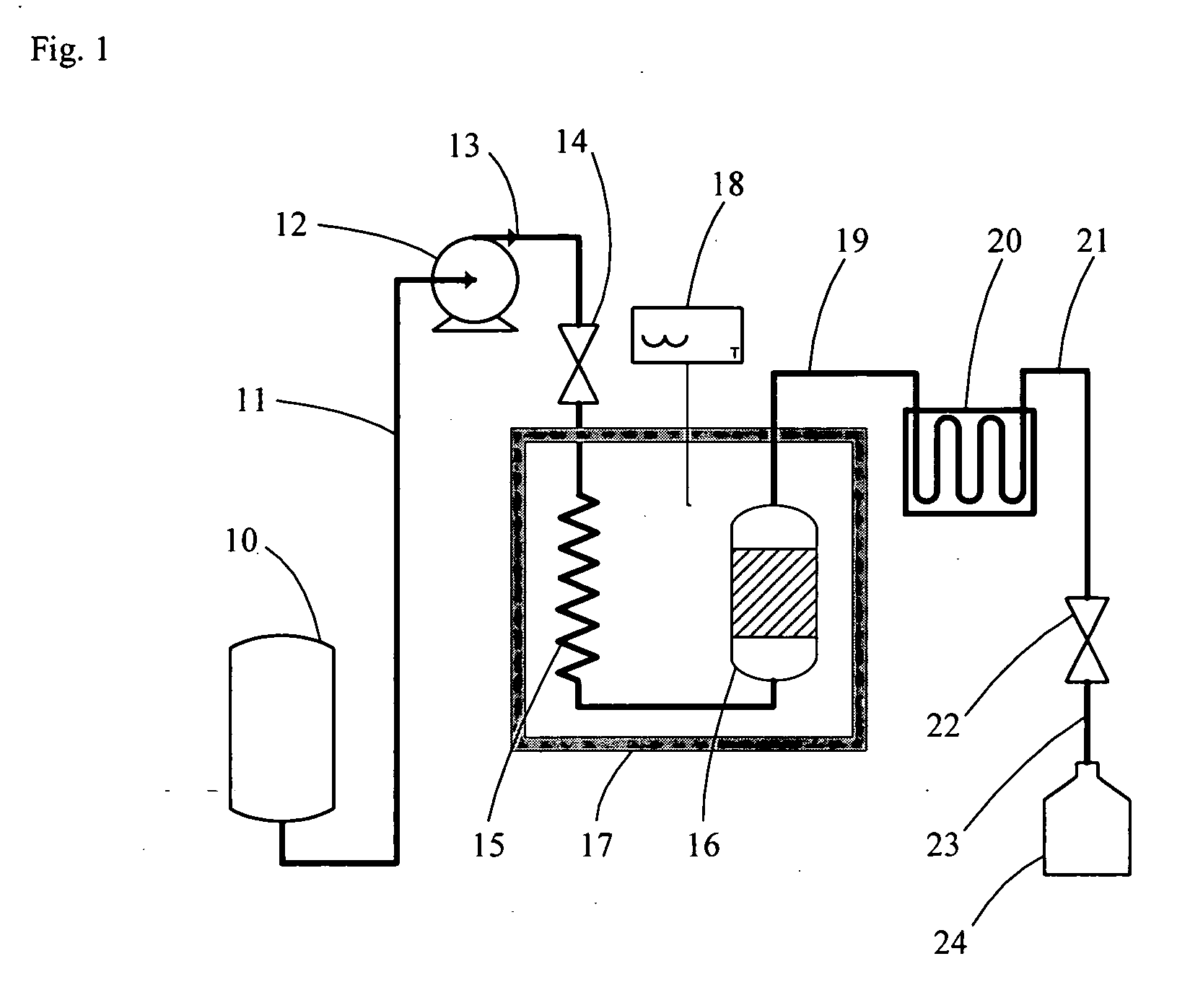

[0056] Lignans and other phenolic compounds were extracted from whole flaxseed with subcritical water using equipment and methods as described herein. Equipment included the following components: (a) a glass reservoir containing pure water, an HPLC pump (510 model, Waters, Milf...

example 2

[0068] The effects of four independent processing factors, i.e., pH, temperature, packing materials introduced into extraction vessels with source plant materials, and manipulating the liquid-to-solvent (L / S) ratio, on the extraction efficiencies of subcritical water were assessed with flaxseed meal as the source plant material for lignans, proteins, carbohydrates and other phytochemicals. The subcritical extraction equipment and system were configured as described in Example 1 and illustrated in FIG. 1. Since it is known that solvent pH significantly affects the solubilities and extraction efficiencies of protein extractions, three volumes of pure water were adjusted individually to pHs of 4, 6.5, and 9, and were separately assessed in these studies. Increasing extraction temperatures were also assessed with each volume of pH-adjusted pure water to determine optimal extraction rates for lignans while avoiding their thermodegradation. Preliminary studies compared the suitability of ...

example 3

[0074] Cow cockle (Sapponaria vaccaria L.) seeds were used as source plant material to assess the usefulness of the present invention for subcritical water co-extraction of saponins with carbohydrates. The system was configured as illustrated in FIG. 1 and included the following components: (a) a glass reservoir containing pure water, an HPLC pump (515 model, Waters, Mississauga, ON, Canada), (b) a 4.0-m preheating coil, (c) an extraction vessel, (d) a temperature-controlled oven (5700A Series, Hewlett-Packard, Palo Alto, Calif., USA), (e) a 1.0-m cooling coil, (f) a back-pressure regulator with a 750-psi cartridge (Scientific Products and Equipment, Concord, ON, Canada), and (g) multiple collection vessels for receiving sequential extract volumes. The components were interconnected with stainless steel tubing having a 1.25-mm outer diameter (o.d.) using fittings adequate to withstand high pressures. Components (b) and (c), i.e., the preheating coil and extraction vessel, were mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com