Airflow generating structure and the apparatus thereof

a technology of airflow and generating structure, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of increasing noise and vibration, shortening the service life, etc., and achieves the effect of reducing noise, reducing noise, and increasing rotational velocities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

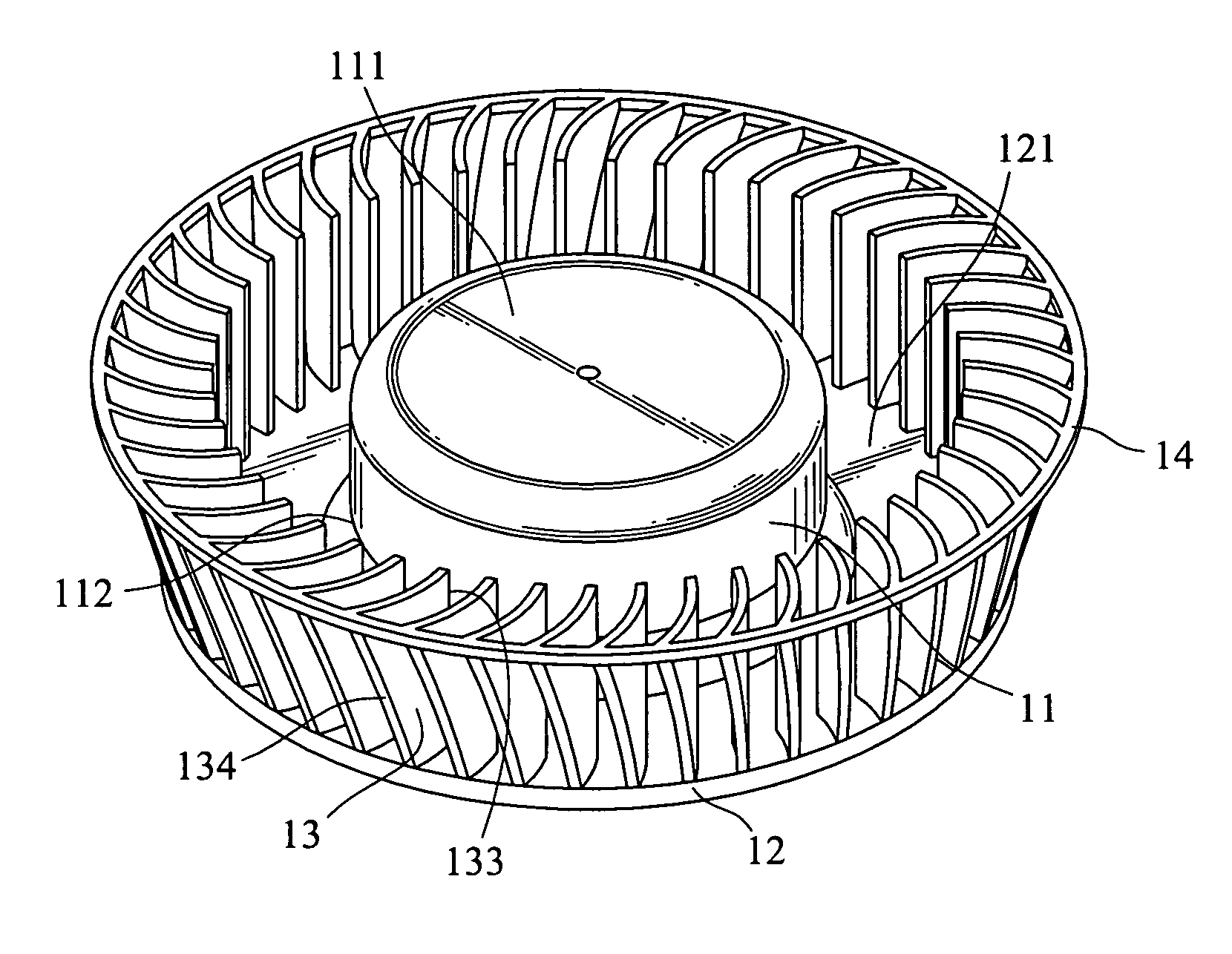

[0030] Referring to FIGS. 5 and 6 for the invention, the airflow generating structure 10 includes a hub 11, a holding section 12, a plurality of spoilers 13 and a stabilization ring 14.

[0031] The hub 11 has a top end 111 and a bottom end 112. The top end 111 is substantially formed in a convex shape. The bottom end 112 has a concave portion 113 to hold a spindle 15 protruding outwards.

[0032] The holding section 12 is substantially an annular plate integrally formed on the periphery of the bottom end 112, and is extended outwards from the hub 11, and has a holding surface 121 on one side, facing upwards.

[0033] Each of the spoilers 13 has a convex surface and a concave surface to form a curved profile. Each spoiler 13 has a root 131 and a tip 132, and has a height approximated to that of the hub 11. The root 131 is fastened to the holding section 12. The spoilers 13 are located round the periphery of the holding section 12 in an equally-spaced manner. The tip 132 is remote from the ...

second embodiment

[0046] Refer to FIG. 11 for the invention that provides an airflow generating structure 40 with an improved air channeling effect. It includes a hub 41, a holding section 42, a plurality of spoilers 43 and a stabilization ring 44 that are largely like those previously discussed. The main distinction of the two is that there is a round angle 45 formed between the juncture of the holding section 42 and the hub 41. Hence when the airflow passes rapidly from the upper side of the hub 41 towards the holding section 42, the round angle 45 can channel the airflow smoothly to the periphery of the holding section 42 and discharge the airflow through the lower side of the hub 41, to avoid directly hitting the holding section 42. Hence kinetic energy loss of air can be reduced, and the flow rate and dynamic pressure can be maintained without dropping too much.

[0047] Refer to FIG. 12 for a third embodiment of the invention that provides an airflow generating structure 50 with an improved air ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com