Method and System for controlling coal flow

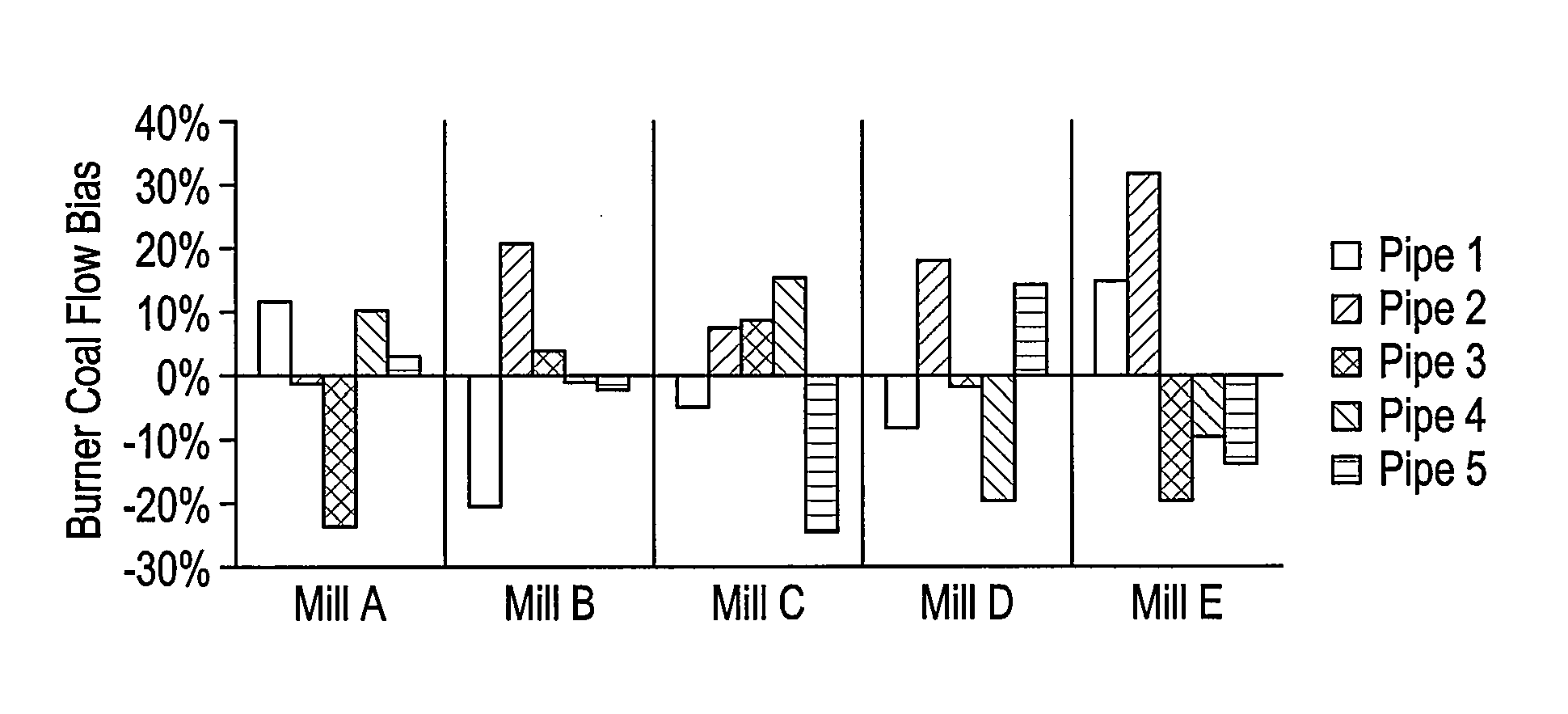

a technology of flow control and coal flow, applied in the direction of combustion control, solid fuel combustion, lighting and heating apparatus, etc., can solve the problems of reduced combustion efficiency, physical differences, and poor balance of pulverized coal distribution between burner pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

