Plasma arc torch providing angular shield flow injection

a technology of angular shield and arc torch, which is applied in the field of plasma arc torch, can solve the problems of degrading cutting, piercing or marking performance, plasma gas having difficulty cooling the tip of the nozzle, and less protection from reflecting slag, so as to achieve stable ionized plasma gas flow, effective cooling, and effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

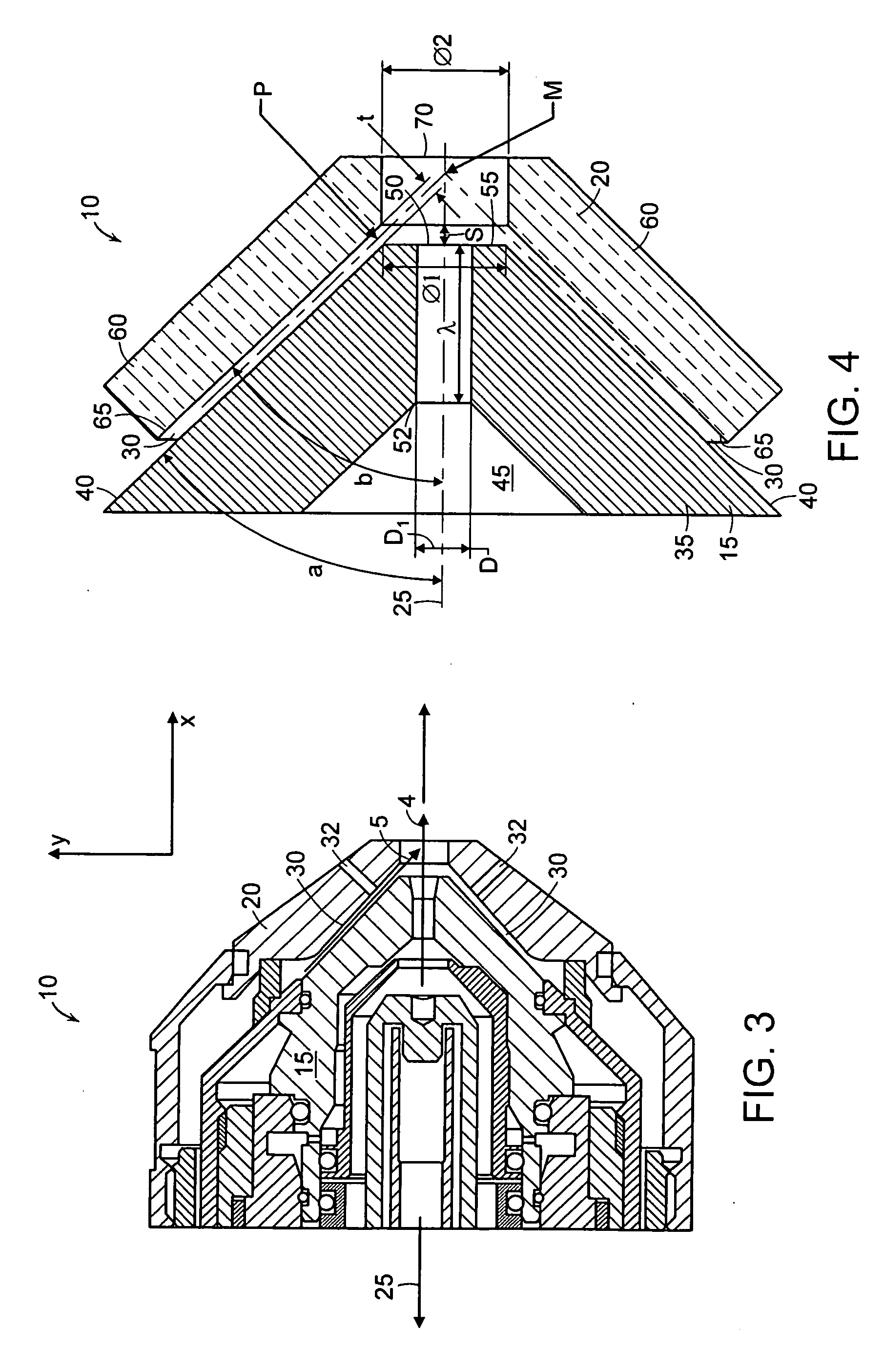

[0044] A torch tip having a substantially conical exterior nozzle portion and a substantially conical interior shield portion was modeled using thermal analysis and the results were compared to a model of a conventional torch tip that provided columnar flow. Referring to FIGS. 7 and 8, FIG. 7 shows the thermal analysis results for the torch tip that provided columnar flow and FIG. 8 shows the thermal analysis results for the torch tip that provides angular flow of 42.5 degrees. Both the prior art torch tip and the torch tip of in accordance with the invention had a L / D of 2.6, a φ1 / D of 2.1, and a φ2 / φ1 of 1.03.

[0045] As shown in FIG. 7, the torch tip having columnar flow experiences a maximum temperature of 996 degrees C., whereas the torch tip providing angular flow (FIG. 8) experiences a maximum operating temper of 696 degrees C. under equal heat loading. As a result, the torch tip of the present invention provides better conduction of heat away from the nozzle during use. Thus,...

example 3

[0046] A torch tip having a substantially conical exterior nozzle portion and a substantially conical interior shield portion can be used to cut ¾ inch mild steel on a dross-free speed of up to 100 ipm. Both the substantially conical exterior nozzle portion and the substantially conical interior shield portion had a half-cone angle of 30 degrees. Each of the shield and the nozzle are machined from copper and include o-rings to secure the torch tip to the plasma arc torch. The shield has twelve vent holes disposed therein to provide additional cooling.

[0047] The shield and the nozzle are mounted with respect to each other along the longitudinal axis at a distance of 0.04 inches to form a passageway having a thickness of 0.020. The velocity of the shield gas (air) as it exited the passageway at point P is 2,500 inches per second. The exit orifice of the nozzle has a length L of 0.234 inches, a diameter D of 0.0867 inches, and a nozzle end face diameter φ1 of 0.18 inches. As a result,...

example 4

[0048] A torch tip having a substantially conical exterior nozzle portion and a substantially conical interior shield portion can be used to cut ¾ inch mild steel on a dross-free speed of up to 100 ipm. Both the substantially conical exterior nozzle portion and the substantially conical interior shield portion had a half-cone angle of 47 degrees. Each of the shield and the nozzle are machined from copper and include o-rings to secure the torch tip to the plasma arc torch. The shield has twelve vent holes disposed therein to provide additional cooling.

[0049] The shield and the nozzle are mounted with respect to each other along the longitudinal axis at a distance of 0.03 inches to form a passageway having a thickness of 0.022. The velocity of the shield gas (air) as it exited the passageway at point P is 5,000 inches per second. The exit orifice of the nozzle has a length L of 0.234 inches, a diameter D of 0.0867 inches, and a nozzle end face diameter φ1 of 0.208 inches. As a result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| half-cone angle | aaaaa | aaaaa |

| half-cone angle | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com