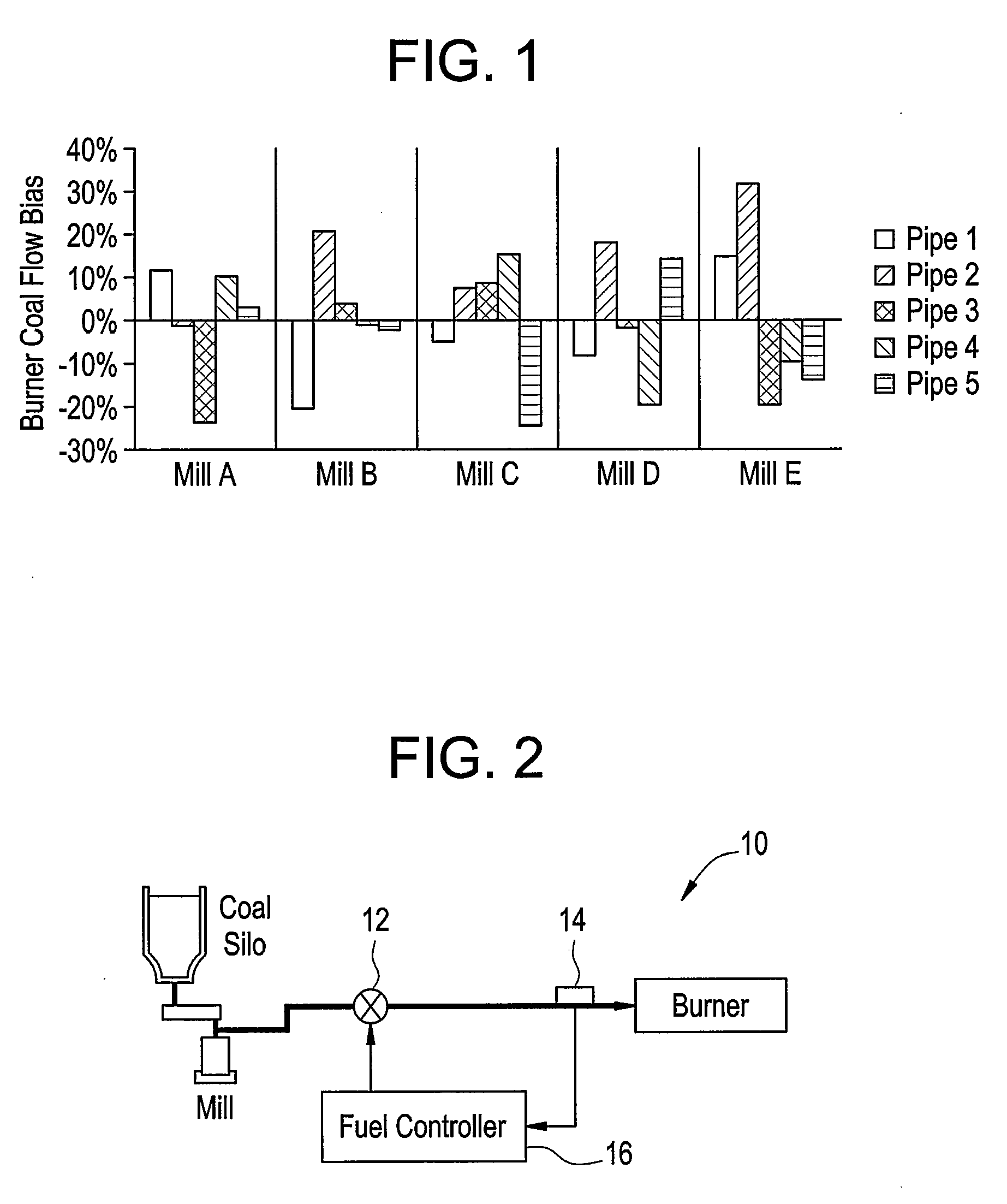

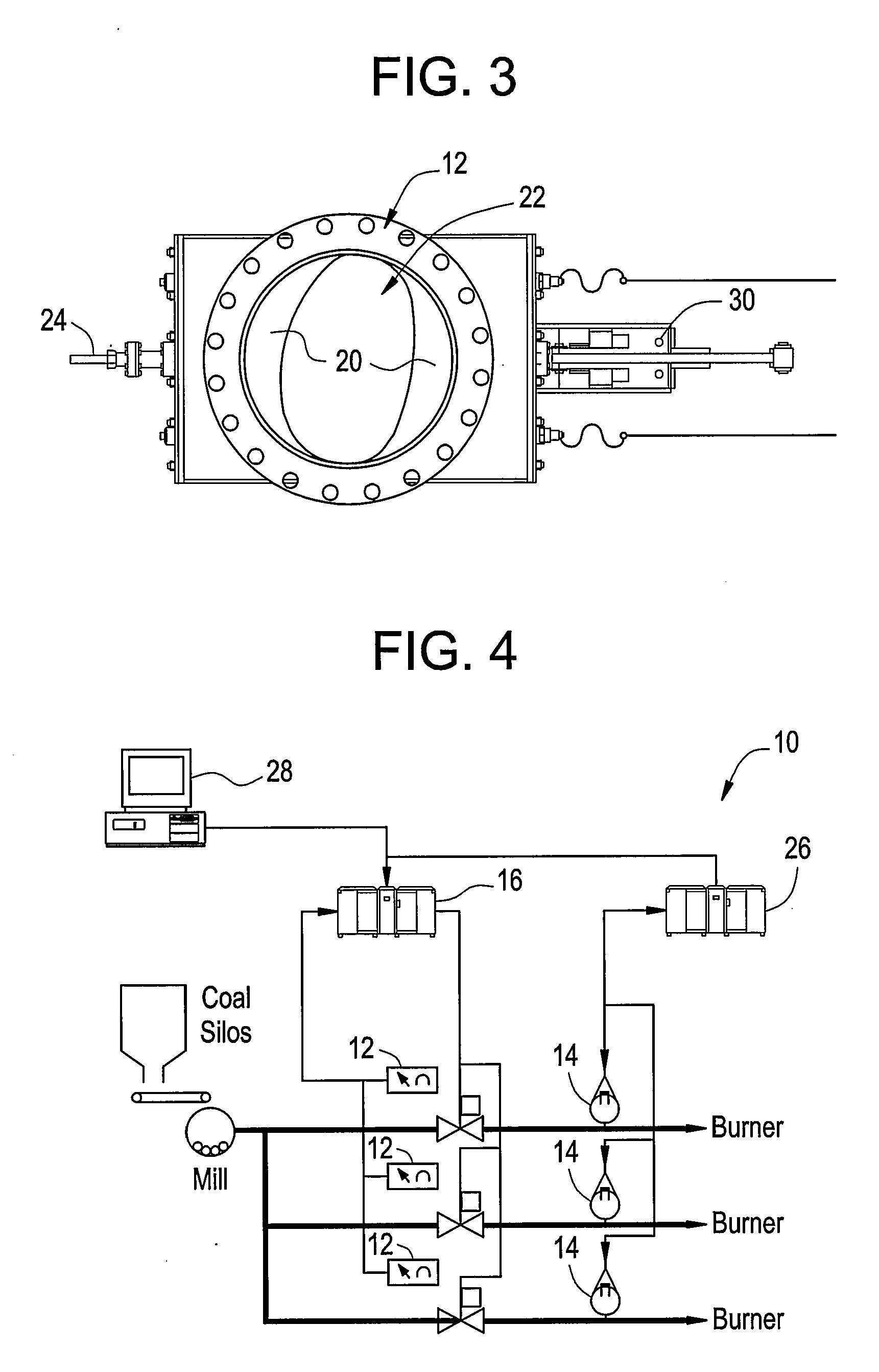

[0019] In coal fired boilers, balanced coal flow among burners is traditionally an important factor for combustion optimization. In order to effectively optimize furnace combustion performance, coal flow to each individual burner must be closely controlled. Coal flow control can be accomplished automatically and continuously through the use of a coal flow control system. Referring to FIG. 2, an exemplary embodiment of the coal flow control system is shown generally at 10. A coal flow sensor 14 measures the coal flow in a burner pipe and communicates a coal flow signal, indicative of coal flow in the burner pipe, to a fuel trim controller 16. A coal flow damper 12 controls the coal flow in the burner pipe and receives command signals from the fuel trim controller 16. The coal flow damper 12 is discussed in more detail hereinafter with reference to FIG. 3. The fuel trim controller 16 receives the coal flow signal from the coal flow sensor 14 and input signals from a controller, indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com